A kind of jade processing technology

A processing technology and jade technology, applied in the field of jade processing technology, can solve the problems of inability to adjust the depth of cutting, low work efficiency, large axial jitter of the blade, etc., so as to improve the dewaxing work efficiency, improve work efficiency, and ensure rotation. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0045] A kind of jade processing technology, comprising,

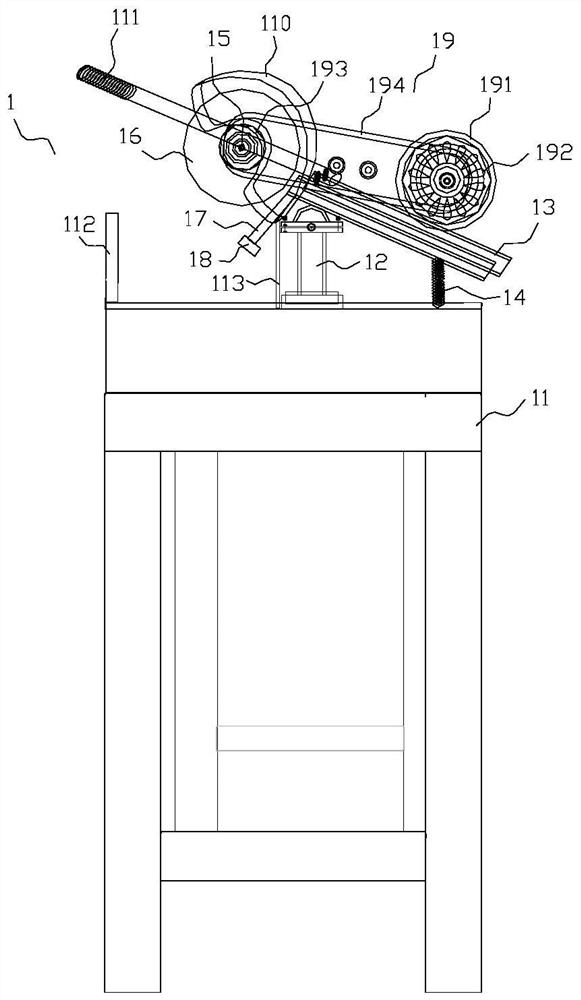

[0046] Steps of material selection: use a jade cutting machine to cut the rough stone, select the jade material, and then cut the jade raw material into the corresponding shape and size;

[0047] Drawing steps: according to the color and cracks, draw the pattern on the surface of the jade;

[0048] Sampling steps: use a jade shaping machine for rough processing according to the drawn pattern, and repair a shape similar to the pattern;

[0049] Steps of fine repair: use engraving flat machine to modify and process the details of the jade pattern;

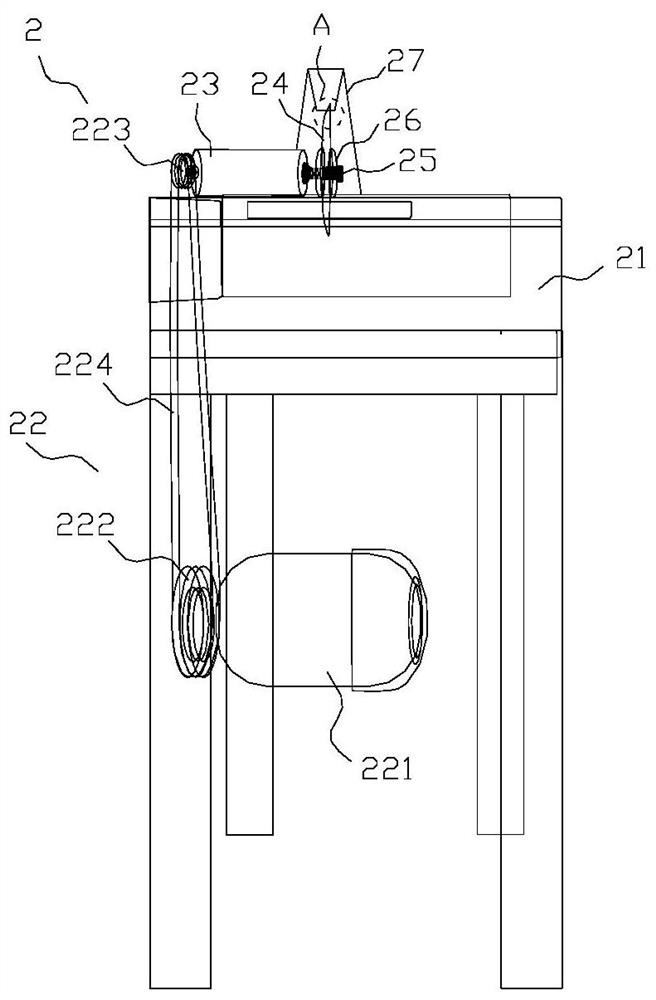

[0050] Polishing steps: Then use a polishing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com