Tree barrier cleaning air robot and method for telescopic and longitudinally curved working arm

An aerial robot and longitudinal bending technology, applied in agricultural machinery and implements, botanical equipment and methods, agriculture, etc., can solve the problems of low manual cleaning efficiency and high safety risks, so as to facilitate project realization and improve cleaning efficiency , Convenient and quick adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

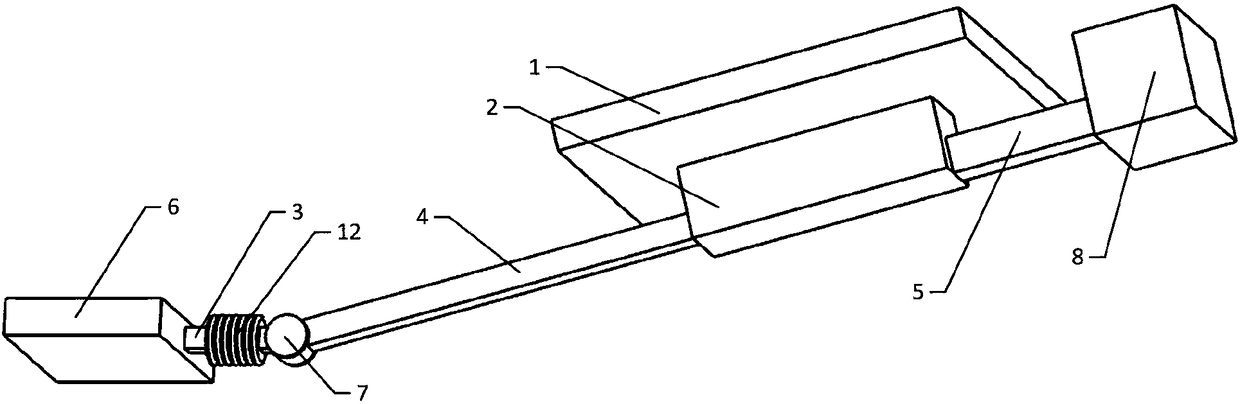

[0033] Embodiment 1: as Figure 1-Figure 2 As shown, a tree-block clearing aerial robot with a retractable and longitudinally curved operating arm includes a multi-rotor platform 1 that provides flight power for the aerial robot, a fuselage 2 fixedly connected directly below the multi-rotor platform 1, and located at the left and right sides of the aerial robot. The middle arm 4 and the rear arm 5 in the plane of symmetry and parallel to the longitudinal axis of the fuselage 2, the forearm 3 connected to the front end of the middle arm 4 through the longitudinal bending joint 7 with a built-in drive motor, the cutter assembly 6 fixedly connected to the front end of the forearm 3, The battery pack 8 fixedly connected to the rear end of the rear arm 5, the middle arm 4 and the rear arm 5 are coaxially movable and nested; the longitudinal bending joint 7 is similar to the mechanical arm of an existing robot, and the mechanical arm is driven by a motor and a reducer to bend, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com