Pressure fatigue test stand test piece fixing device

A technology for fatigue testing and fixing devices, applied in measuring devices, testing of machines/structural components, instruments, etc., can solve problems such as strength reduction, material fatigue failure, safety issues, etc., and achieve the effect of easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

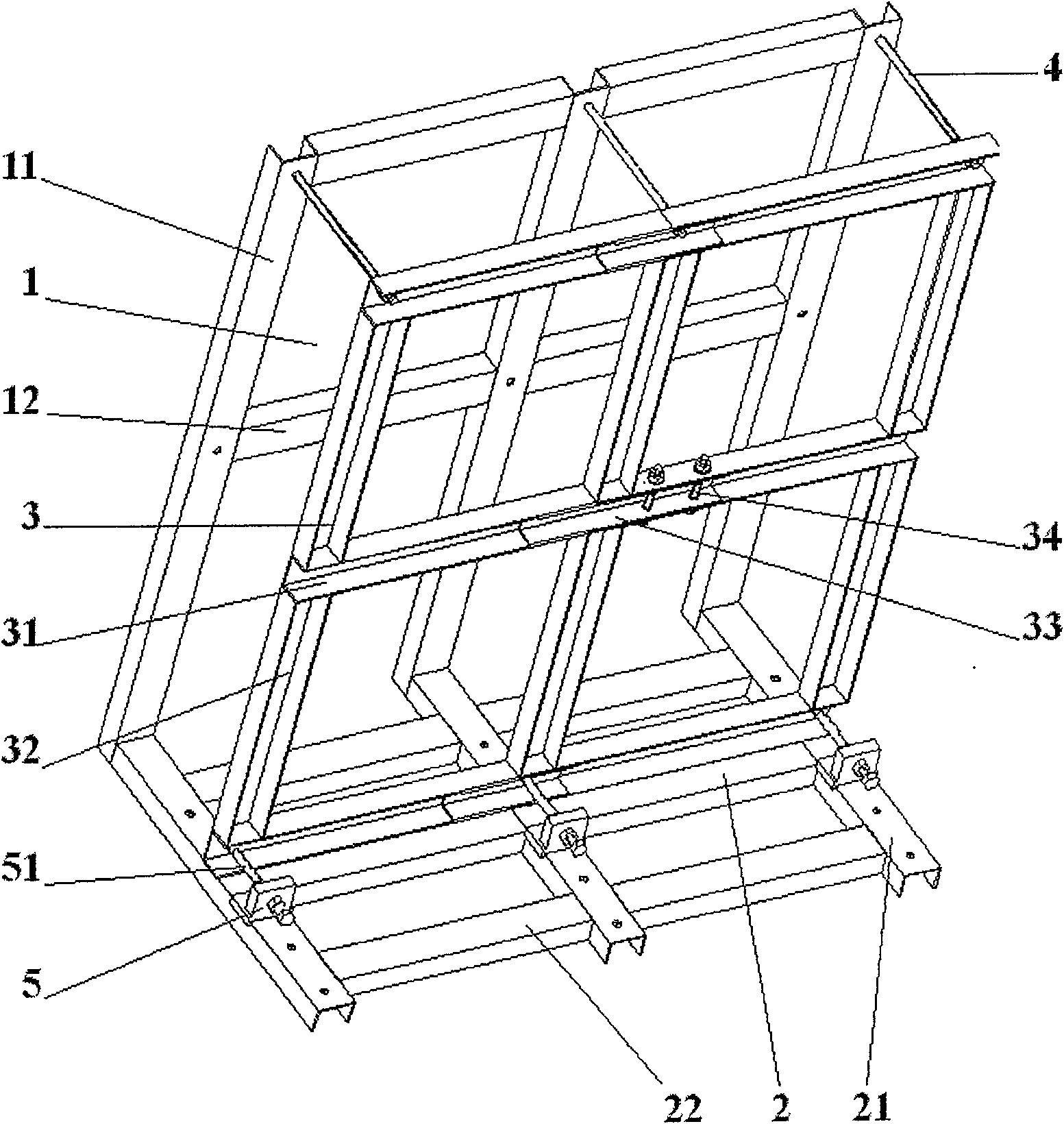

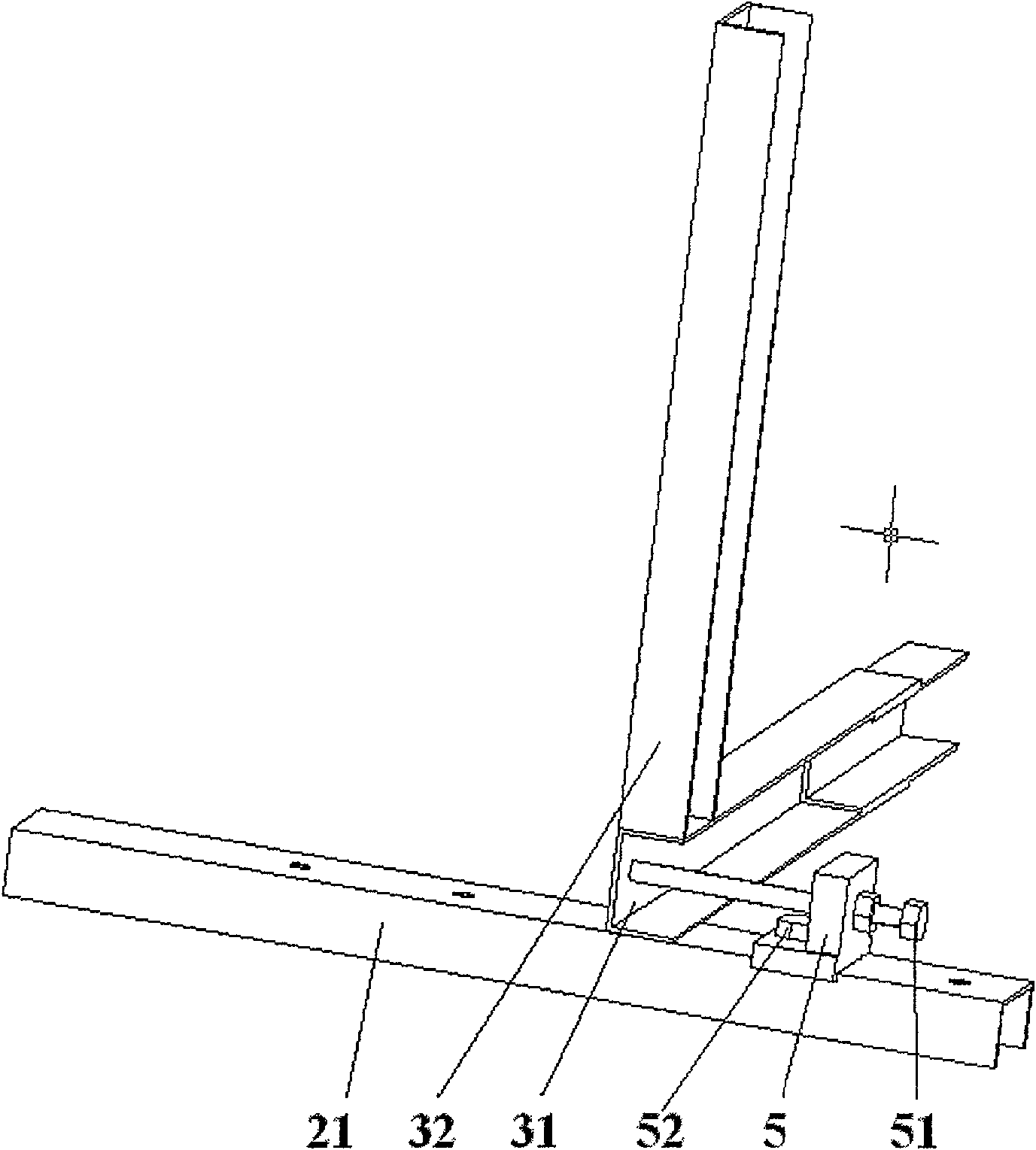

[0014] The pressure fatigue test bench test piece fixing device of the present invention consists of a backboard column 11 and a backboard beam 12 to form a backboard 1, a base longitudinal beam 21 and a base beam 22 to form a base 2, and a splint beam 31 and a splint column 32 to form a splint 3; The upper part of the plate 1 is connected to the upper part of the splint 3 through the tie rod 4, the lower part of the back plate 1 is connected to one end of the base 2, and the lower part of the splint 3 is connected to the middle part of the base 2; the lower part of the limit block 5 is connected to the base 2, and the limit The movable push rod 51 on the block 5 is connected with the bottom of the splint 3 . The splint 3 is made up of two symmetrical parts, that is, the outside is the splint column 32, and the inside is the upper, middle and lower three splint beams 31. Limiting block 5 is right-angled, and its lower plane is fixed on the base 2 by bolt pair 52, and its verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com