Polarization beam splitting element and device

A technology of polarization beam splitting and components, applied in polarizing components, optical components, optics, etc., can solve the problems of complex structure, difficult manufacturing process, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

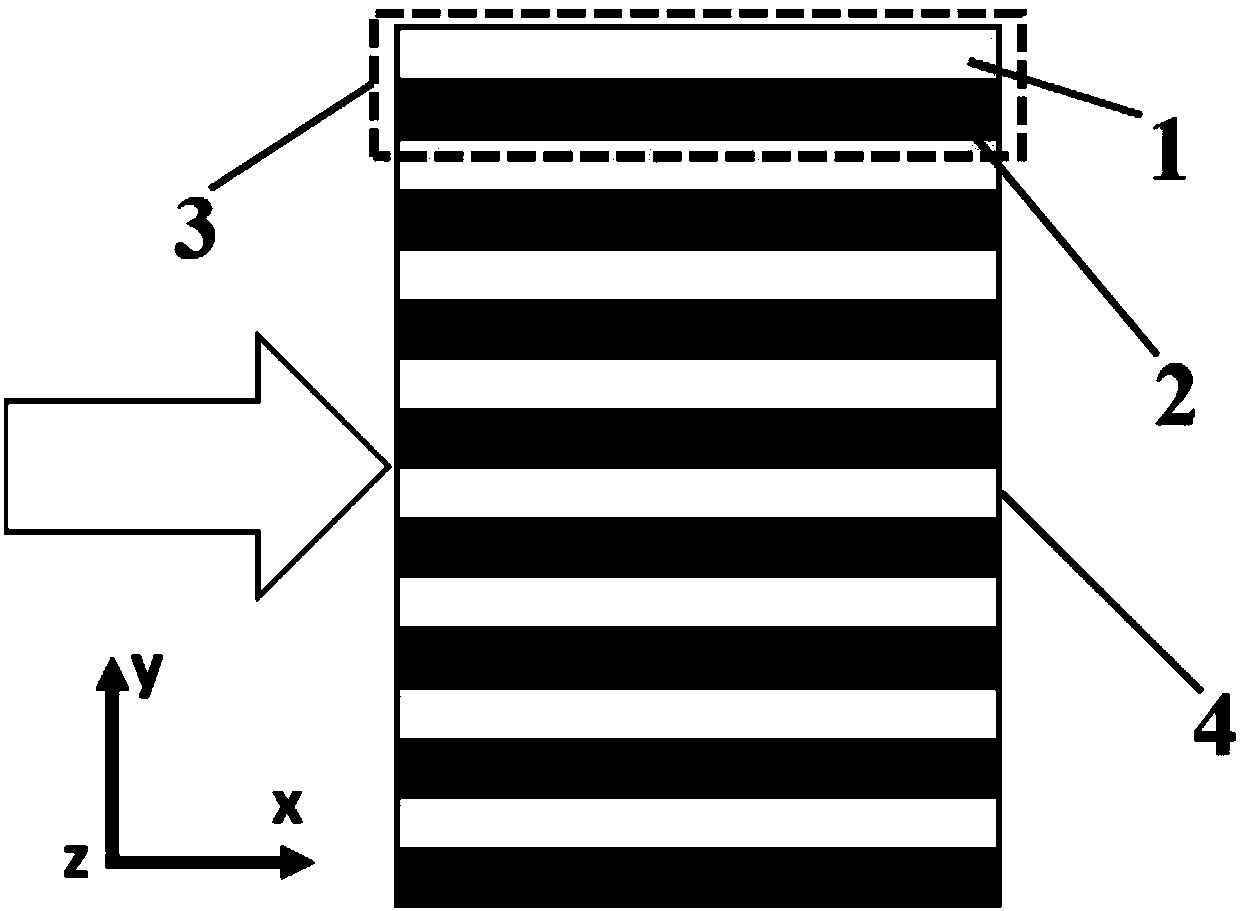

Embodiment 1

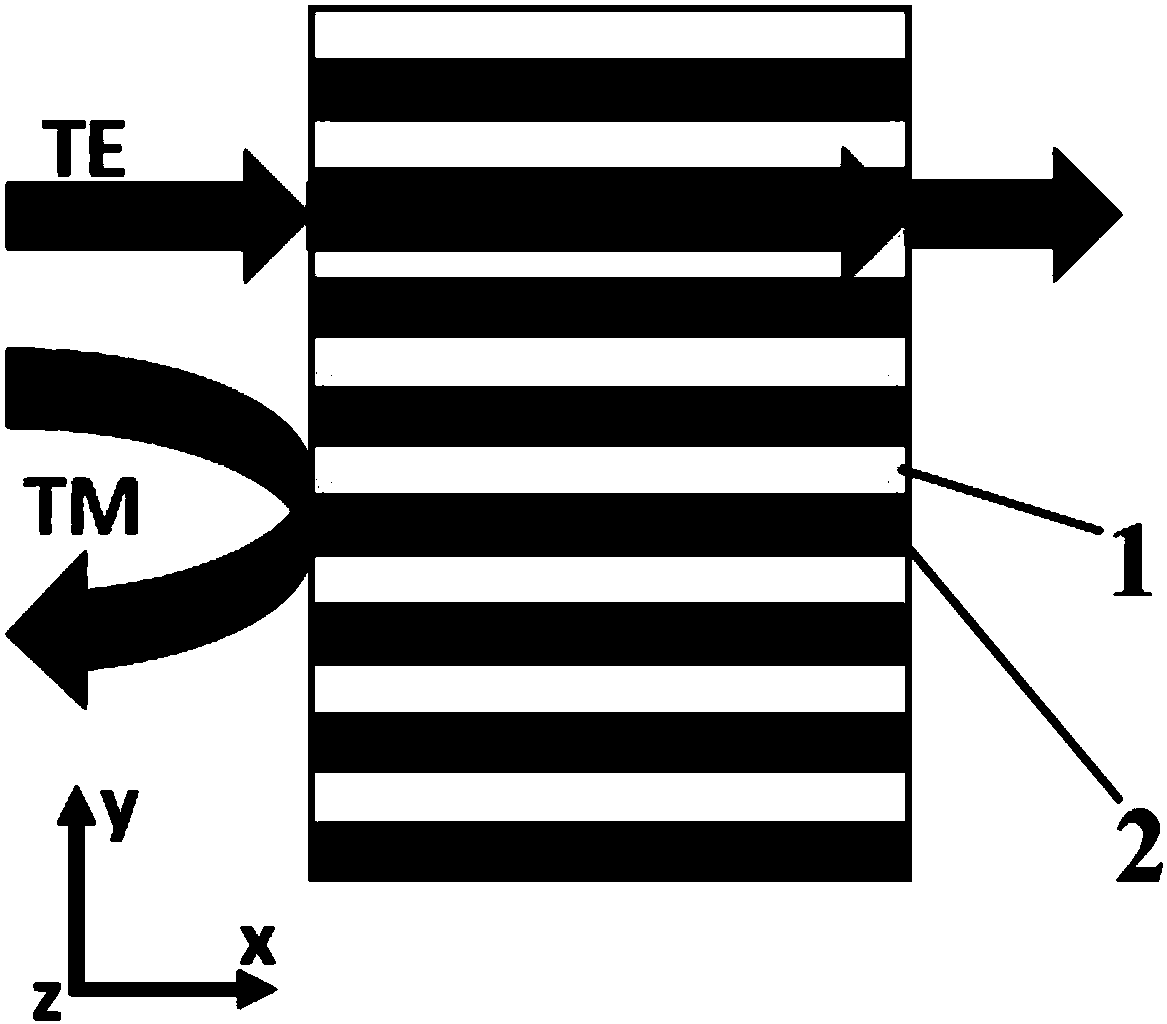

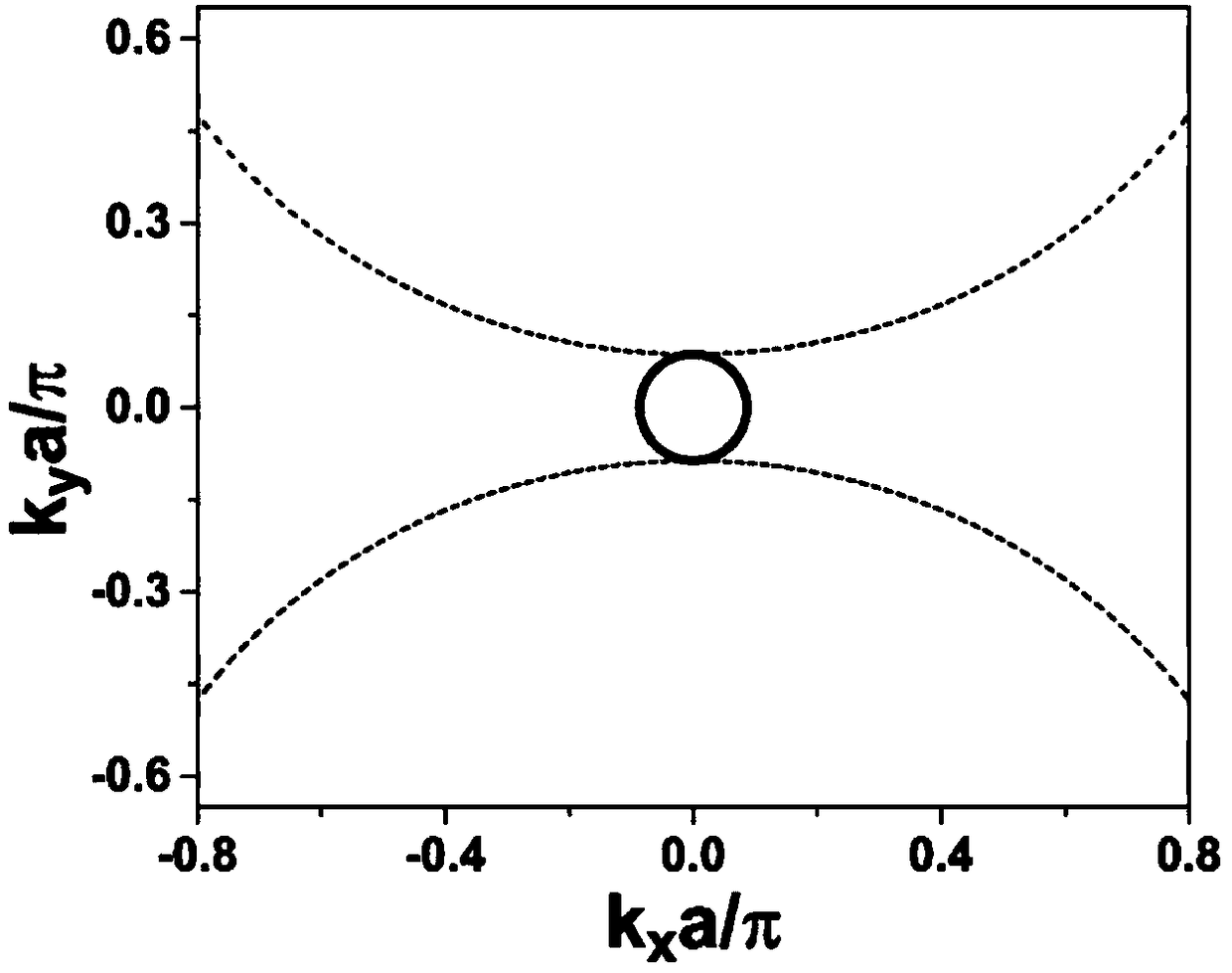

[0057] The parameters of the dielectric film and the metal film are respectively ε d =6,ε m =-2, f d = 0.25 and f m =0.75, the thickness of the periodic repeating unit is a=λ6. At this time, the equal-frequency curves of the polarization beam splitting element 4 are respectively as follows in the TE and TM modes image 3 As shown by the thick solid line and thin dashed line in (normalized frequency fa / c=0.167), it is a very small circle in TE mode, and two disjoint parabolas in TM mode. In this case, when the mixed light of TE mode and TM mode is incident on the side of the multilayer film structure along the direction parallel to the interface of the multilayer film structure (ie, the x direction), due to k y = 0, according to image 3 It can be seen from the equal frequency curve in , that there is a k greater than zero in the TE mode at this time x The solution of , means that the TE wave can propagate in the polarization beam splitting element 4; and for the TM mode,...

Embodiment 2

[0060] The parameters of the dielectric film and the metal film are respectively ε d = 1, ε m =-4, f d = 0.8 and f m =0.2, the thickness of the periodic repeating unit is a=λ / 8. At this time, the equal-frequency curves of the polarization beam splitting element 4 are respectively as follows in the TE and TM modes Figure 7 As shown by the thick solid line and the thin dashed line in (normalized frequency fa / c=0.125), the TE mode is a very small circle, and the TM mode is two intersecting parabolas. In this case, when the mixed light of TE mode and TM mode is incident on the side of the multilayer film structure along the direction parallel to the interface of the multilayer film structure (ie, the x direction), there is k y = 0, according to Figure 7 It can be seen from the equal frequency curve in , that there is a k greater than zero in the TE mode at this time x The solution of , means that the TE wave can propagate in the polarization beam splitting element 4; for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com