Wheel assembly

A technology of wheel components and gear sets, which is applied in the direction of wheels, vehicle parts, wheel hubs, etc., and can solve problems such as slight shaking and obvious shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

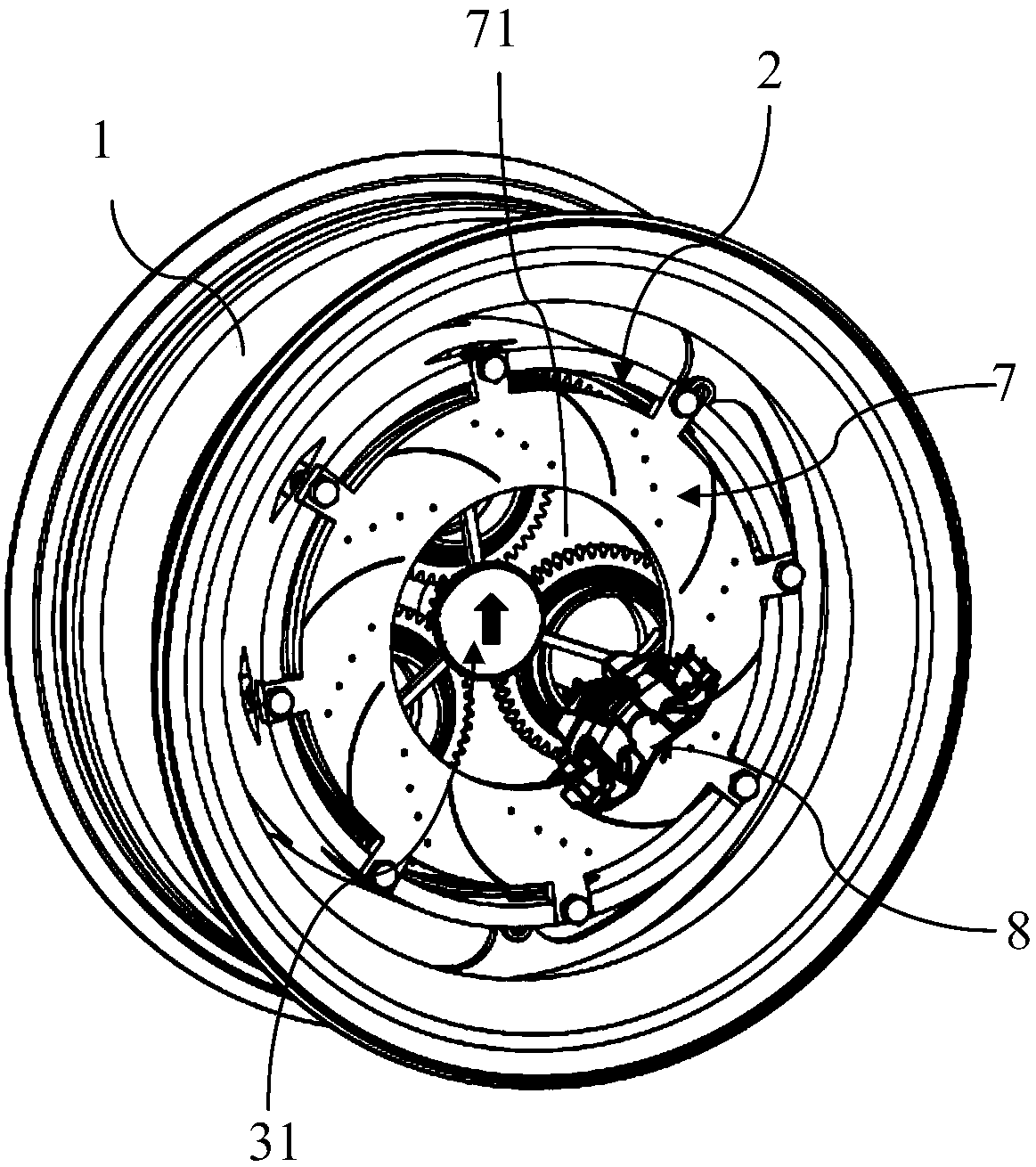

