Equipment for spring production

A kind of equipment and station technology, applied in the field of spring production and processing equipment, can solve the problems of high processing cost, too small mechanical arm length, time-consuming and labor-intensive operation, etc., to ensure processing accuracy, avoid hard impact, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

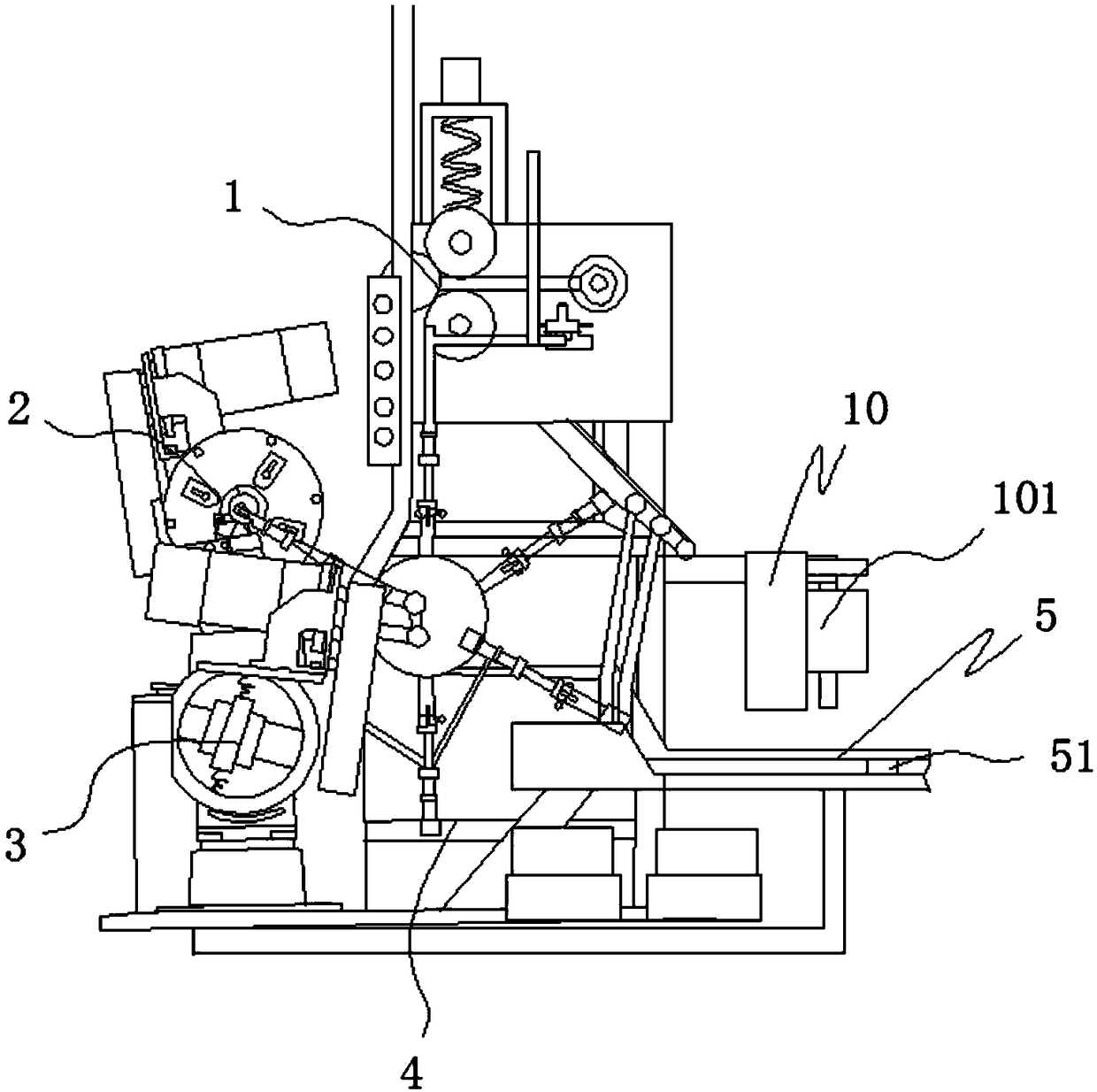

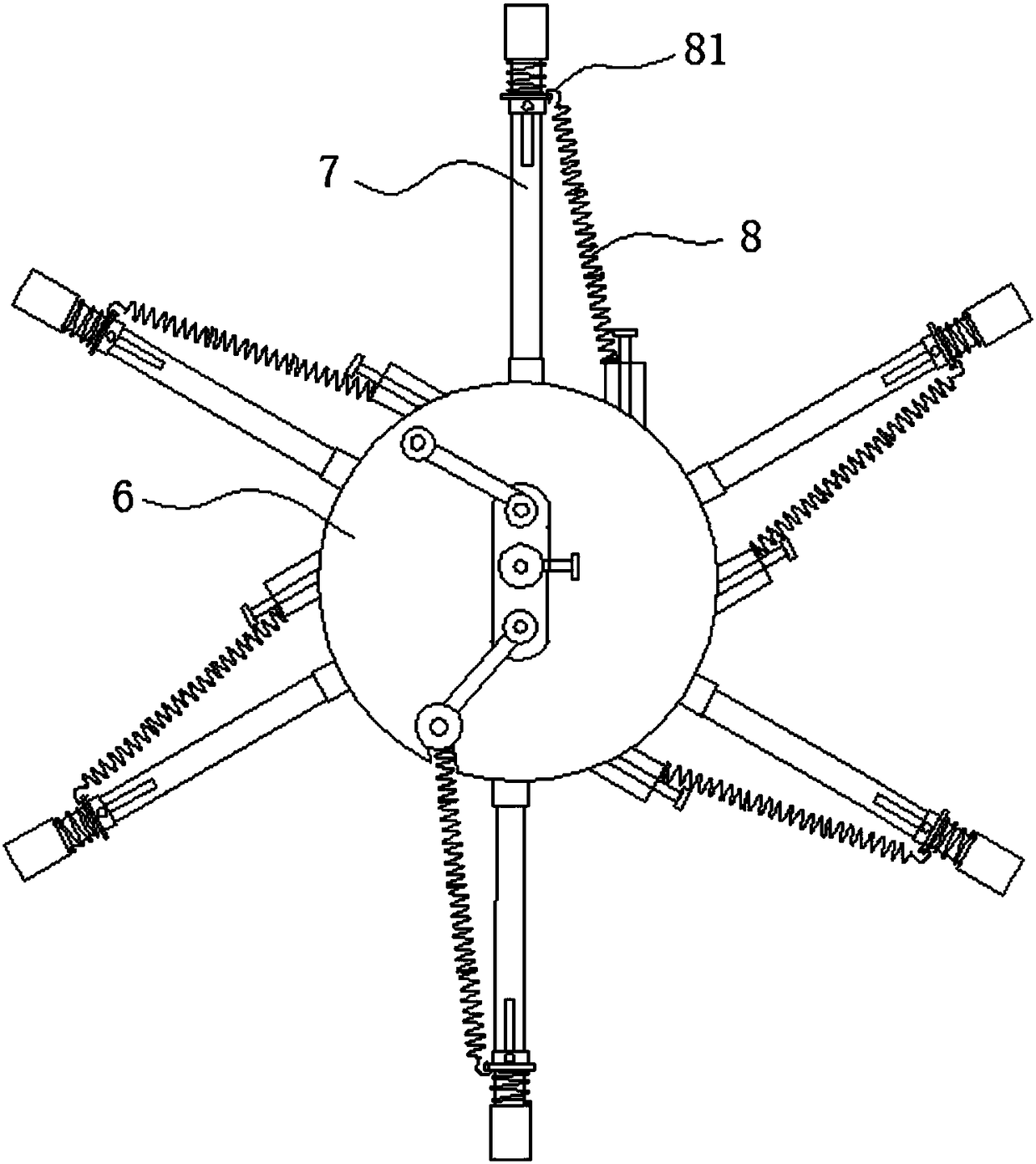

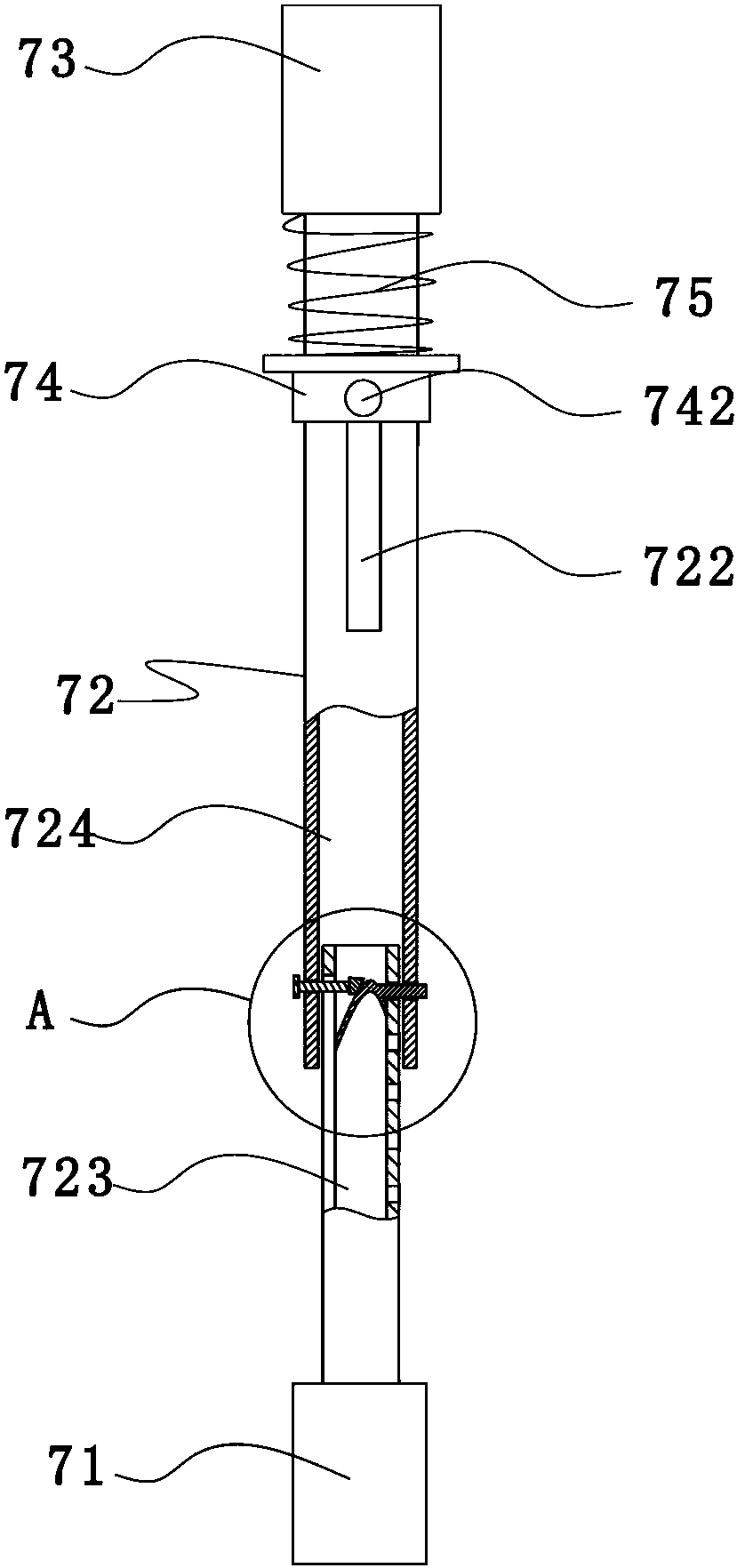

[0018] Such as Figure 1-5 As shown, a device for spring production and processing includes a center turntable, a coil spring station 1, an upper knotting station 2, a lower knotting station 3, a heat treatment station 4, a discharge station 5, and a cooling station. Bit 10; Specifically, the center turntable includes a disk body 6, a plurality of mechanical arms 7 evenly spaced on the disk body, an elastic telescopic part 8 matched with the mechanical arms, and a drive for driving the disk body to rotate The driving part is a motor directly purchased on the market, which can be used to drive the disc body; the mechanical arm 7 is made of metal as a whole, and the mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com