Swinging cloth collecting machine

A technology of cloth rewinding machine and cloth roll, applied in the field of cloth processing, can solve the problems of cloth damage, irregular folding and tension fluctuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

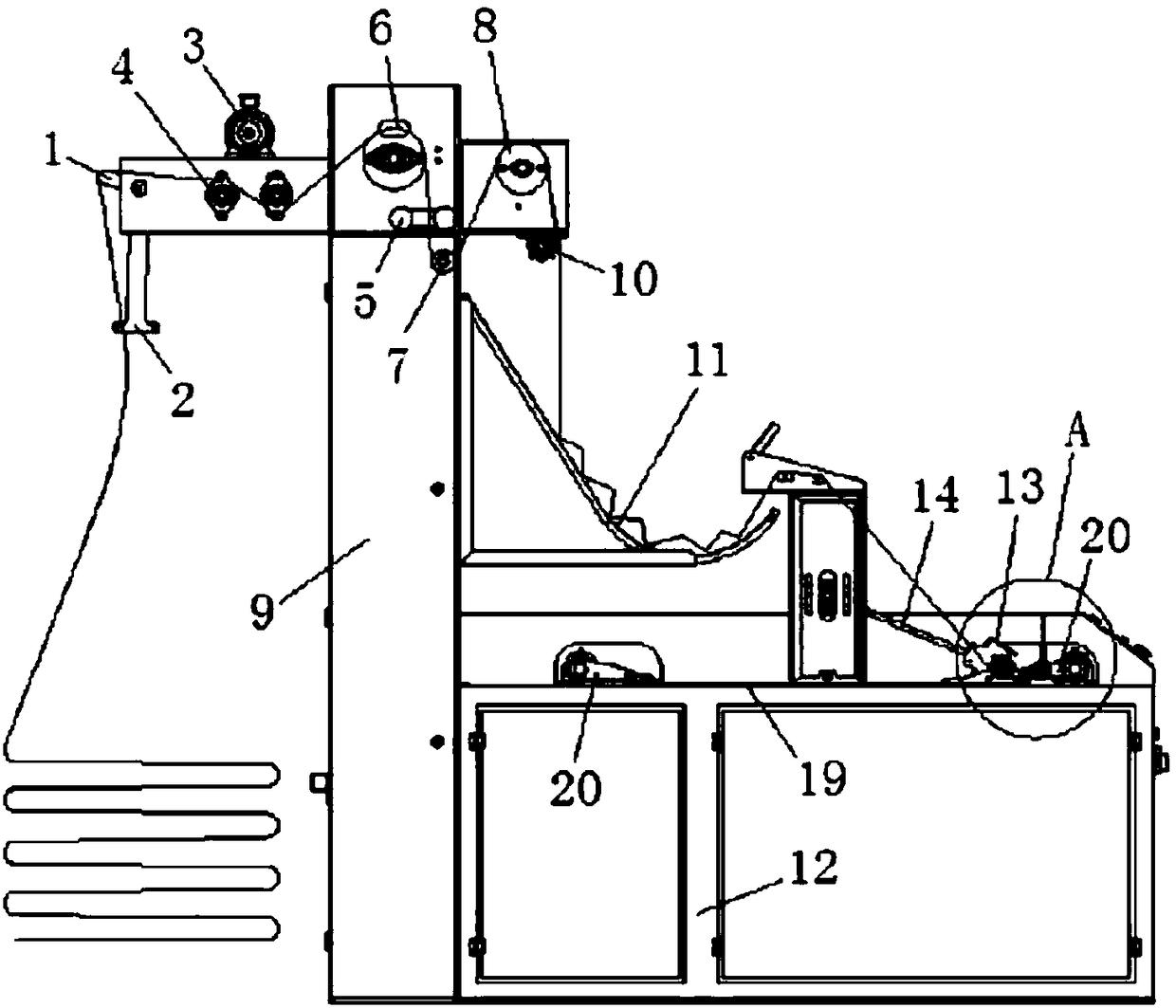

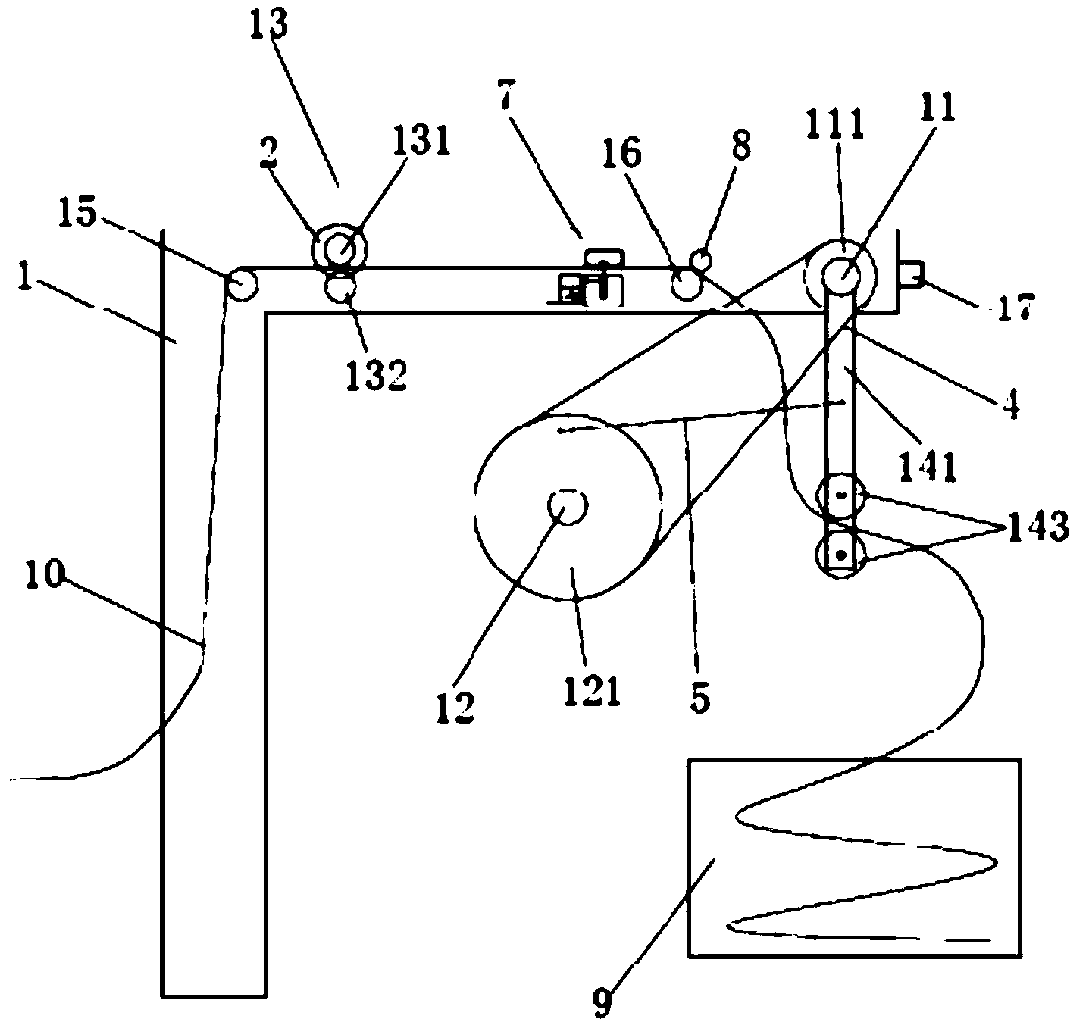

[0022] A swinging cloth machine, such as Figure 4 As shown, it includes a bracket and a swinging cloth winding device arranged on the bracket, the swinging cloth winding device is used for unwinding and folding the cloth roll, and the swinging cloth winding device swings the cloth roll.

[0023]The swinging cloth collecting device includes a first driving pulley 1, a first driving pulley shaft 2, a first connecting rod 3, a first transmission belt 4, a first driven pulley 5, a cloth winding roller 6, a first driven belt Axle 7, triangle transmission plate 8, second link 9, third link 10, fourth link 11, second driven pulley shaft 12, second driven pulley 13, fifth link 14, second The transmission belt 15, the second driving pulley shaft 16, the second driving pulley 17, the cloth feeding roller 18, the first driving pulley shaft 2 is rotatably arranged on the bracket, and the first driving pulley 1 is fixedly arranged on the first driving pulley. On a driving pulley shaft 2 ...

