A double-planet row multi-stage multi-clutch hydraulic-mechanical continuously variable transmission

A continuously variable transmission, hydraulic machinery technology, applied in mechanical equipment, vehicle gearboxes, multi-gear ratio transmissions, etc., can solve the problems of increased cost, difficult operation, and increased complexity of the mechanical structure of the transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

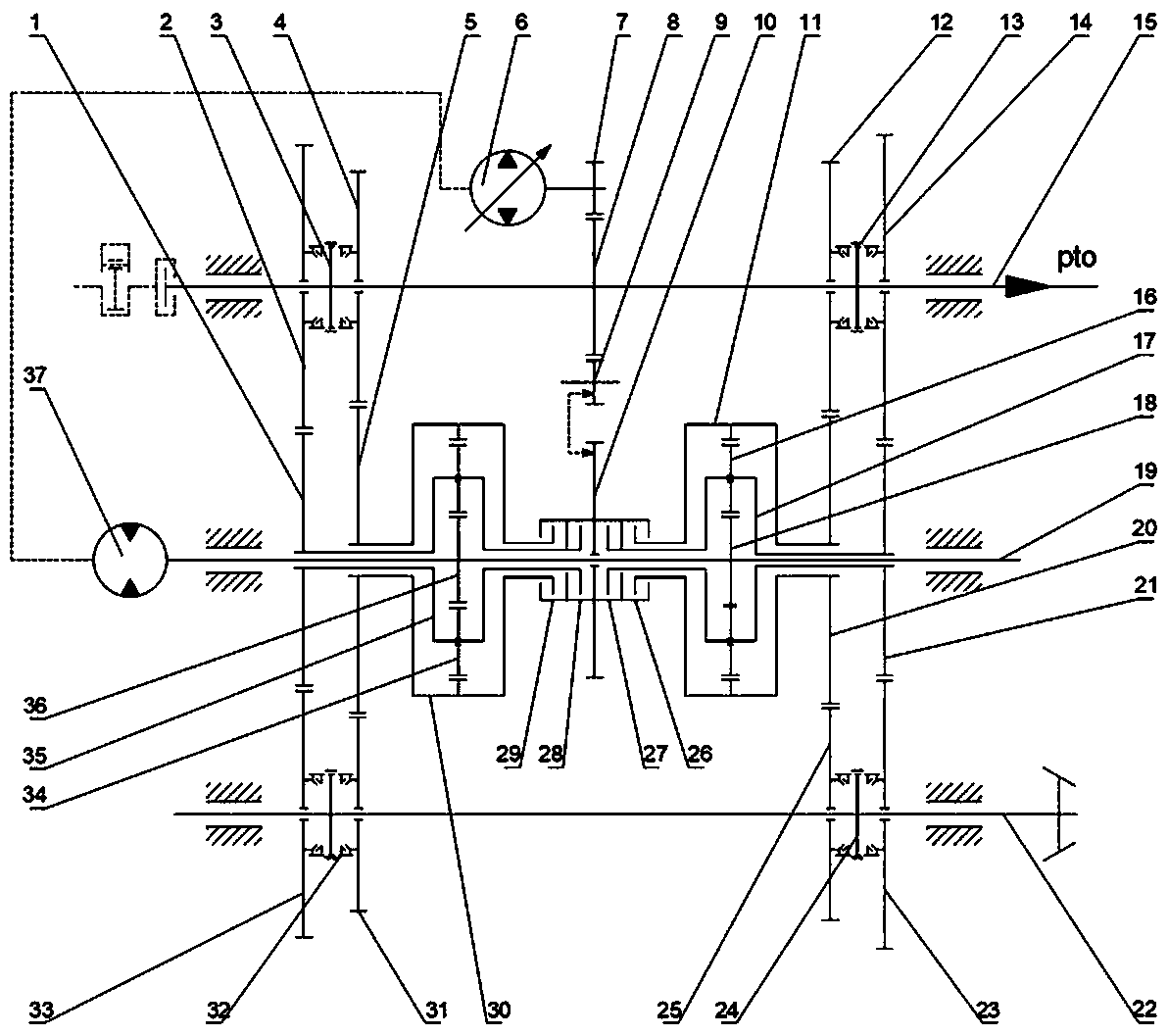

Image

Examples

Embodiment 1

[0026] Embodiment 1, a purely mechanical transmission form M1 gear of a double-planet row multi-stage multi-clutch hydraulic-mechanical continuously variable transmission: as figure 2 As shown, the power transmitted from the engine passes through the first synchronizer 3, the first synchronizer 3 is engaged with the first gear 2, and one path of power is transmitted to the power output device through the input shaft 15; the other path of power passes through the first gear 2, the second gear The second gear 1 and the third gear 33. At this time, the third synchronizer 32 is engaged with the third gear 33, the clutch assembly is completely separated, the front ring gear 30 is in an unconstrained state, and the power is transmitted to the output through the third synchronizer 32. The shaft 22 is finally output to the vehicle traveling device.

