Method for measuring component proportion of ammonium nitrate fuel oil mixture by virtue of saturation oil absorption rate of raw material

A technology of ammonium oil explosives and oil absorption rate, which is applied in the field of explosive technology and equipment, can solve the problems of failure to perform explosion work, inability to guide production in time, and blind blast disposal hazards, etc., to improve the working ability, the method is simple and easy to operate, Significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

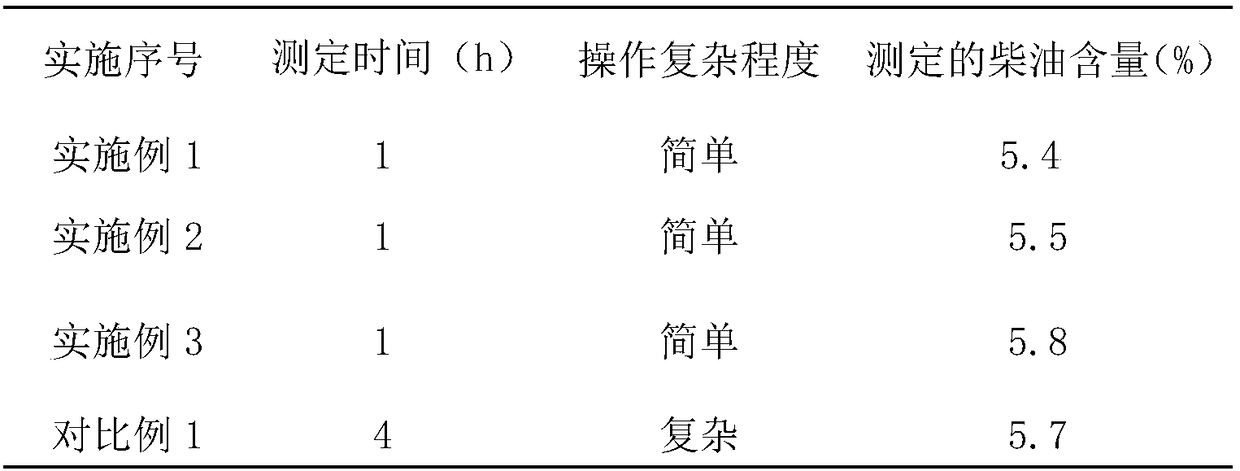

Embodiment 1

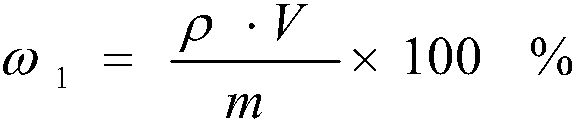

[0033] 1) Determination of saturated oil absorption of porous ammonium nitrate particles:

[0034] Take porous ammonium nitrate particles and weigh 20.0g, place them in a clean and dry 150ml beaker, add enough diesel oil to soak for 15min, transfer the sample to a glass crucible filter, and place the sample in a vacuum greater than 2.7×10 4 Under the condition of Pa, perform suction filtration for 10 minutes until no oil drips down. The sample after the suction filtration is transferred to a clean and dry beaker of known quality and weighed (accurate to 0.1g), to obtain 21.8g of porous ammonium nitrate particles after fully absorbing oil;

[0035] Saturated oil absorption (%) φ=(21.8-20) / 20*100%=9% (Ⅰ)

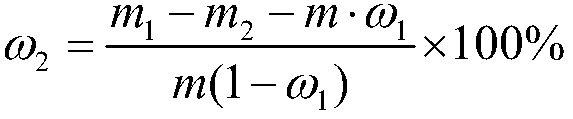

[0036] 2) Re-absorption treatment of ammonium oil explosive sample:

[0037] Get 20.0g of ammonium oil explosive samples prepared by the same batch of porous ammonium nitrate particles as in step 1) and soak them in diesel oil to reach saturation. Weigh in the beaker, obtai...

Embodiment 2

[0049] 1) Determination of saturated oil absorption of porous ammonium nitrate particles:

[0050] Take porous ammonium nitrate particles and weigh 20.0g, place them in a clean and dry 150ml beaker, add enough diesel oil to soak for 15min, transfer the sample to a glass crucible filter, and place the sample in a vacuum greater than 2.7×10 4 Under the condition of Pa, perform suction filtration for 10 minutes until no oil drips down. The sample after the suction filtration is transferred to a clean and dry beaker of known quality and weighed (accurate to 0.1g), to obtain 21.9g of porous ammonium nitrate particles after fully absorbing oil;

[0051] Saturated oil absorption (%) φ=(21.9-20.0) / 20.0×100%=9.5% (I)

[0052] 2) Re-absorption treatment of ammonium oil explosive sample:

[0053] Get and step 1) adopt the ammonium oil explosive sample 20.0g prepared by the same batch of porous ammonium nitrate particles to be soaked in diesel oil to reach saturated state, according to ...

Embodiment 3

[0065] 1) Determination of saturated oil absorption of porous ammonium nitrate particles:

[0066] Take porous ammonium nitrate particles and weigh 20.0g, place them in a clean and dry 150ml beaker, add enough diesel oil to soak for 15min, transfer the sample to a glass crucible filter, and place the sample in a vacuum greater than 2.7×10 4 Under the condition of Pa, perform suction filtration for 10 minutes until no oil drips down. The sample after the suction filtration is transferred to a clean and dry beaker of known quality and weighed (accurate to 0.1g), to obtain 22.0g of porous ammonium nitrate particles after fully absorbing oil;

[0067] Saturated oil absorption (%) φ=(22.0-20.0) / 20.0×100%=10.0% (Ⅰ)

[0068] 2) Re-absorption treatment of ammonium oil explosive sample:

[0069] Get and step 1) adopt the same batch of porous ammonium nitrate particles to prepare, the known diesel oil content is 5.5% ammonium oil explosive sample 20.0g soaks in diesel oil and reaches ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com