Sausage filling device

A filling device and sausage technology, applied in the field of food processing, can solve the problems of rolling back and forth, difficult positioning, etc., and achieve the effect of obvious application effect and saving equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

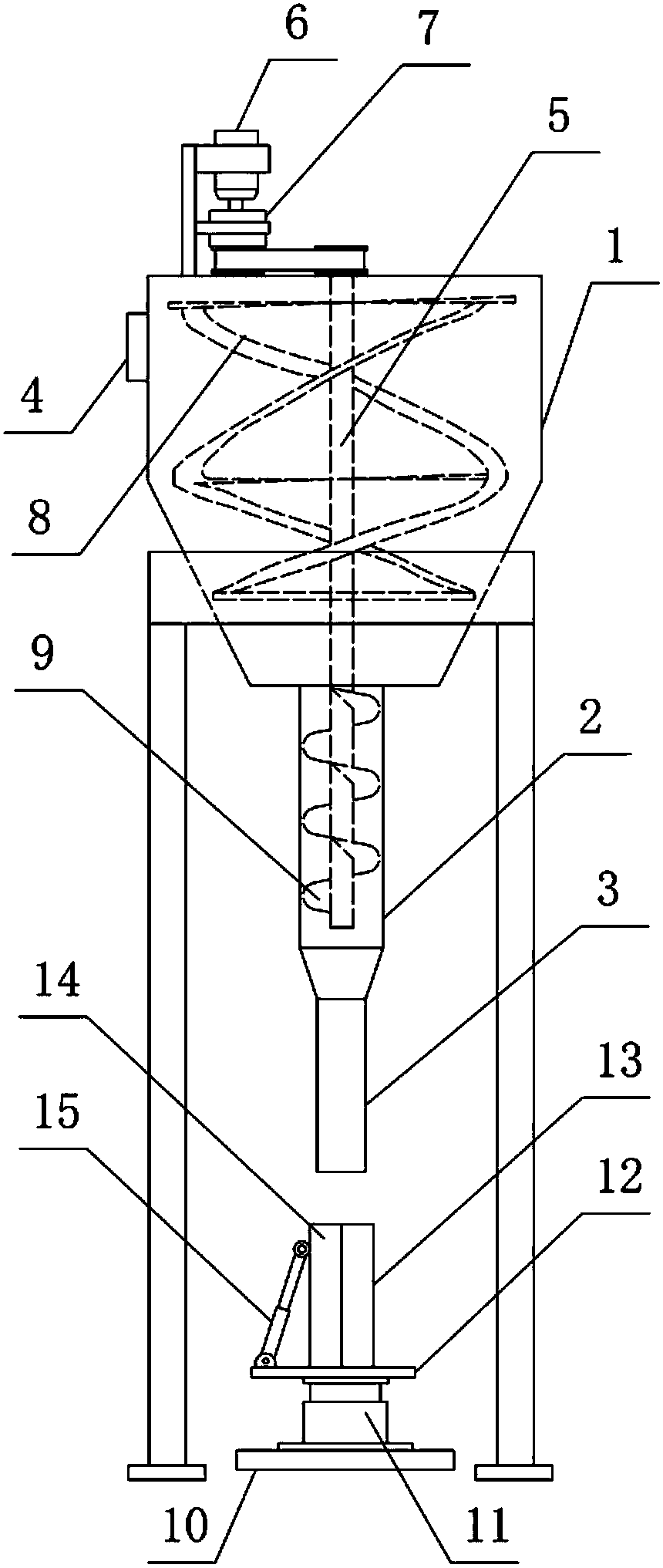

[0028] like Figure 1 to Figure 3 As shown, the present invention includes a stirring and filling mechanism and a supporting mechanism,

[0029] The stirring and filling structure includes, from top to bottom, a stirring shell 1, a filling shell 2, a frustoconical transition pipe 20 and a feeding pipe 3 that are fixedly connected and communicated in sequence. The side wall of the stirring shell 1 is provided with a feeding port 4, and the The top is provided with a rotating shaft 5 in a vertical direction, a motor 6 and a reducer 7 are arranged on the outer side of the top of the stirring shell 1, the output shaft of the motor 6 is connected with the input shaft of the reducer 7, and the upper end of the rotating shaft 5 extends into the outer side of the stirring shell 1 It is connected with the output shaft of the reducer 7 through a belt drive. The part of the rotating shaft 5 located in the stirring and filling mechanism has a plurality of screw-type stirring paddles 8 and...

Embodiment 2

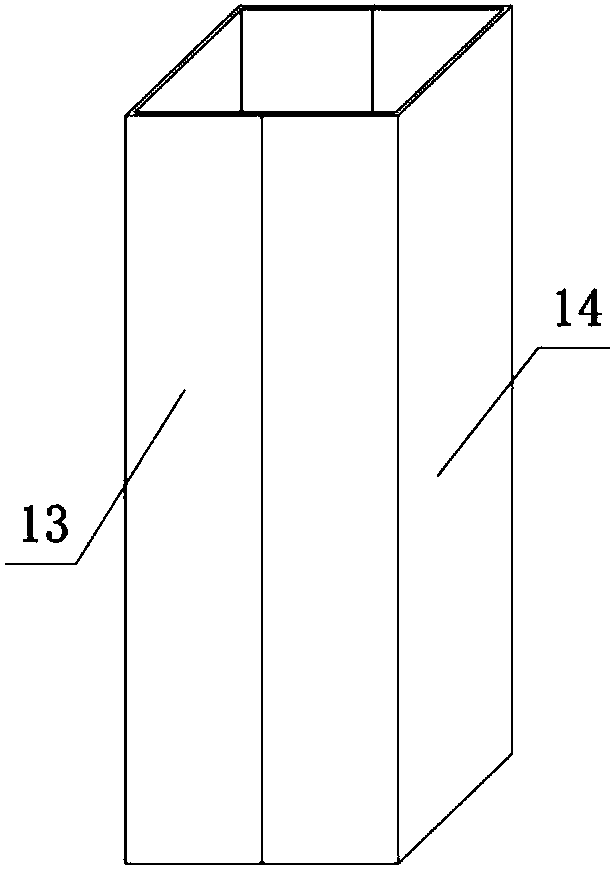

[0034] The structure of this embodiment is basically the same as that of the first embodiment, the difference is: Figure 5 As shown, the first template 13 is provided with a through hole and a push-up mechanism, the push-up mechanism includes a push rod, a spring 16 and a fixed seat 17, and the push rod includes a first push rod 18 and a second push rod 19 that are integrally formed. The ejector rod 18 is slidably arranged in the through hole, the spring 16 is sleeved on the outer wall of the first ejector rod 18, the outer diameter of the first ejector rod 18, the outer diameter of the spring 16, and the outer diameter of the second ejector rod 19 increase in sequence, and the spring 16 The two ends of the spring 16 are respectively in contact with the outer wall of the first template 13 and the second ejector rod 19 , the spring 16 is located in the fixed seat 17 , and the end of the second ejector rod 19 away from the first ejector rod 18 extends out of the fixed seat 17 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com