A jet printing spacing regulating and controlling method based on near field electrospinning jet printing multi-needle array experiments

A multi-needle, jet printing technology, applied in electric speed/acceleration control, textile and papermaking, fiber processing, etc., can solve the problems of increasing cost, low printing efficiency, adding human error factors, etc., to achieve cost savings, Guaranteed accuracy and reliable experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

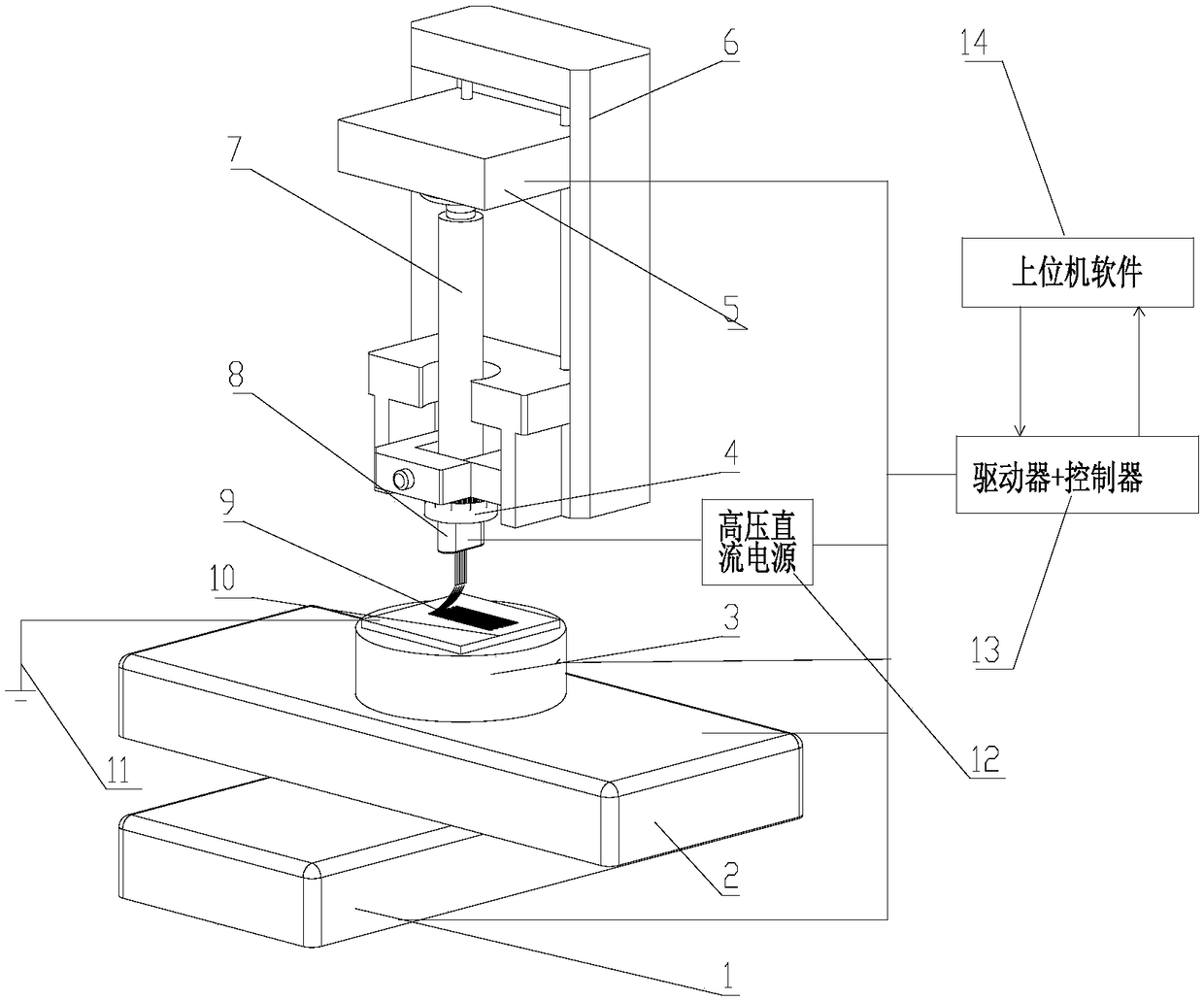

