Fabricated wallboard and assembly method and disassembly method of fabricated wallboard

A prefabricated, wall panel technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of consuming large hydropower resources, unfavorable energy saving and environmental protection, dust flying, etc., to avoid wall separation, improve stability, and avoid horizontal movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

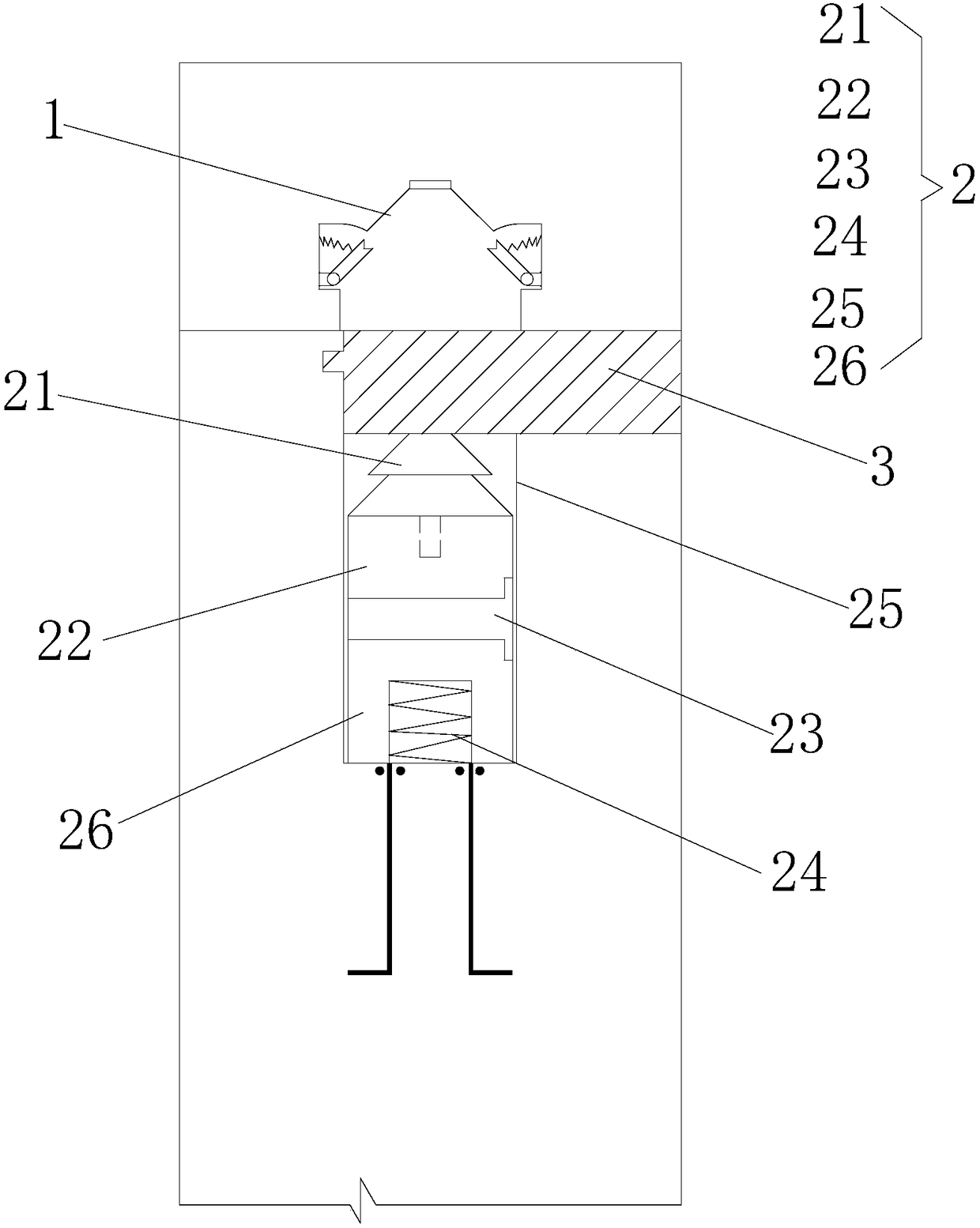

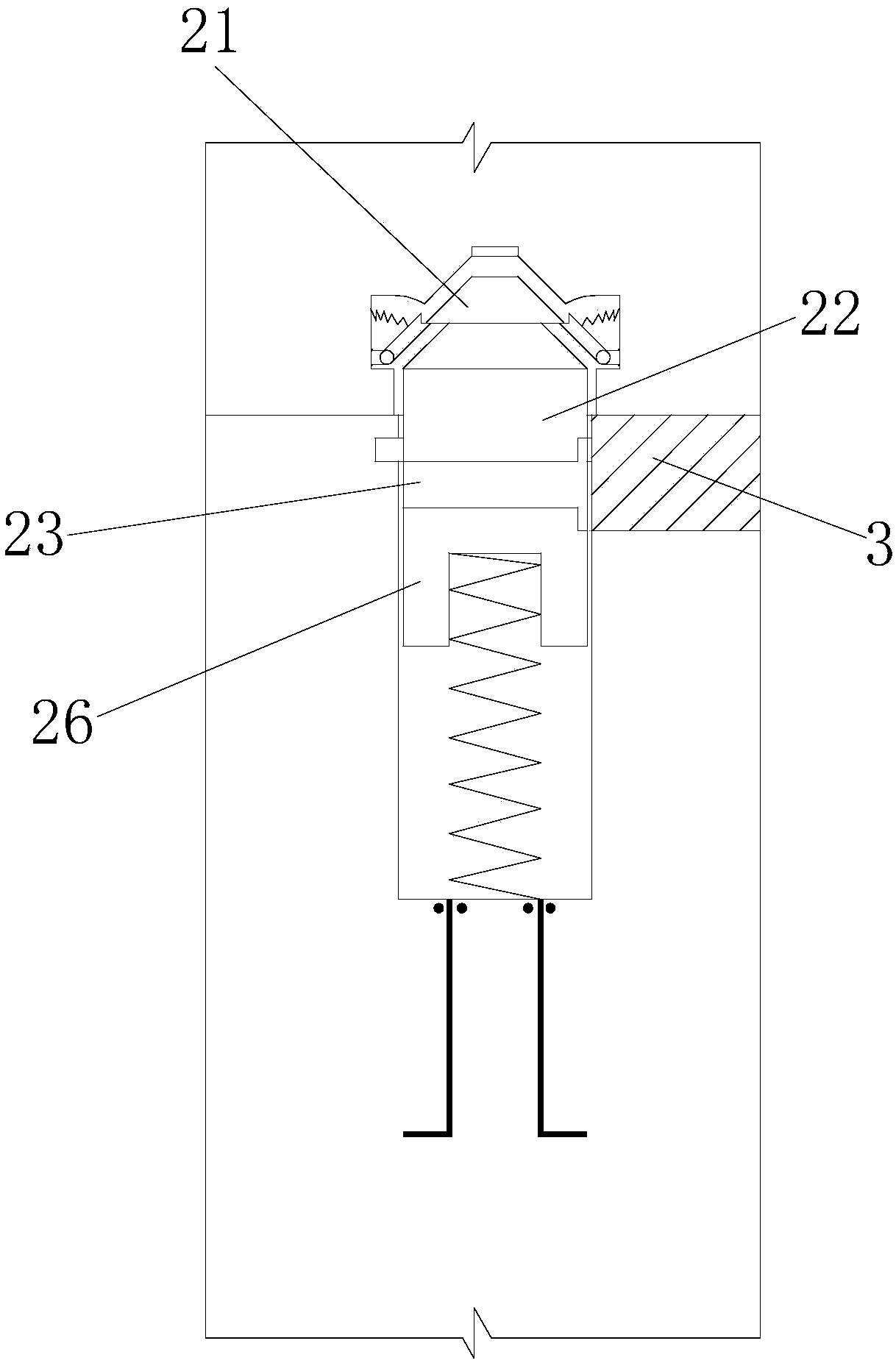

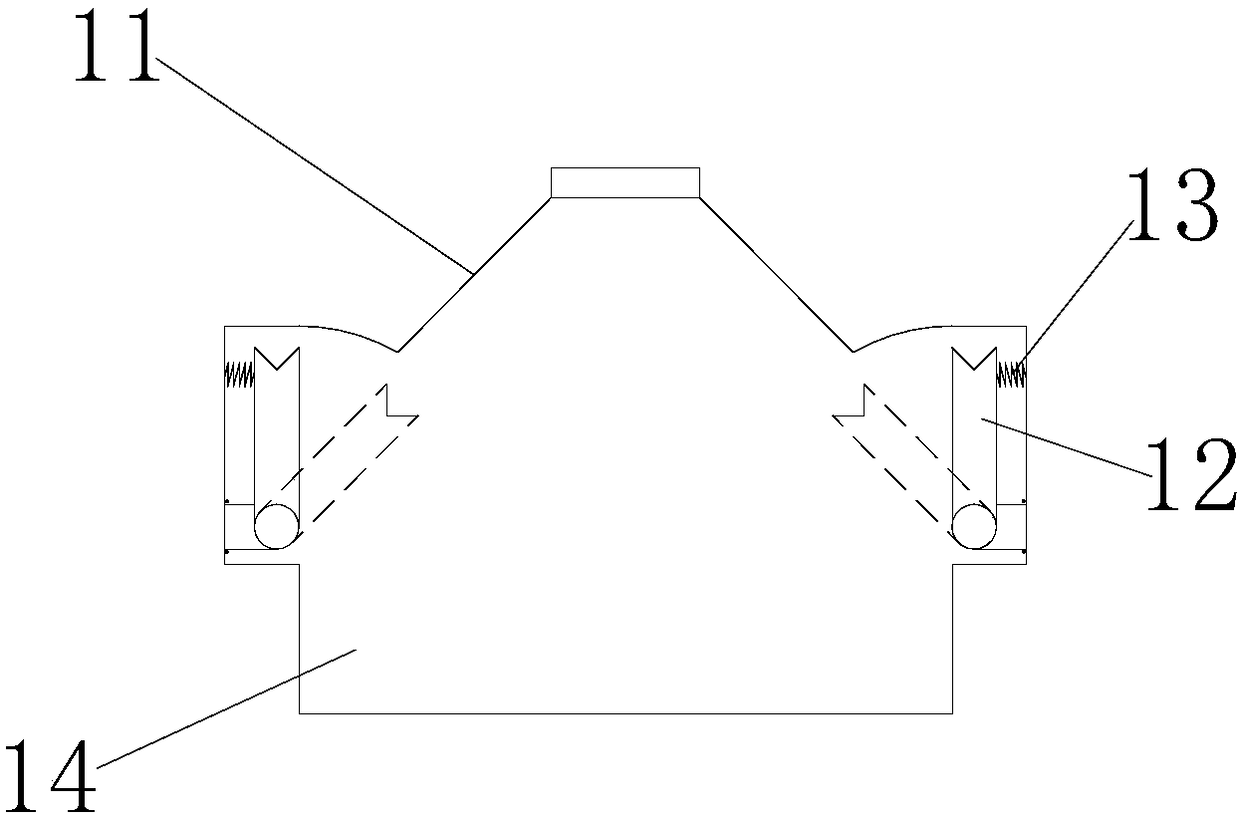

[0034] Such as Figure 1 to Figure 13As shown, a prefabricated wallboard includes a main body of the wallboard. The two sides of the main body of the wallboard are respectively provided with a tenon and a tenon groove along the height direction of the main body of the wallboard. The shape and size of the tenon match the groove; the top of the main body of the wallboard There are pre-embedded wall clips for connecting the beams; the wall clips include a wall clip shell, the lower end of the wall clip shell is a closed end, the upper end is an open end, and a concave hole is opened on one side of the open end. The top surface of the main body of the wall panel has an opening that can expose the open end of the wall clip housing, and the wall facade has a cover channel that communicates with the notch; the wall clip housing is connected from the closed end to the open. In the direction of the end, there are ejection parts, intermediate connecting parts, shear parts and chucks tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com