A kind of electrochemical preparation method of fluorinated graphene material

A technology of fluorinated graphene and fluorinated graphite, which is applied in the field of electrochemical preparation of fluorinated graphene materials, can solve the problems of difficult preparation, serious environmental pollution, experimental conditions and high operation requirements, and achieve simple equipment and process, The effect of low preparation cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

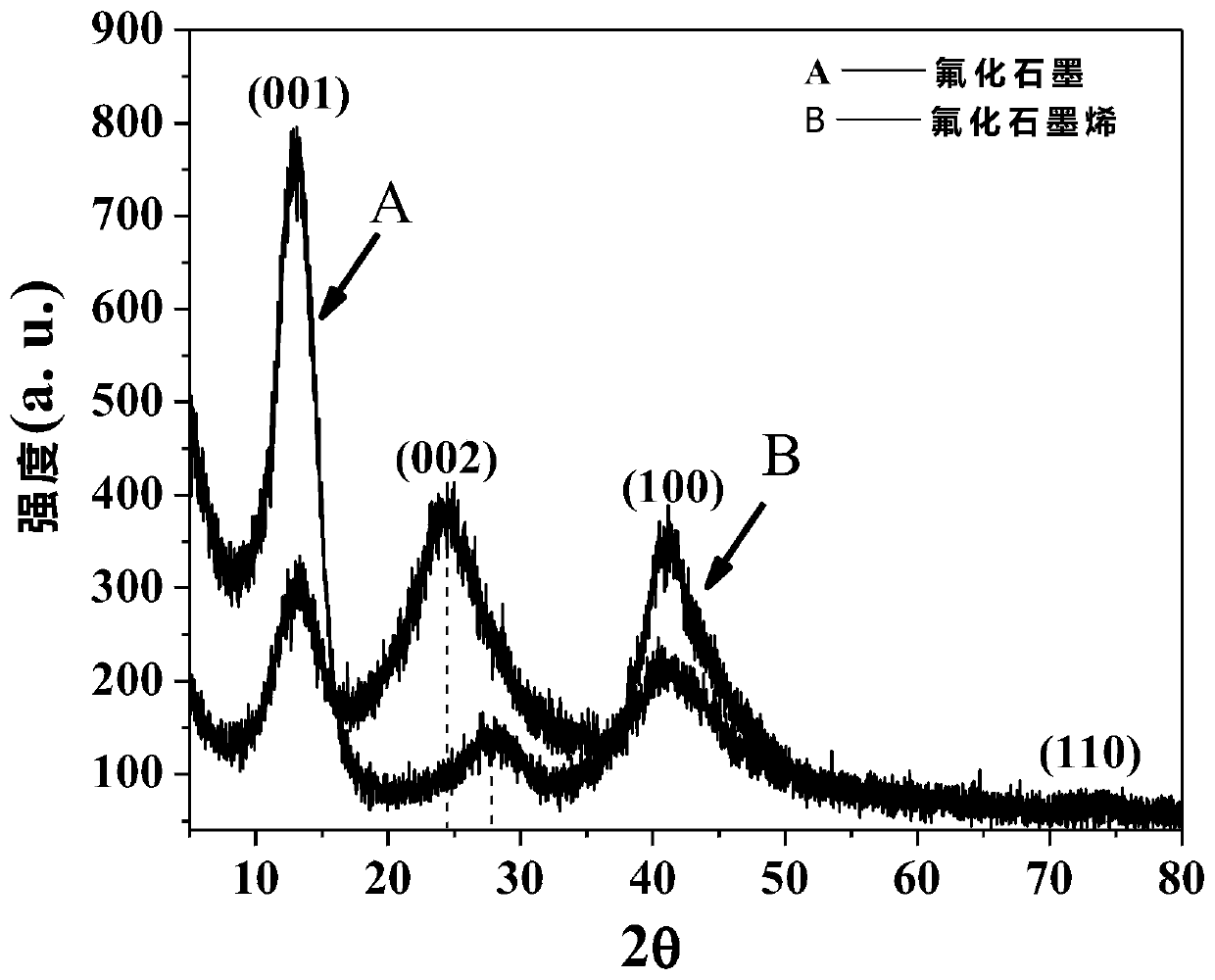

Embodiment 1

[0050] Weigh 40 mg of fluorinated graphite, press it on the aluminum foil with a tablet press, and obtain a fluorinated graphite electrode material, use the prepared electrode material as the positive electrode, and the lithium sheet as the negative electrode; use LiPF 6 It is an electrolyte with a concentration of 1M and EC and DMC with a volume ratio of 1:1 as a solvent; it is assembled into a battery and discharged for 20 hours at a rate of 0.025C.

[0051] After the discharge is over, open the battery, take out the aluminum foil, scrape off the positive electrode material on it, and then disperse it in NMP for ultrasonic peeling. The dispersion was subjected to centrifugation, the lower precipitated part was removed, and the upper part was separated, filtered and freeze-dried. Collect samples.

Embodiment 2

[0053] Weigh 30 mg of graphite fluoride, and press it on an aluminum foil with a tablet press to obtain a graphite fluoride electrode material. The prepared electrode material is used as the positive electrode, and the lithium sheet is used as the negative electrode; the LiPF 6 As the electrolyte, EC and DMC with a concentration of 1M and a volume ratio of 1:1 are used as solvents; assembled into batteries. Discharge for 10 hours at a rate of 0.04C.

[0054]After the discharge is over, open the battery, take out the aluminum foil, scrape off the positive electrode material on it, and then disperse it in NMP for ultrasonic peeling. The dispersion was subjected to centrifugation, the lower precipitated part was removed, and the upper part was separated, filtered and freeze-dried. Collect samples.

Embodiment 3

[0056] Weigh 20 mg of graphite fluoride, and press it on an aluminum foil with a tablet press to obtain a graphite fluoride electrode material. The prepared electrode material is used as the positive electrode, and the lithium sheet is used as the negative electrode; the LiPF 6 It is an electrolyte with a concentration of 1M and EC, DEC, and DMC with a volume ratio of 1:1:1 as a solvent; it is assembled into a battery. Discharge for 30 hours at a rate of 0.01C.

[0057] After the discharge is over, open the battery, take out the aluminum foil, scrape off the positive electrode material on it, and then disperse it in NMP for ultrasonic peeling. The dispersion was subjected to centrifugation, the lower precipitated part was removed, and the upper part was separated, filtered and freeze-dried. Collect samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com