[0027] There are also M2, M3, and M4 gears similar to the M1 gear in the purely mechanical transmission form, and will not be described...

Embodiment 2

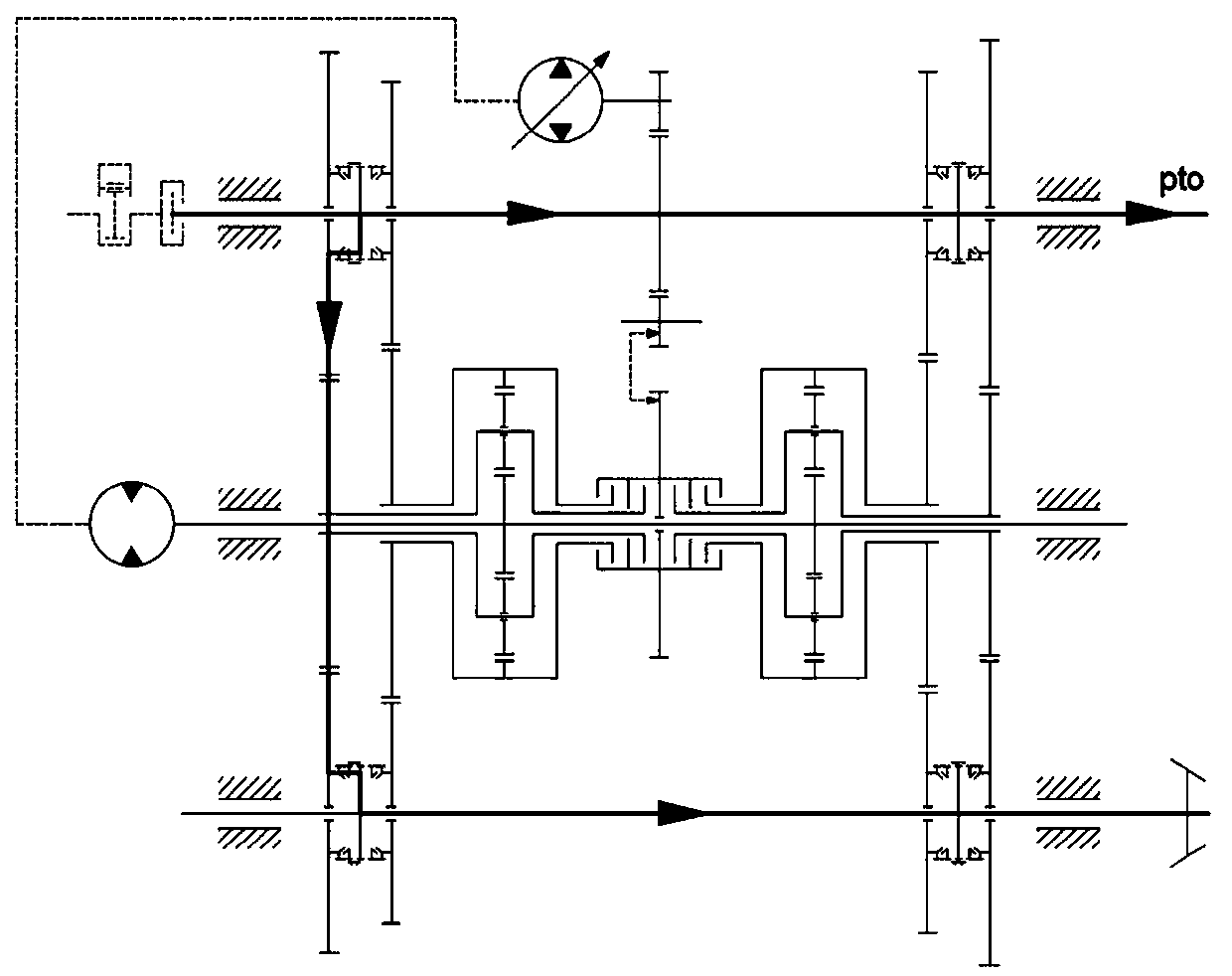

[0028] Embodiment 2, a double planetary row multi-stage multi-clutch hydraulic-mechanical continuously variable transmission in the form of hydraulic-mechanical hybrid transmission in which the front planetary row confluences and outputs the HM1 gear: as image 3 As shown, the power transmitted from the engine passes through the first synchronizer 3, the first synchronizer 3 is engaged with the first gear 2, and the power along the way is transmitted to the hydraulic transmission assembly and the power output device through the input shaft 15 and the seventh gear 8, The power flowing through the hydraulic transmission assembly is finally transmitted to the front sun gear 36 of the front planetary confluence device; the other power is transmitted to the front planet carrier 35 through the first gear 2 and the second gear 1 . The two-way power flows are converging at the front planetary confluence device, and are output from the front ring gear 30 to the fifth gear 5 and the sixt...

