A universal light strip pin

A general-purpose, pin-in technology, applied in the direction of coupling devices, contact parts, electrical components, etc., can solve the problem of uneven spacing of wire tubes, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

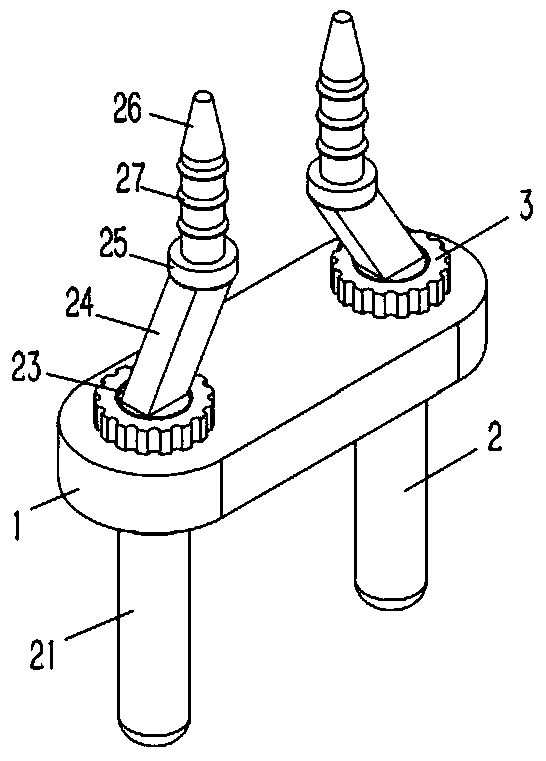

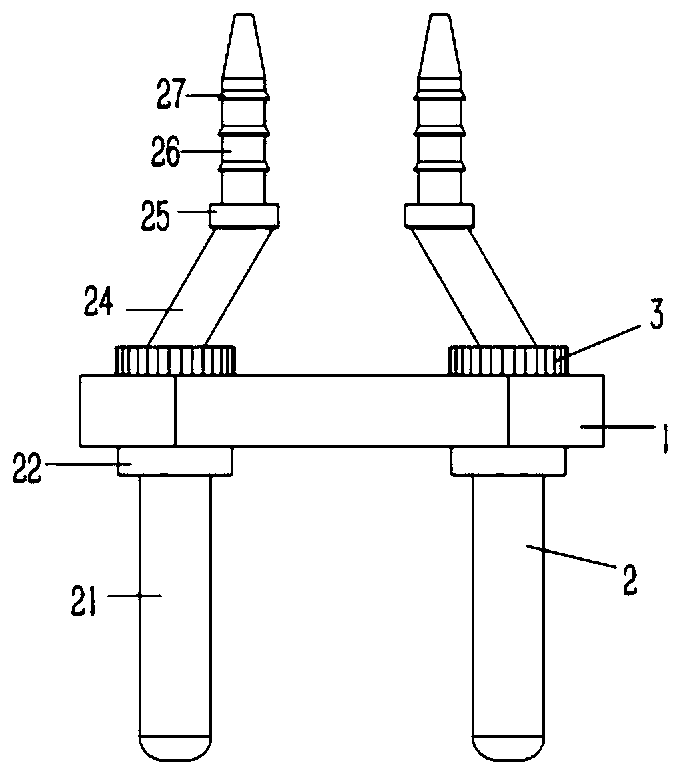

[0015] Example: see figure 1 , 2 As shown, a general-purpose light strip pin includes a plastic connection block 1 and a pin 2. Both ends of the plastic connection block 1 are provided with a pin 2. The pin 2 includes an electrode column 21, and the upper end of the electrode column 21 is formed There is a baffle plate 22, the upper end of the baffle plate 22 is formed with a stud 23, the upper end of the stud 23 passes through the plastic connecting block 1 and is screwed with a screw sleeve 3, and the top of the stud 23 is formed with an inclined strut 24, the strut 24 A circular bump 25 is molded on the top of the bump 25, and a sharp needle 26 is molded on the upper end surface of the bump 25.

[0016] Preferably, two ends of the plastic connecting block 1 are formed with sockets for studs 23 , and the sockets of the plastic connecting block 1 are equal to the diameter of the studs 23 .

[0017] Preferably, the length of the stud 23 on the pin 2 is greater than the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com