A circuit board production device

A technology for production equipment and circuit boards, which is applied to printed circuits, printed circuit manufacturing, and electrical components. It can solve the problems that irritating gases cannot be dispersed quickly and etching liquid is easy to fly out of the etching box, so as to increase the speed. , the effect of ensuring work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below by means of specific embodiments:

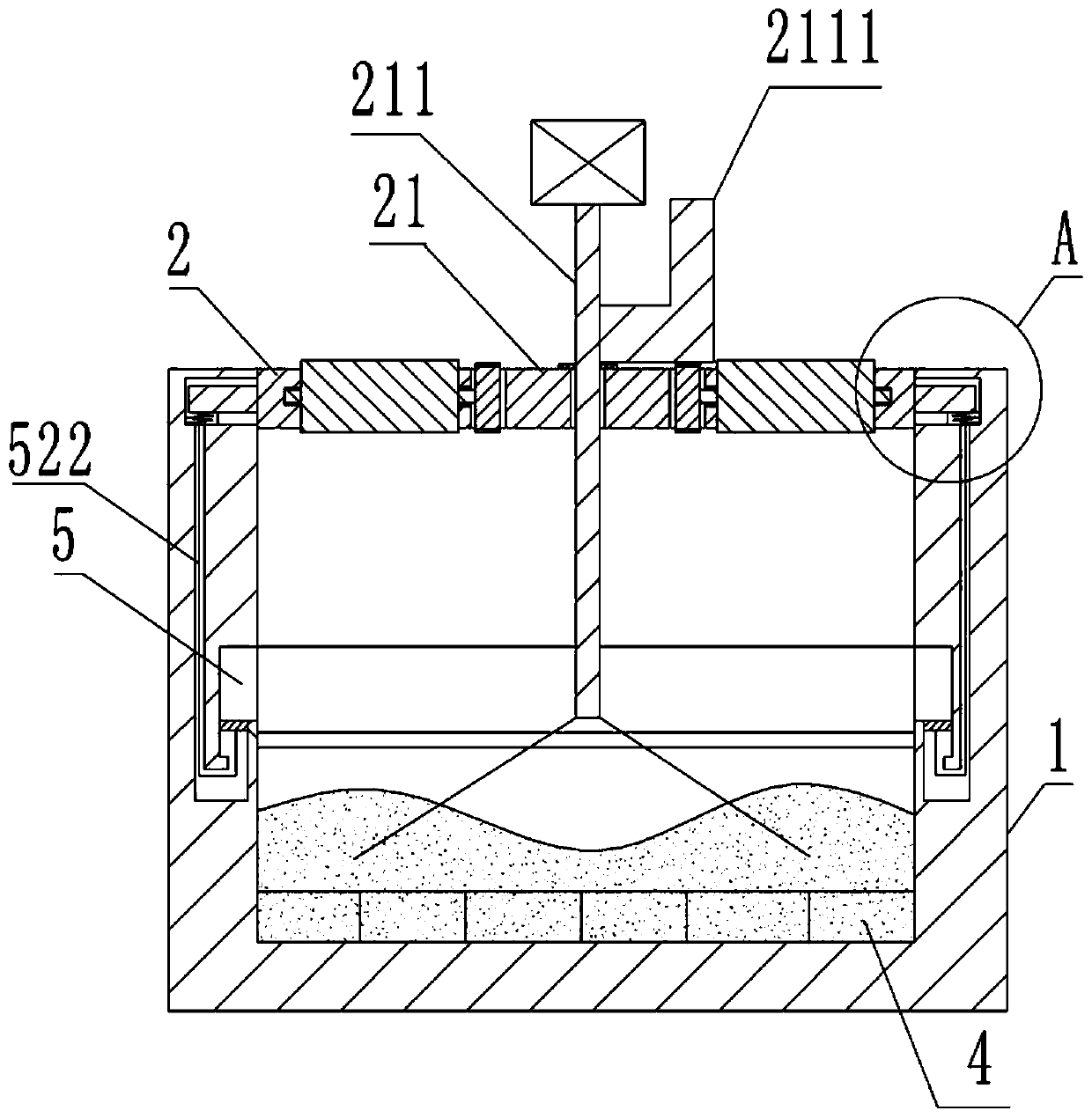

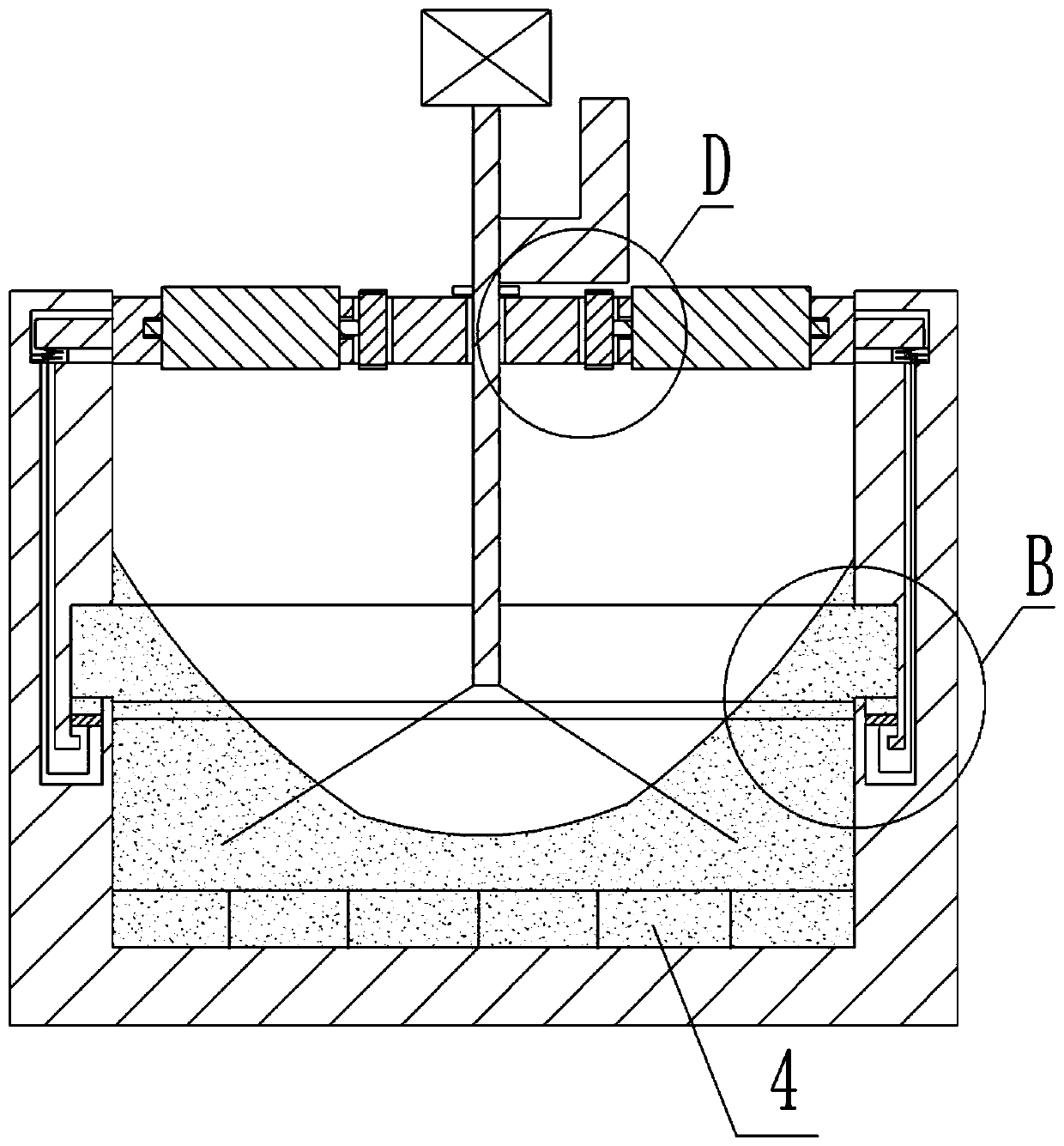

[0036] The reference signs in the drawings of the description include: etching box 1, L-shaped groove 11, annular ring 2, cover plate 21, stirring rod 211, manual rod 2111, connecting rod 22, protrusion 24, rotating plate 3, rotating plate Body 31, rotating shaft 32, torsion spring 321, placement cavity 4, annular groove 5, cavity 51, communication cavity 52, slide plate 521, pull rod 522, elastic layer 6, support plate 61, spring 62, drum 7, rubber layer 71.

[0037] The embodiment is basically as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 Shown:

[0038] The specific implementation process is as follows:

[0039] A circuit board production device, including an etching box 1, and also includes a cover portion for covering the etching box 1, the cover portion includes an annular ring 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com