Micro mass sensor

A sensor and micro-mass technology, applied in the field of sensors, can solve the problems of small electrostatic driving force, weak amplitude, affecting the accuracy of micro-mass measurement, etc., and achieve the effect of high sensitivity and suppression of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

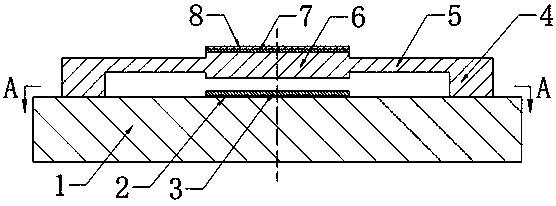

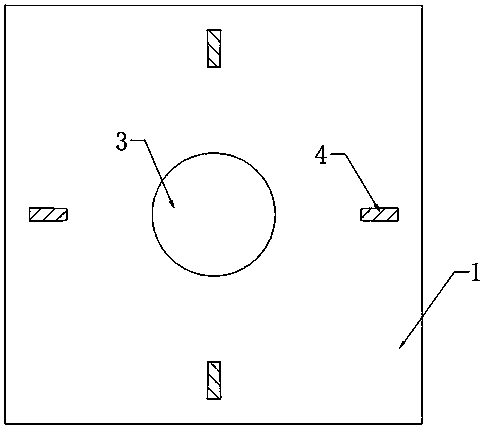

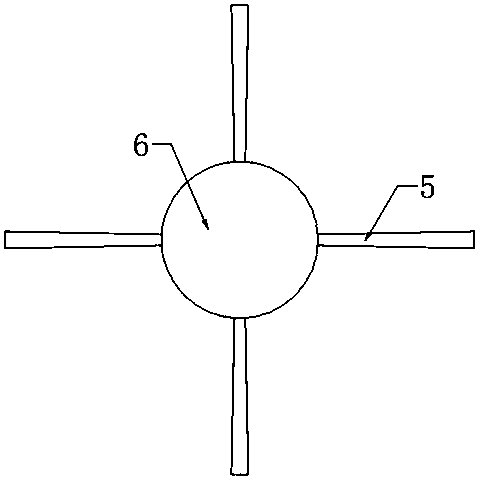

[0019] In an embodiment of the present invention, a micromass sensor includes: a substrate 1, a fixed electrode 2 disposed on the substrate 1, an adsorption layer 8, the fixed electrode is covered with a first insulating layer 3, and the substrate 1 is also provided with A vibration structure, the vibration structure includes a metal movable plate 6, a support beam 5 and an anchor point 4 of the beam, the metal movable plate 6 is connected to the support beam 5, and is fixed on the base 1 through the anchor point 4.

[0020] The movable plate 6 is a rigid circular plate, and each support beam is evenly distributed on the edge of the movable plate 6 . Since the maximum bending stress of the plate-beam structure occurs at the fixed end of the beam, the beam adopts a variable cross-section beam with a large cross-sectional area at the fixed end. The adsorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com