Coffee processing method, control device and coffee machine

A processing method and technology for a coffee machine, which are applied in the fields of control devices, coffee machines, and coffee processing methods, can solve the problems of inability to meet the fast pace, affect the taste of coffee, and take a long time, so as to improve the degree of automation and use efficiency, and avoid continuous boiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

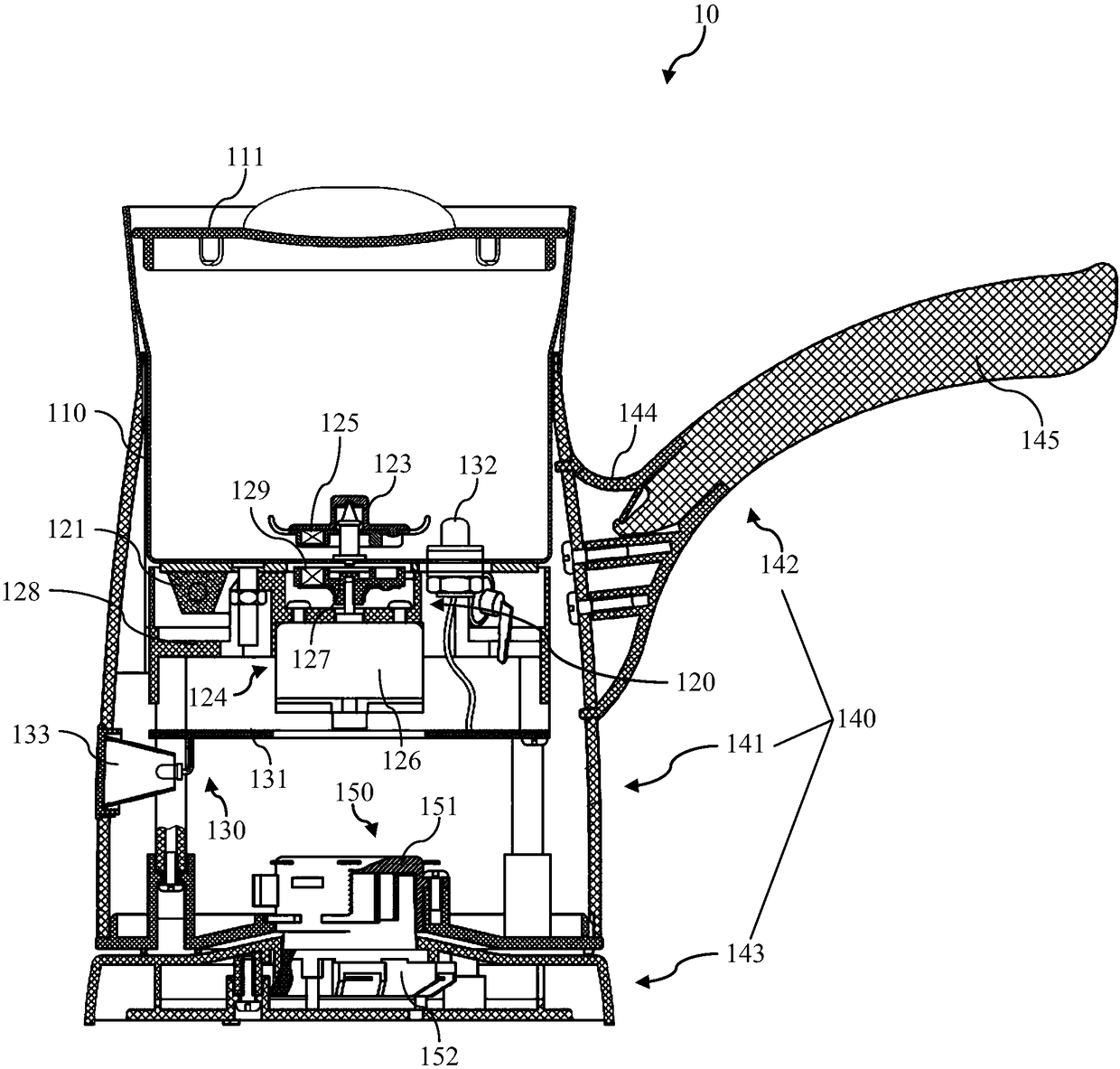

[0020] This article will describe the exemplary embodiments of the present invention in detail with reference to the accompanying drawings. It is understandable that the description of the exemplary embodiments herein should be considered as an example of a coffee processing method and a coffee machine, and is not intended to limit the present invention. 于exemplary implementation.