Embodiment 2

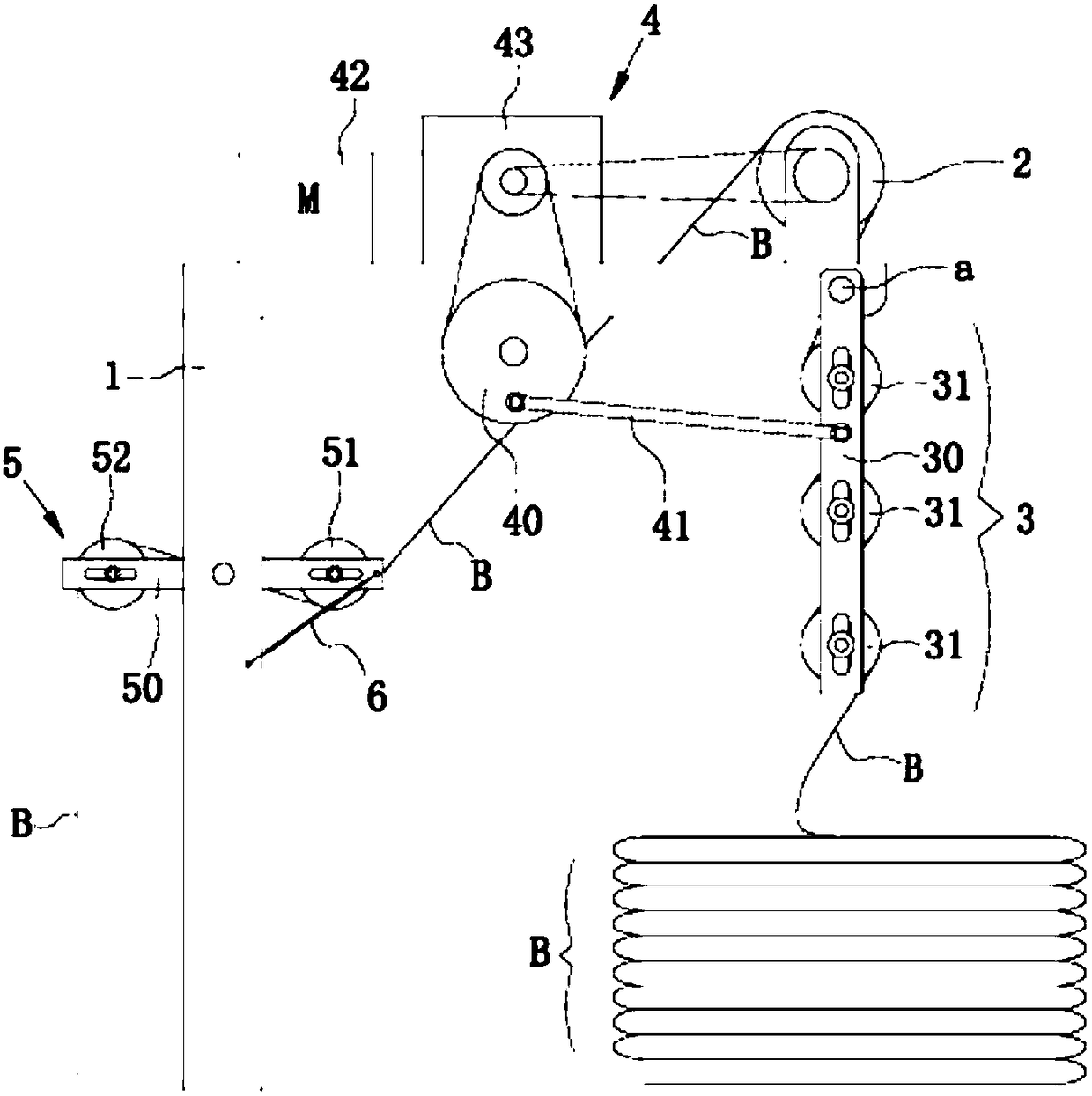

[0029] A swinging cloth machine, such as Figure 5 As shown, it includes a bracket and a swinging cloth winding device arranged on the bracket, the swinging cloth winding device is used for unwinding and folding the cloth roll, and the swinging cloth winding device swings the cloth roll.

[0030] The swinging cloth collecting device includes a first driving pulley 1, a first driving pulley shaft 2, a first connecting rod 3, a first transmission belt 4, a first driven pulley 5, a cloth winding roller 6, a first driven belt Axle 7, triangle transmission plate 8, second link 9, third link 10, fourth link 11, second driven pulley shaft 12, second driven pulley 13, fifth link 14, second The drive belt 15, the second drive pulley shaft 16, the second drive pulley 17, the cloth feed roller 18 and the fourth drive belt 19, the first drive pulley shaft 2 is rotatably arranged on the bracket, and the first drive pulley 1 is fixed It is arranged on the first driving pulley shaft 2, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com