Anode material for electroplating and its preparation method and application

A technology of anode material and copper plating, applied in the direction of electrode, printed circuit manufacturing, printed circuit, etc., can solve the problems of decreased utilization rate of anode materials, neglect of disadvantages, increase of anode slime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

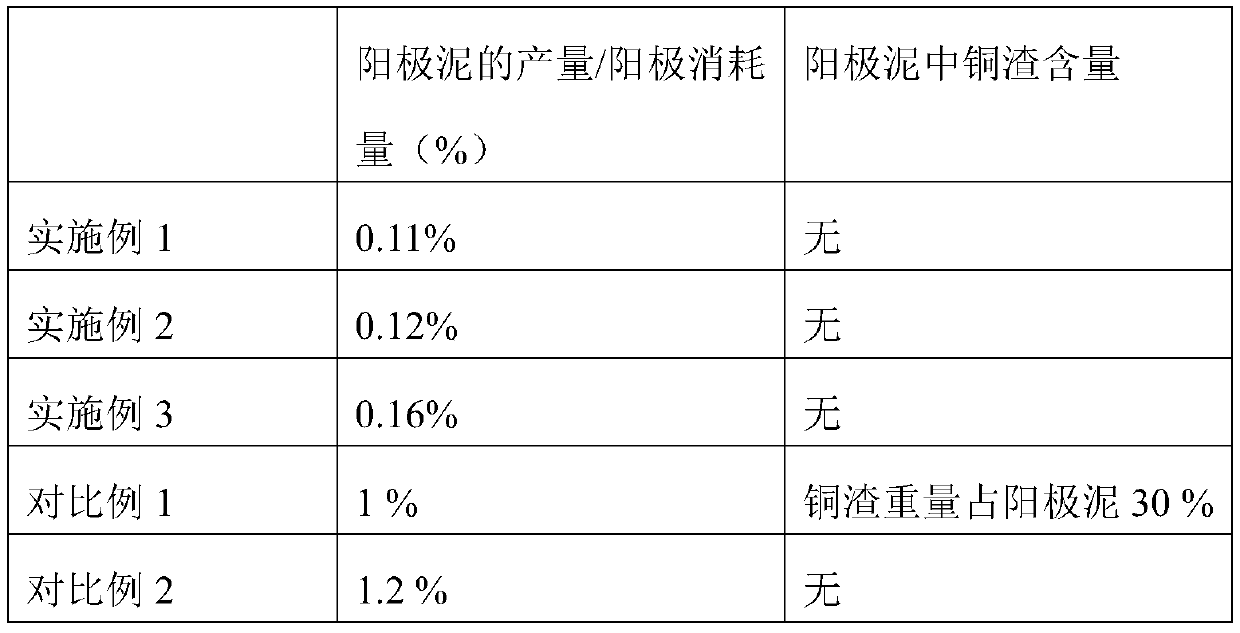

Examples

Embodiment 1

[0028] This embodiment provides an anode material for electroplating and a preparation method thereof, comprising the following steps:

[0029] Step 1: Melting copper and phosphorus by smelting method to obtain phosphor copper melt. Among them, the content of copper is 99.97%, and the content of phosphorus is 0.03%;

[0030] Graphene is added to the phosphorus copper melt at a mass ratio of 1:200000, and dispersed uniformly to obtain a mixed melt; wherein, the particle size of graphene is 50 μm;

[0031] The mixed melt was kept at 1200°C for 30 minutes, and then poured into a mold to obtain an ingot. The ingot was forged and rolled several times at room temperature to obtain an anode material.

[0032] Step 2: Place the above-mentioned anode material in a titanium basket as the anode, and use the PCB board as the cathode, and place it in the copper plating solution. The copper plating solution consists of 240g / L copper sulfate, 50g / L sulfuric acid, 5g / L Guangdong Dongshuo Te...

Embodiment 2

[0035] This embodiment provides an anode material for electroplating and a preparation method thereof, comprising the following steps:

[0036] Step 1: Melting copper and phosphorus by smelting method to obtain phosphor copper melt. Among them, the content of copper is 99.95%, and the content of phosphorus is 0.05%.

[0037] Add activated carbon to the phosphor copper melt at a mass ratio of 1:100000, and disperse evenly to obtain a mixed melt; wherein, the particle size of the activated carbon is 20 μm;

[0038] The mixed melt was kept at 1200°C for 30 minutes, and then poured into a mold to obtain an ingot. The ingot was forged and rolled several times at room temperature to obtain an anode material.

[0039] Step 2: Place the above-mentioned anode material in a titanium basket as the anode, and use the PCB board as the cathode, and place it in the copper plating solution. The copper plating solution consists of 240g / L copper sulfate, 50g / L sulfuric acid, 5g / L Guangdong Do...

Embodiment 3

[0042] This embodiment provides an anode material for electroplating and a preparation method thereof, comprising the following steps:

[0043] Step 1: Melting copper and phosphorus by smelting method to obtain phosphor copper melt. Among them, the content of copper is 99.96%, and the content of phosphorus is 0.04%;

[0044] Add carbon nanotubes to the phosphorus copper melt at a mass ratio of 1:300000, and disperse evenly to obtain a mixed melt; wherein, the average diameter of the carbon nanotubes is about 100 nm, and the average length of the tubes is about 80 μm;

[0045] The mixed melt was kept at 1200°C for 30 minutes, and then poured into a mold to obtain an ingot. The ingot was forged and rolled several times at room temperature to obtain an anode material.

[0046]Step 2: Place the above-mentioned anode material in a titanium basket as the anode, and use the PCB board as the cathode, and place it in the copper plating solution. The copper plating solution consists of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com