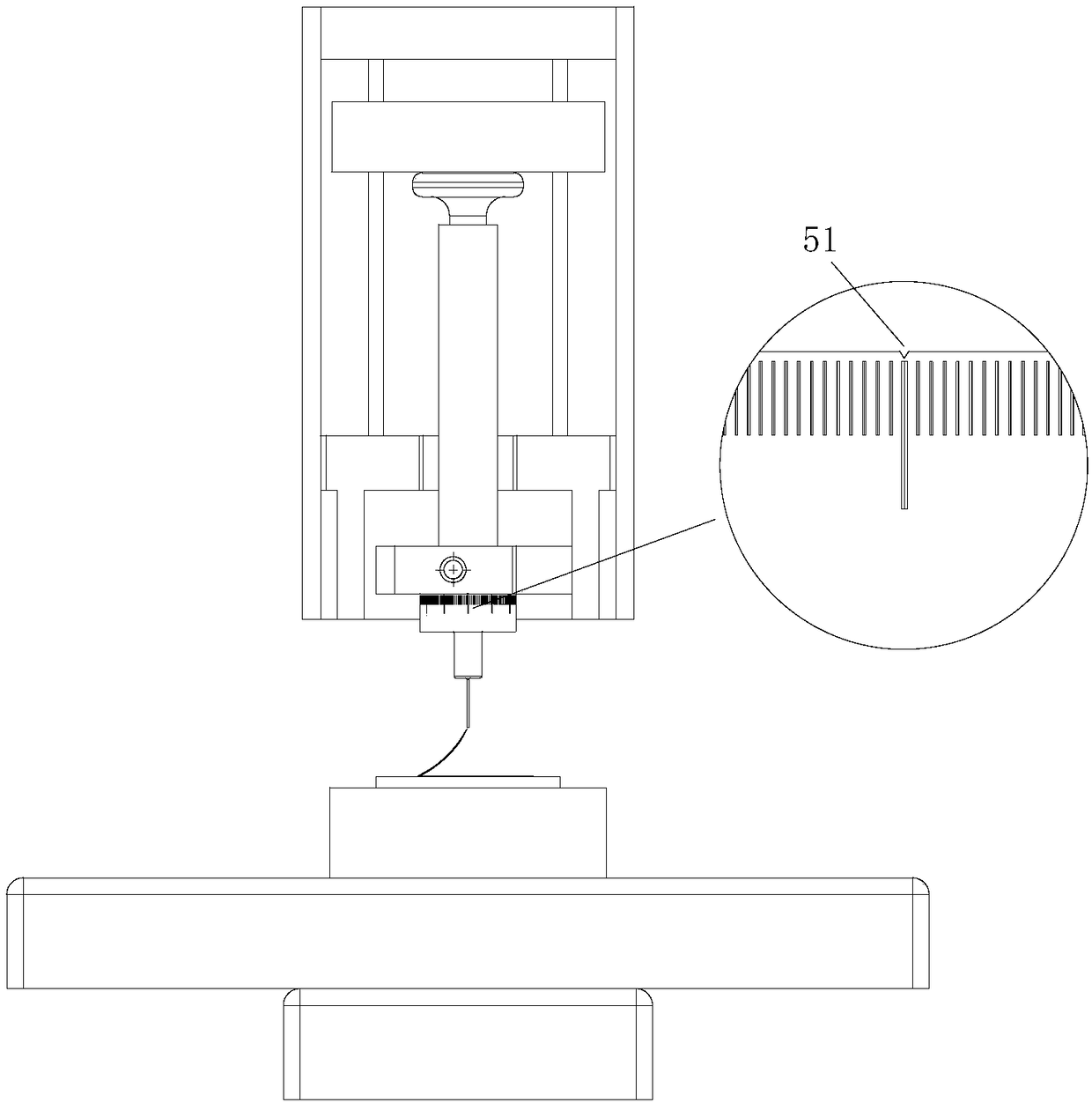

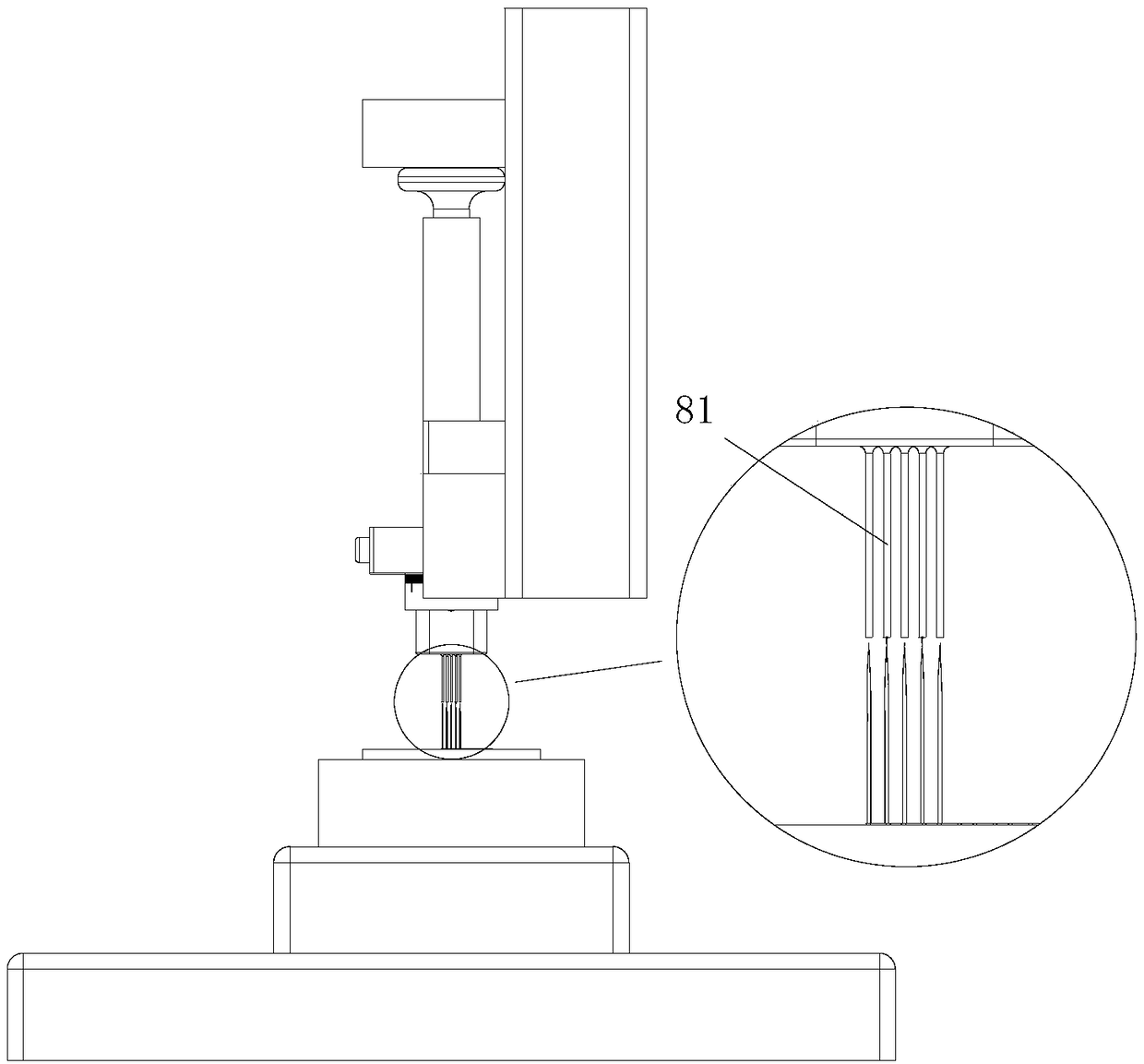

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention discloses that the present invention is a spray printing spacing control method based on near-field electrospinning jet printing multi-needle array experiments. During the application process of near-field electrospinning jet printing technology, due to the The efficiency of jet printing is low, so some college researchers gradually began to explore the near-field multi-needle array jet printing experiment, and when exploring the multi-needle array jet printing, sometimes it is necessary to ensure that the arrangement direction of the needles 81 is perpendicular to the direction of the traction axis Sometimes it is necessary to explore the printing effect of different needle pitches, so it is usually necessary to customize the needle heads 81 arranged in arrays of various needle pitches. For the same exploratory experiment, repeated replacement of needles 81 will add a human error f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com