Extrusion die seat heating unit

A heating device and mold base technology, applied in the field of heating devices, can solve problems such as poor metal fluidity, uneven product size and performance, and achieve uniform performance, good heating effect, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

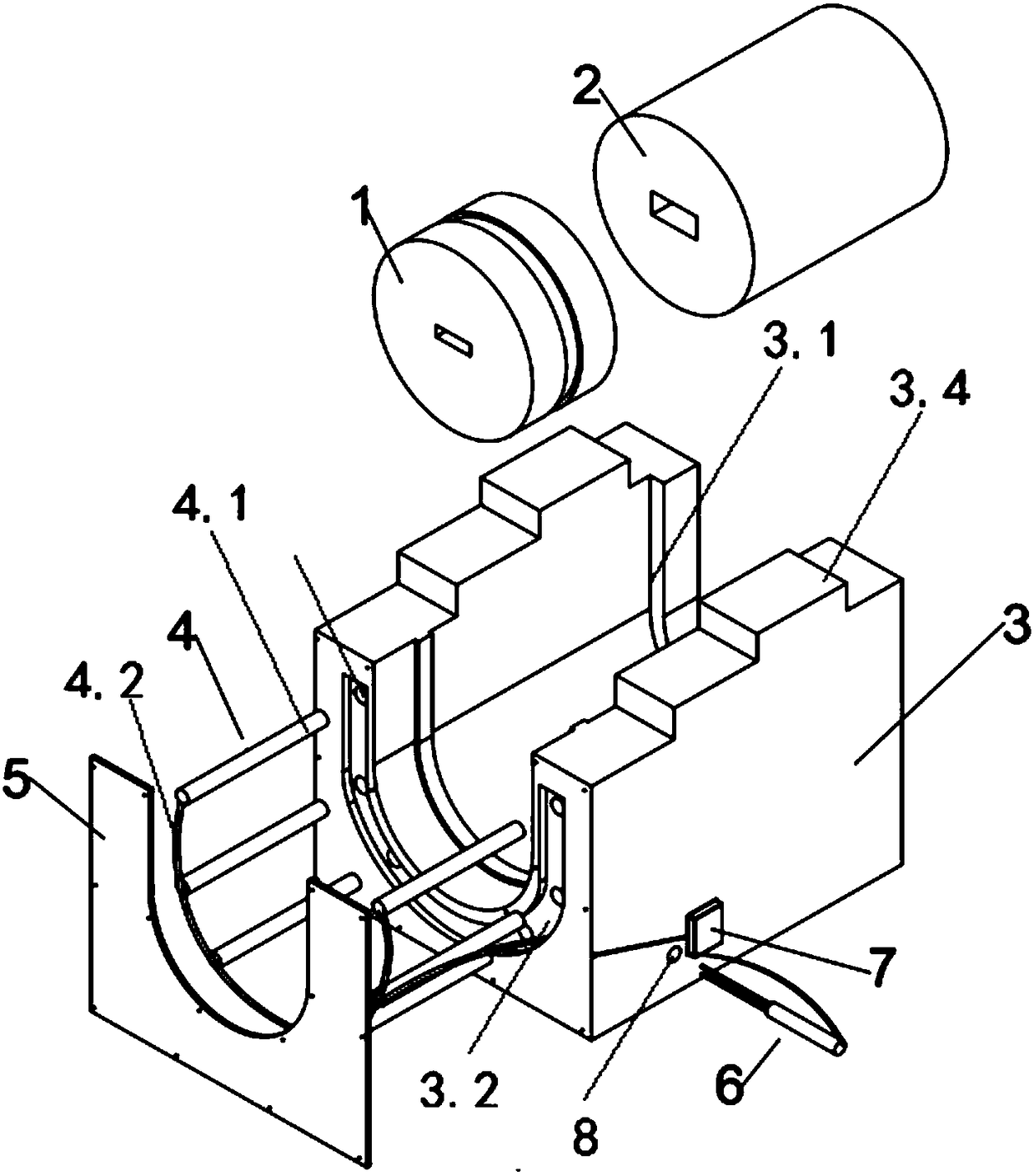

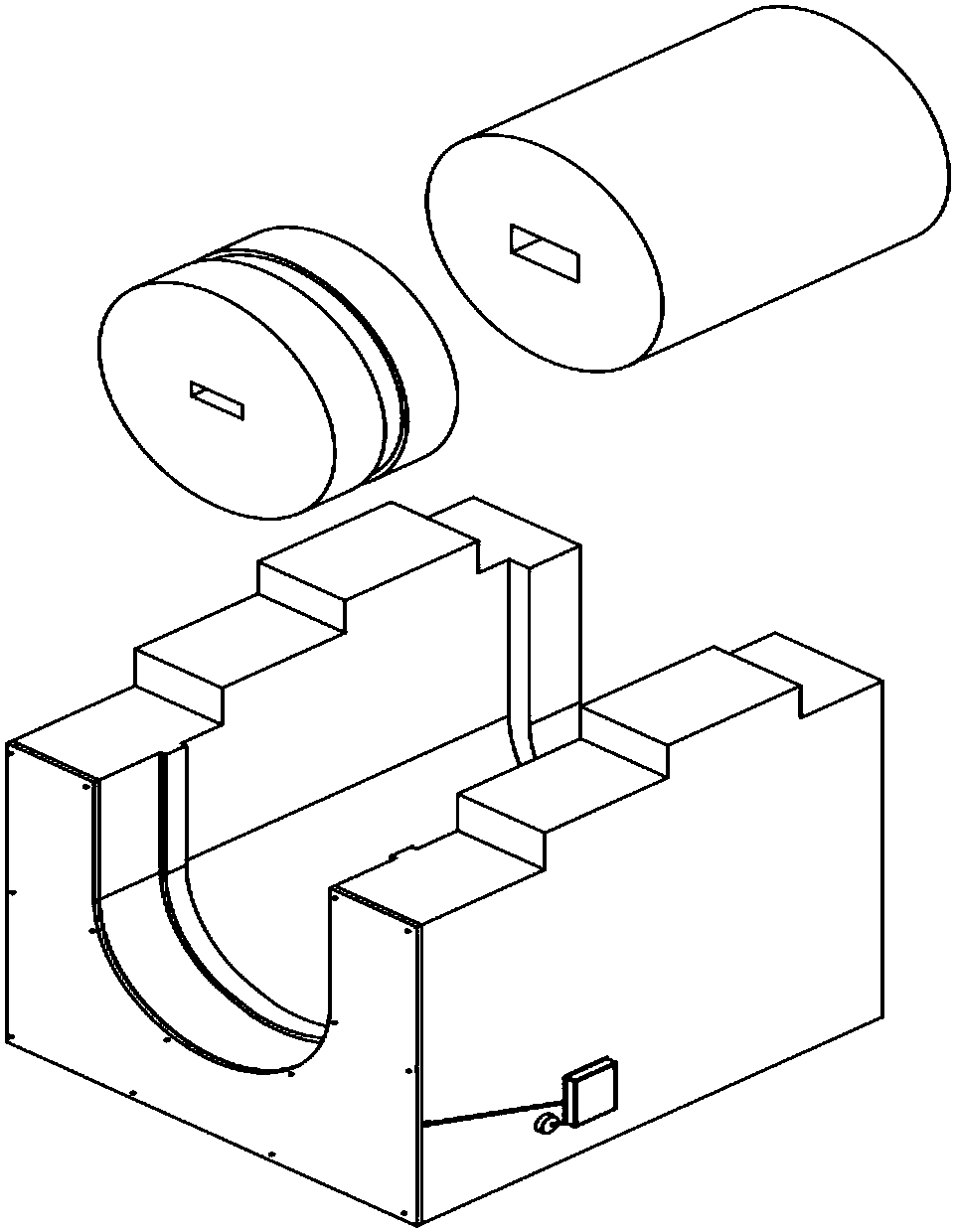

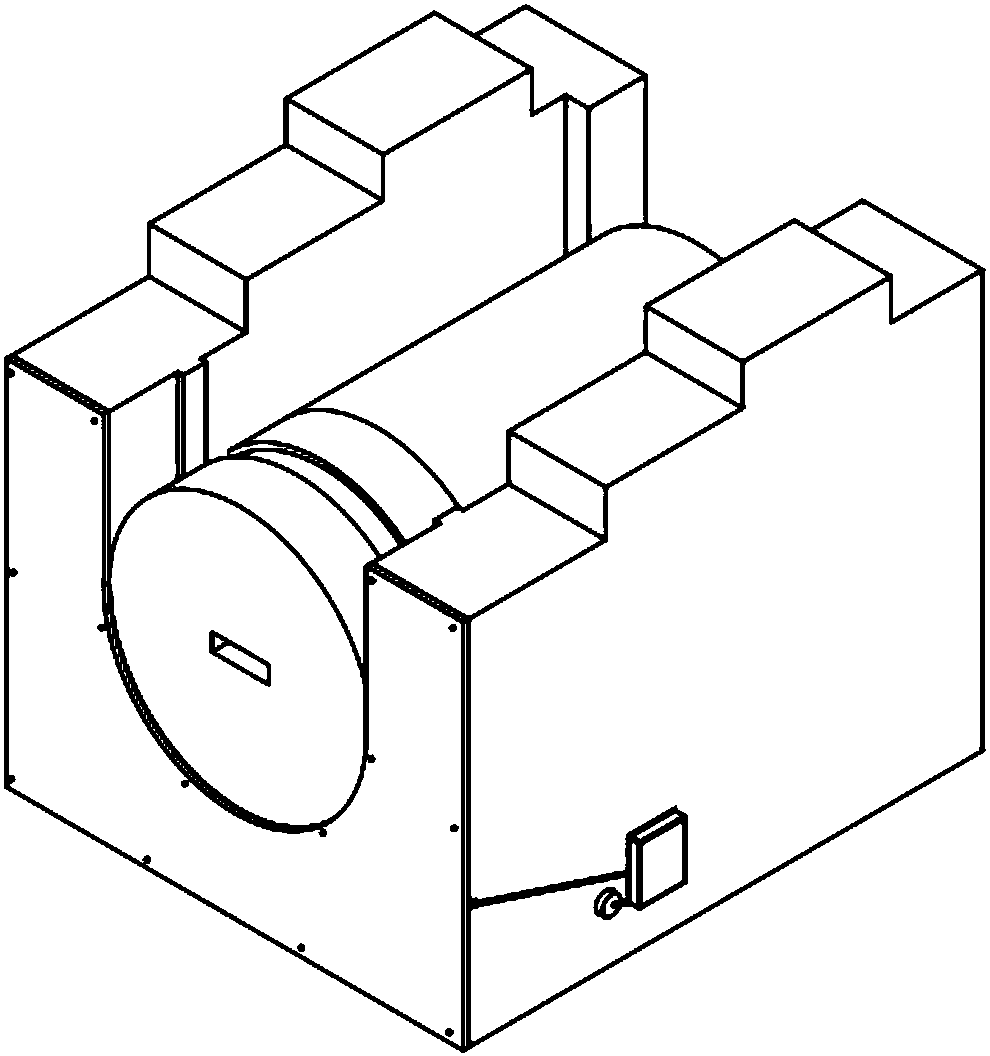

[0023] like Figure 1-3 Shown: a kind of extruding mold seat heating device, it is characterized in that,

[0024] The heating device includes a mold base 3, a temperature controller 7, a thermocouple 6, a heating element 4, and a cover plate 5;

[0025] The mold base has a structure with an open upper end, and a stepped U-shaped through groove 3.1 is opened in the middle, and the mold 1 and the mold pad 2 are matched and placed in the U-shaped groove 3.1. The mold is placed on the front end of the mold pad and passed through the mold. Pad support; another U-shaped groove 3.2 is provided on the front surface of the mold base, and an assembly hole 3.3 for inserting a heating element 4 is arranged in the U-shaped groove, and the heating element includes a plurality of heating rods 4.1 and a plurality of Wires 4.2 for heating rod connection,

[0026] The wire i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com