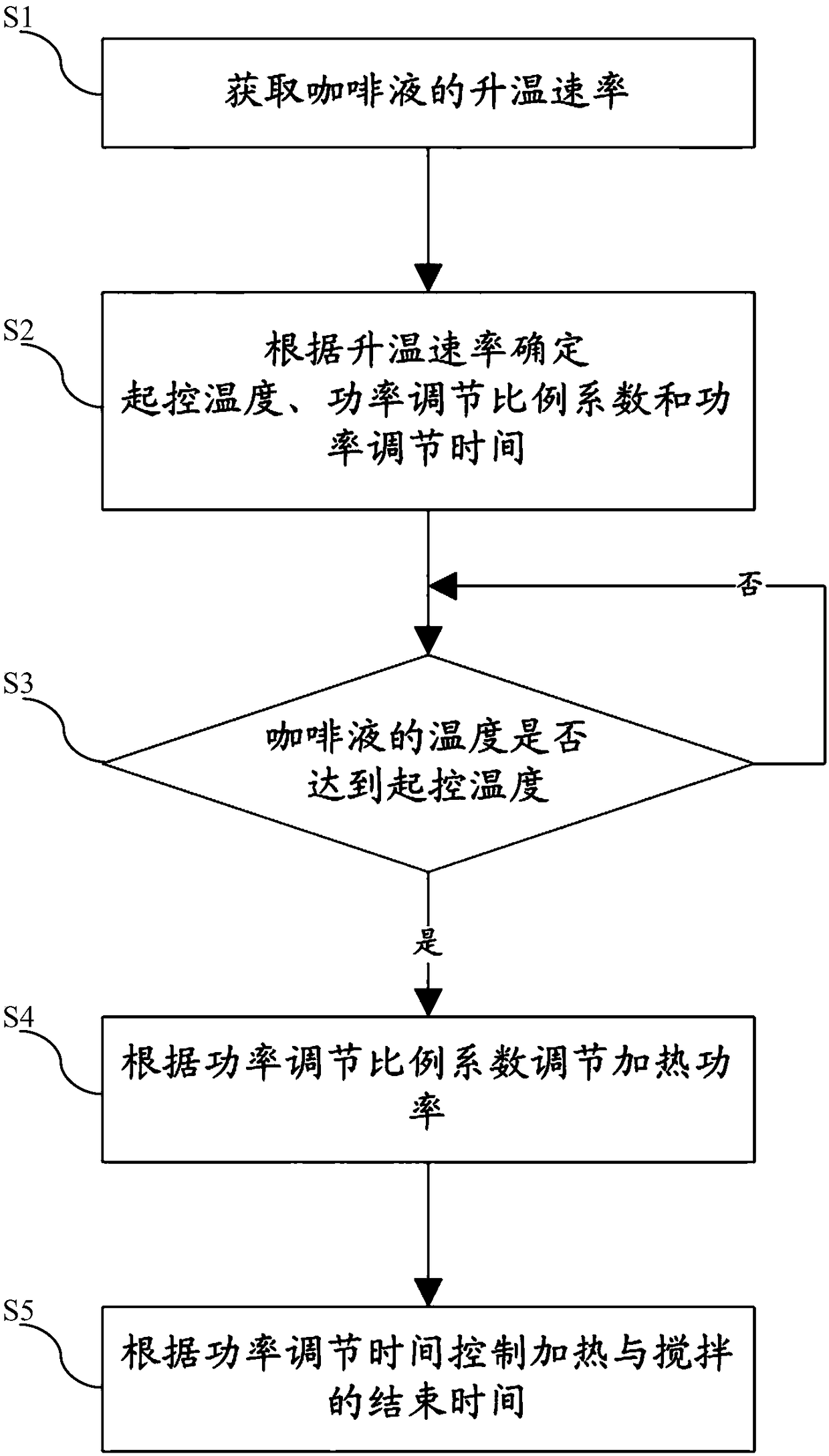

[0021] The embodiment of the present invention provides a coffee processing method, which includes:

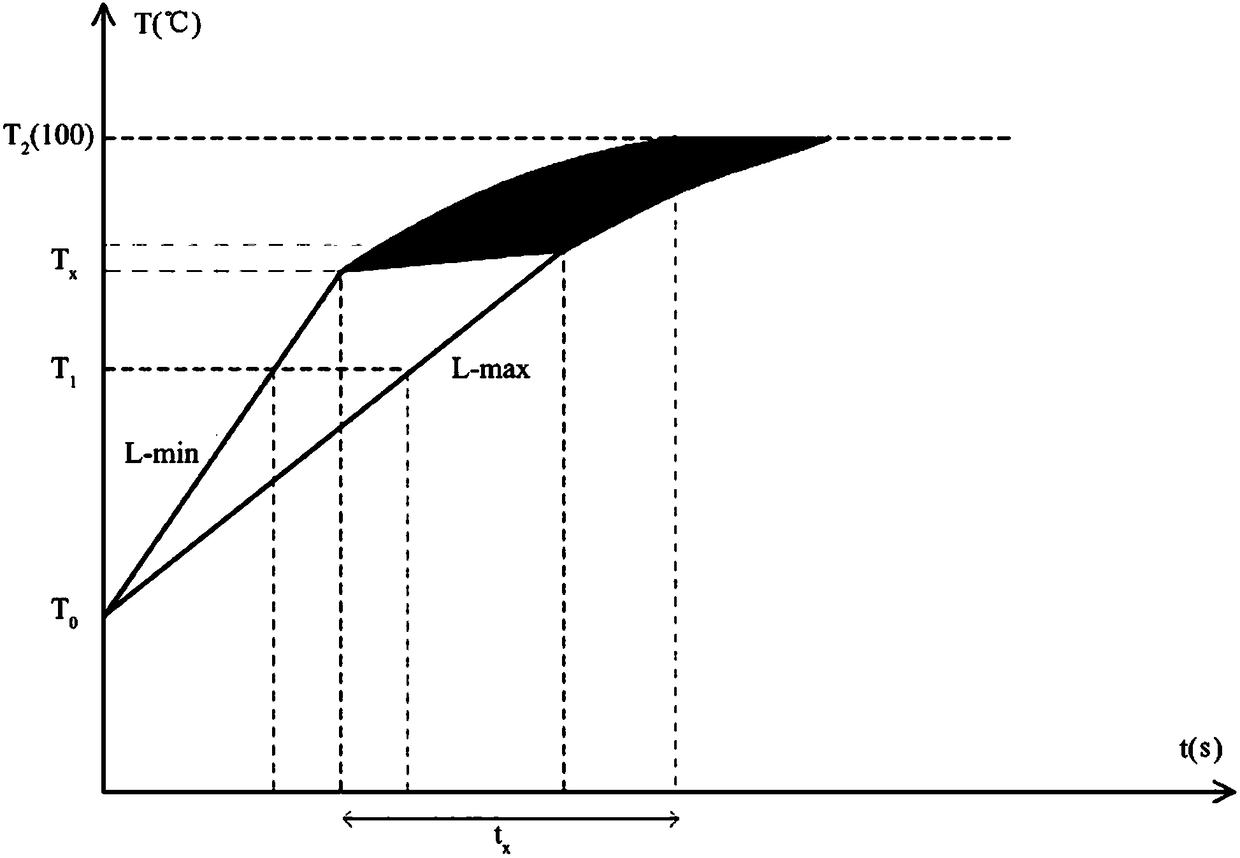

[0022] Determine the heating rate of the coffee liquid in the first working mode of the coffee machine;

[0023] Determine the starting temperature, power adjustment proportional coefficient and power adjustment time according to the heating rate;

[0024] After the temperature of the coffee liquid reaches the starting temperature, the second working mode of the coffee machine is executed according to the power adjustment proportional coefficient and the power adjustment time, which is different from the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com