Self-service real training platform and teaching method thereof

A practical training platform and platform technology, applied in the field of teaching platform, can solve the problems of poor experimental course effect, weak experimental connection, rigid arrangement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

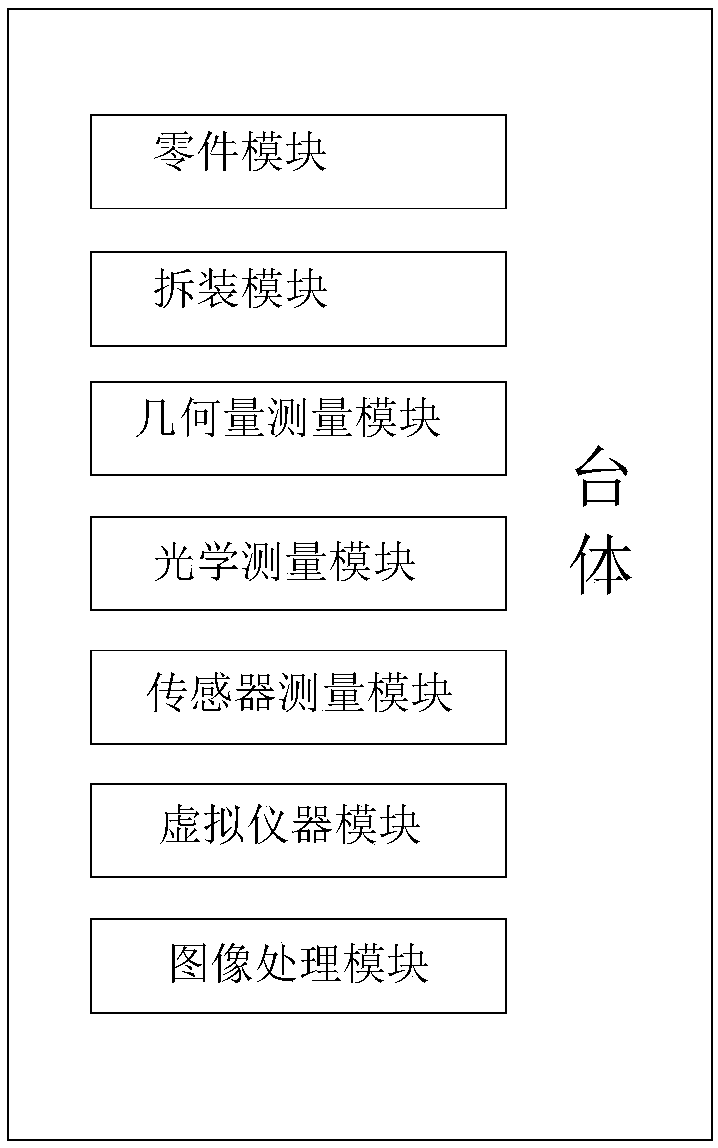

[0025] Such as figure 1 As shown, a self-service training platform includes a platform, the platform is provided with parts modules, the parts modules include a variety of precision machinery, and the platform is provided with disassembly modules for disassembling the precision machinery parts , the platform is also equipped with a geometric quantity measurement module, an optical measurement module, a sensor measurement module, a machine vision measurement module, and a virtual instrument module for processing and analyzing the measured part data.