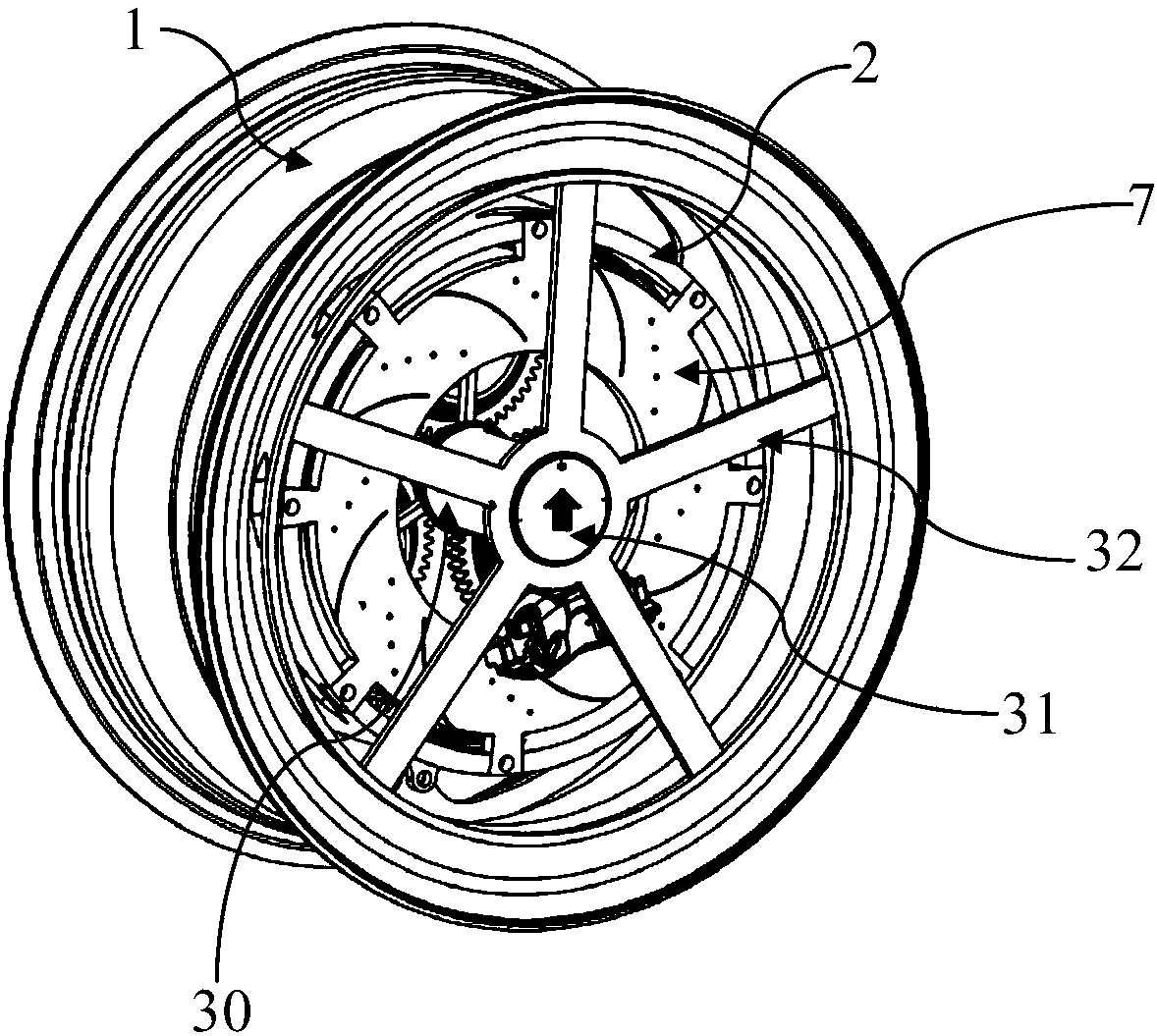

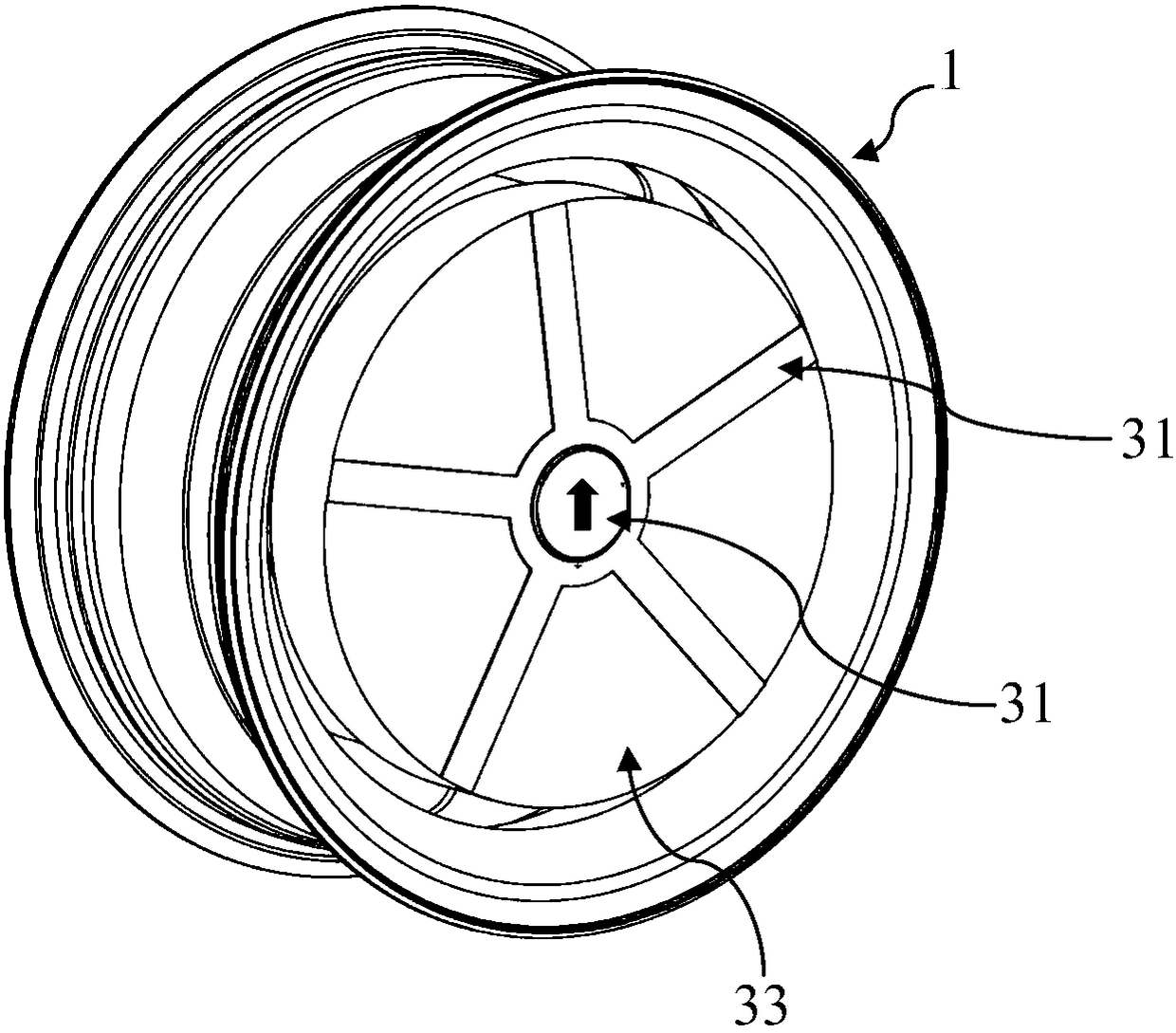

[0041] Such as Figure 1-9 and Figure 11-13 As shown, a wheel assembly provided by an embodiment of the present invention includes a rim 1 , a rotating outer hub 2 , a non-rotating inner hub 3 and a car logo 31 fixedly installed on the inner hub 3 .

[0042] A support seat 4 and an inner ball cage 5 are also provided in the outer hub 2, the inner ball cage 5 passes through the support seat 4, the support seat 4 is installed in the outer wheel hub 2 through a support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com