Mechanical iron residue removal device used for livestock and poultry feed processing

A feed processing and iron slag removal technology, applied in feed, application, magnetic separation, etc., can solve the problems that feed cannot be stored for too long, is difficult to store for too long, and does not have dry feed, so as to avoid feed temperature. High, increase the storage time, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

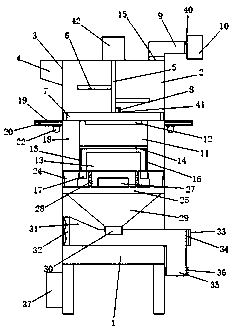

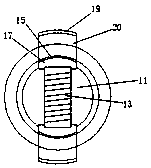

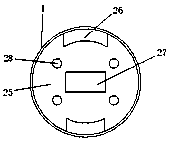

[0020] Such as Figure 1-Figure 5As shown, an iron and slag removal device for livestock feed processing machinery includes a housing 1, the inner cavity of the housing 1 is provided with a feeding bin 2, and the left side of the feeding bin 2 is provided with a feeding port 3 , one side of the feed port 3 is provided with a feed hopper 4, the inner cavity of the feed bin 2 is provided with a stirring shaft 5, and the outside of the stirring shaft 5 is provided with a stirring rod 6, and the bottom end of the stirring rod 6 is fixed A scraper 7 is installed, which can fully stir the feed, make the feed evenly heated, accelerate the drying of the feed, and at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com