System and method with dynamic anti-counterfeiting function

A dynamic and functional technology, applied in the system and system field with dynamic anti-counterfeiting function, can solve different problems and achieve the effect of preventing forgery, protecting product reputation, and improving anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

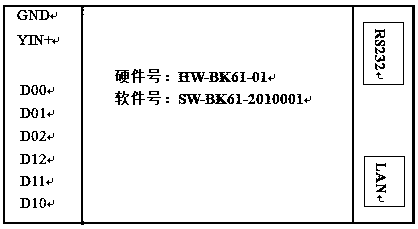

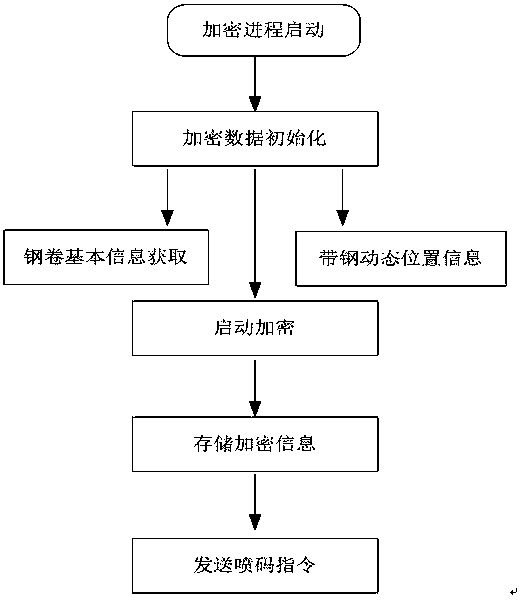

[0024] Embodiment 1: see figure 1 , figure 2 , a system with dynamic anti-counterfeiting function, the system with dynamic anti-counterfeiting function includes L2 seam tracking control module 1, anti-counterfeiting code dynamic generation module 2, inkjet printer communication module 3, inkjet printer printing module 4, dynamic anti-counterfeiting Code and steel coil information storage and query module 5 and inkjet printer remote control module 6, among which the L2 weld seam tracking control module 1 mainly uses the on-site weld seam tracking equipment to track the position of the strip weld seam, and sends it from the PLC to the L2 system Send the welding seam position information, and the anti-counterfeiting system of spraying code receives the welding seam signal from this module; the dynamic anti-counterfeiting code generation module, 2 dynamically generates the anti-counterfeiting code according to the rules; the inkjet printer communication module 3, connects the cod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com