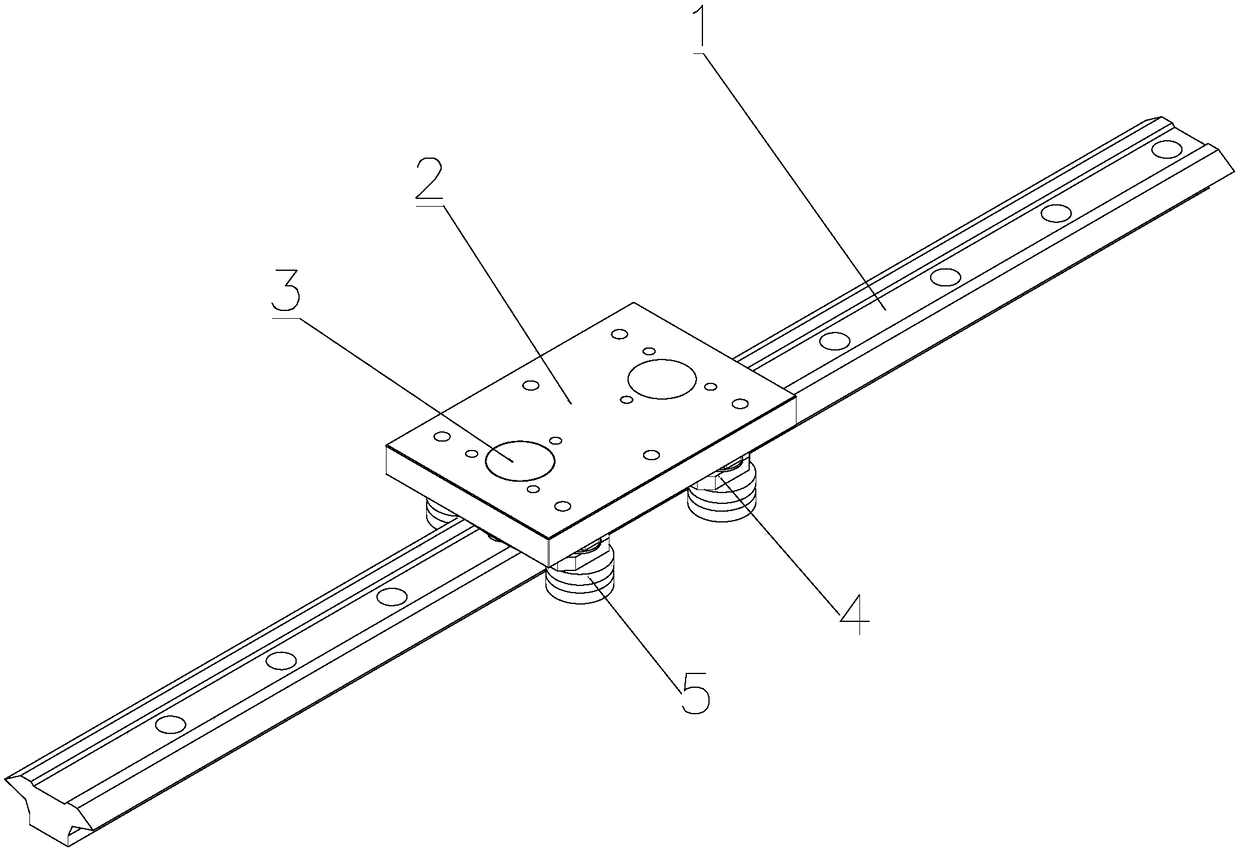

[0026] The parts module includes parts diagrams, parts and assembly diagrams that make up the linear guide rail, the precision turntable, the precision displacement platform, and the joint shaft system of the articulated arm measuring machine. Students can select the assembly drawing in this module to disassemble and assemble, experience the cooperation relationship between the parts that make up the assembly drawing, and compare ...

Embodiment 2

[0034] A teaching method for a self-service training platform, the steps comprising:

[0035] Step 1, select the precision machinery of a kind of self-service training platform as claimed in claim 1;

[0036] Step 2, according to the characteristics and measurement accuracy of the selected precision mechanical feature quantity, the measurement module is required to measure, and the measurement module is a geometric quantity measurement module, an optical measurement module, and a sensor measurement module of a self-service training platform as claimed in claim 1 , Machine vision measurement module;

[0037] Step 3, comparing the measurement results of the same characteristic quantity by different measurement modules, and analyzing the reasons for the differences in measurement results;

[0038] Step 4. Compare the design drawings of the precision machinery with the measurement results of the characteristic quantities, and evaluate the precision machinery;

[0039] Step 5. Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com