Embodiment 3

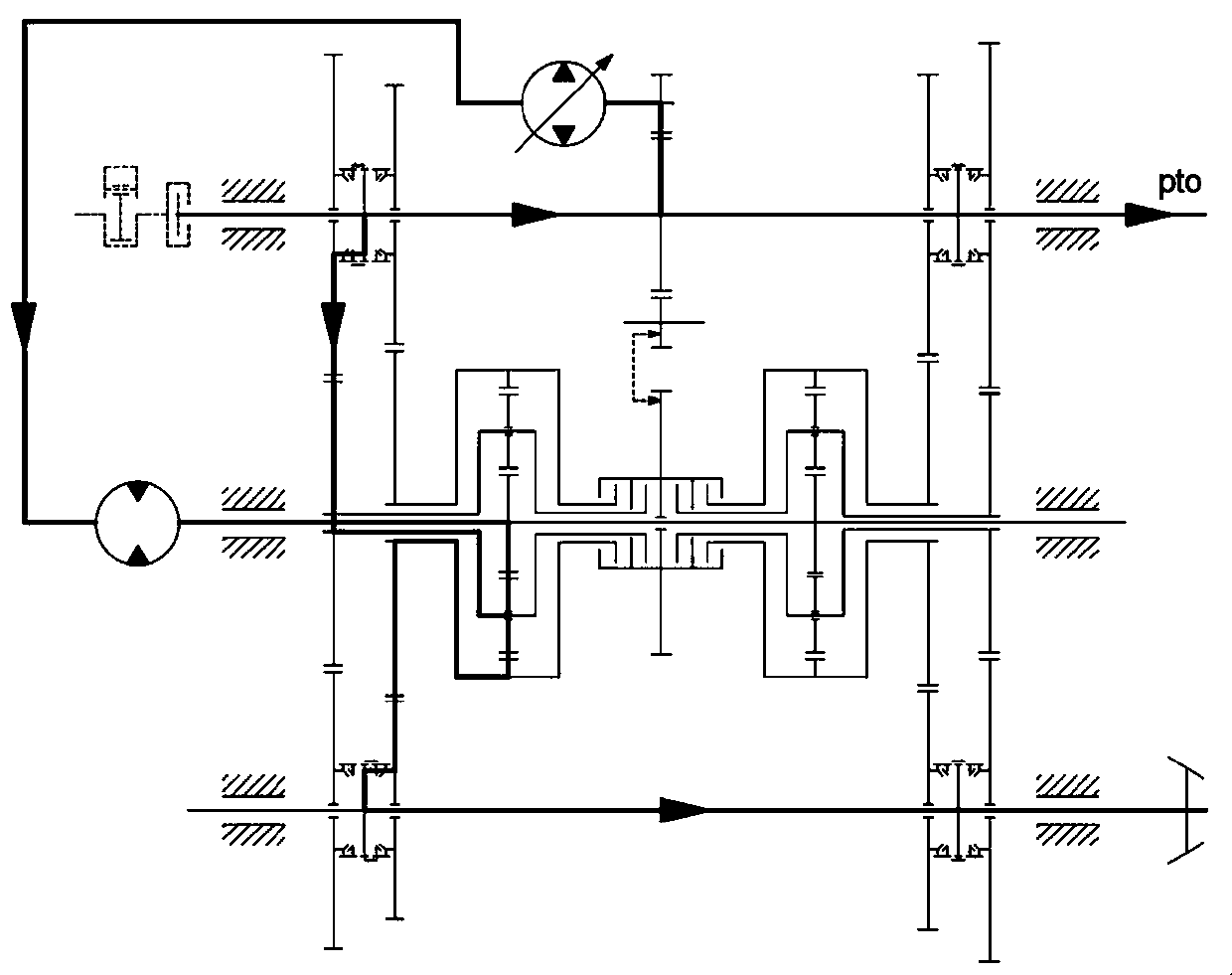

[0030] Embodiment 3, a double-planet row multi-stage multi-clutch hydraulic-mechanical continuously variable transmission in which the front planetary row confluence passes through the rear planetary row output hydraulic-mechanical hybrid transmission HM5 gear: as Figure 4 As shown, the power transmitted from the engine passes through the first synchronizer 3, the first synchronizer 3 is engaged with the first gear 2, and the power along the way is transmitted to the hydraulic transmission assembly and the power output device through the input shaft 15 and the seventh gear 8, The power flowing through the hydraulic transmission assembly is finally transmitted to the front sun gear 36 of the front planetary confluence device; the other power is transmitted to the front planet carrier 35 through the first gear 2 and the second gear 1 . The two-way power flow is confluent at the front planetary row confluence device, and is output from the front ring gear 30 to the clutch assembl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap