Graphene water-borne epoxy wear-resistant self-leveling paint and preparation method thereof

An alkene water-based, self-leveling technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of inconvenient use, high preparation cost, short storage time, etc., and achieve convenient use, good stability, high wear resistance and durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

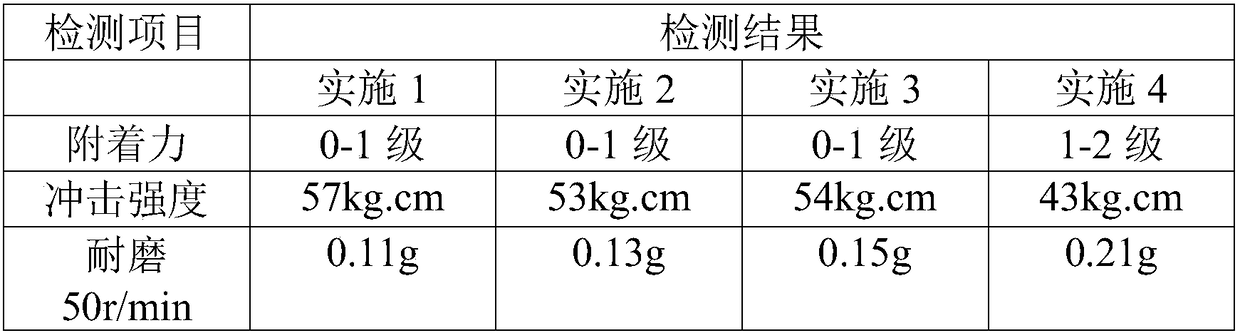

Examples

Embodiment 1

[0028] A kind of graphene water-based epoxy wear-resistant self-leveling coating, this coating is made up of AB two components, and the mass ratio of AB component is 1:3, and described A component is epoxy resin, 25 parts; Described B The components are composed of solvent, dispersant, defoamer, wetting agent, filler, graphene, curing agent, defoamer and leveling agent, etc. by mass fraction as follows: 25 parts of solvent deionized water, 0.3 parts of dispersant part, 0.5 part of defoamer, 0.5 part of wetting agent, 8.5 parts of filler, 2 parts of graphene, 37.5 parts of curing agent, 0.5 part of defoamer, and 0.2 part of leveling agent.

[0029] Its preparation process is as follows:

[0030] S1. Epoxy resin, deionized water, dispersant, defoamer, wetting agent and filler are added to the reactor and mixed in turn, and the graphene material is added under the stirring condition of 3000rpm. The adding time of the graphene material is 30min, stir until evenly dispersed and th...

Embodiment 2

[0033] A kind of graphene water-based epoxy wear-resistant self-leveling coating, this coating is made up of AB two components, and the mass ratio of AB component is 1:5, and described A component is epoxy resin, 17 parts; Described B The components consist of solvent, dispersant, defoamer, wetting agent, filler, graphene, curing agent, defoamer and leveling agent, etc., by mass fraction: 20 parts of deionized water, 1 part of dispersant, 1 part of foaming agent, 1 part of wetting agent, 15 parts of filler, 5 parts of graphene, 40 parts of curing agent, 1 part of defoamer, and 1 part of leveling agent.

[0034] Its preparation process is as follows:

[0035] S1. Epoxy resin, deionized water, dispersant, defoamer, wetting agent and filler are added to the reactor and mixed in sequence, and the graphene material is added under the stirring condition of 4000rpm. The adding time of the graphene material is 50min, stir until evenly dispersed and then filter; after filtering, take ...

Embodiment 3

[0038] A kind of graphene water-based epoxy wear-resistant self-leveling coating, this coating is made up of AB two components, and the mass ratio of AB component is 1:4, and described A component is epoxy resin, 4.65 parts; Described B The components consist of solvent, dispersant, defoamer, wetting agent, filler, graphene, curing agent, defoaming agent and leveling agent, etc., by mass fraction: 10 parts of deionized water, 0.1 part of dispersant, 0.1 part of foaming agent, 0.2 part of wetting agent, 5 parts of filler, 1 part of graphene, 2 parts of curing agent, 0.1 part of defoamer, and 0.1 part of leveling agent.

[0039] Its preparation process is as follows:

[0040] S1. Epoxy resin, deionized water, dispersant, defoamer, wetting agent and filler are added to the reactor and mixed in turn, and the graphene material is added under the stirring condition of 2000rpm. The adding time of the graphene material is 20min, stir until evenly dispersed and then filter; after filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com