Device and method for adjusting angle of upper row chain of tobacco cutting machine

An angle adjustment device and shredding machine technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of upper chain transmission speed, compression ratio change, difficult adjustment of upper chain mechanical structure, limited adjustable range, etc. problem, to achieve the effect of wide adjustable angle range, simple structure and large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

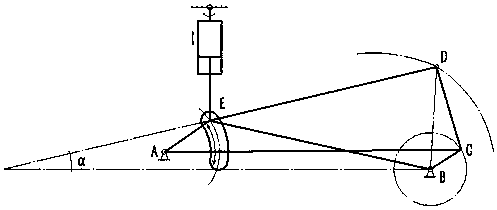

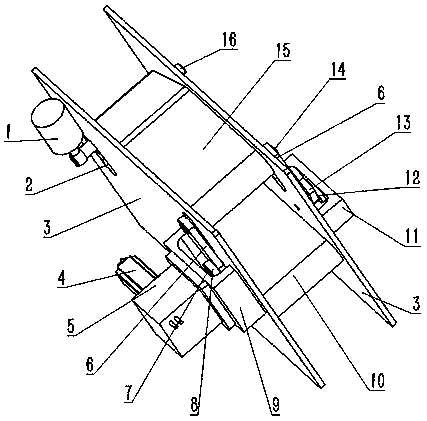

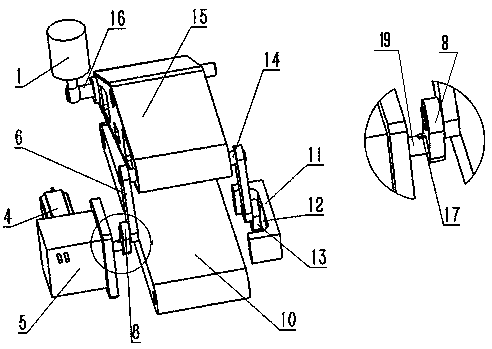

[0030]Tobacco shredding machine upper chain angle adjustment device, left and right wall panels 3 are provided with upper chain 15 and lower chain 10, front axle and rear axle are provided with upper chain, limit groove 2 is provided in front of the wall panel, and front end A front axle 16 with a clearance fit is arranged in the limit groove, and a cylinder 1 is provided at the left end of the front axle; a rear axle 14 with a clearance fit is arranged on the limit groove at the rear end of the wallboard, and a swing arm 6 is provided with a clearance fit at both ends of the rear axle. , the other end of the left side swing arm is rotatably connected to the adjustment arm 8 by the bearing, the other end of the adjustment arm is fixedly connected to the indexing device 5 through the key 17, the indexing device is connected with the servo motor 4, and the servo motor is installed on the motor support 9, The other end of the right swing arm is rotatably connected to the driven ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com