Vacuum cup based on particulate matter moulding

A technology of vacuum suction cups and particulate matter, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems that the conformability of double-sided tape is difficult to ensure air tightness, the surface damage of objects, and the inability to meet multi-variety and small-batch production lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

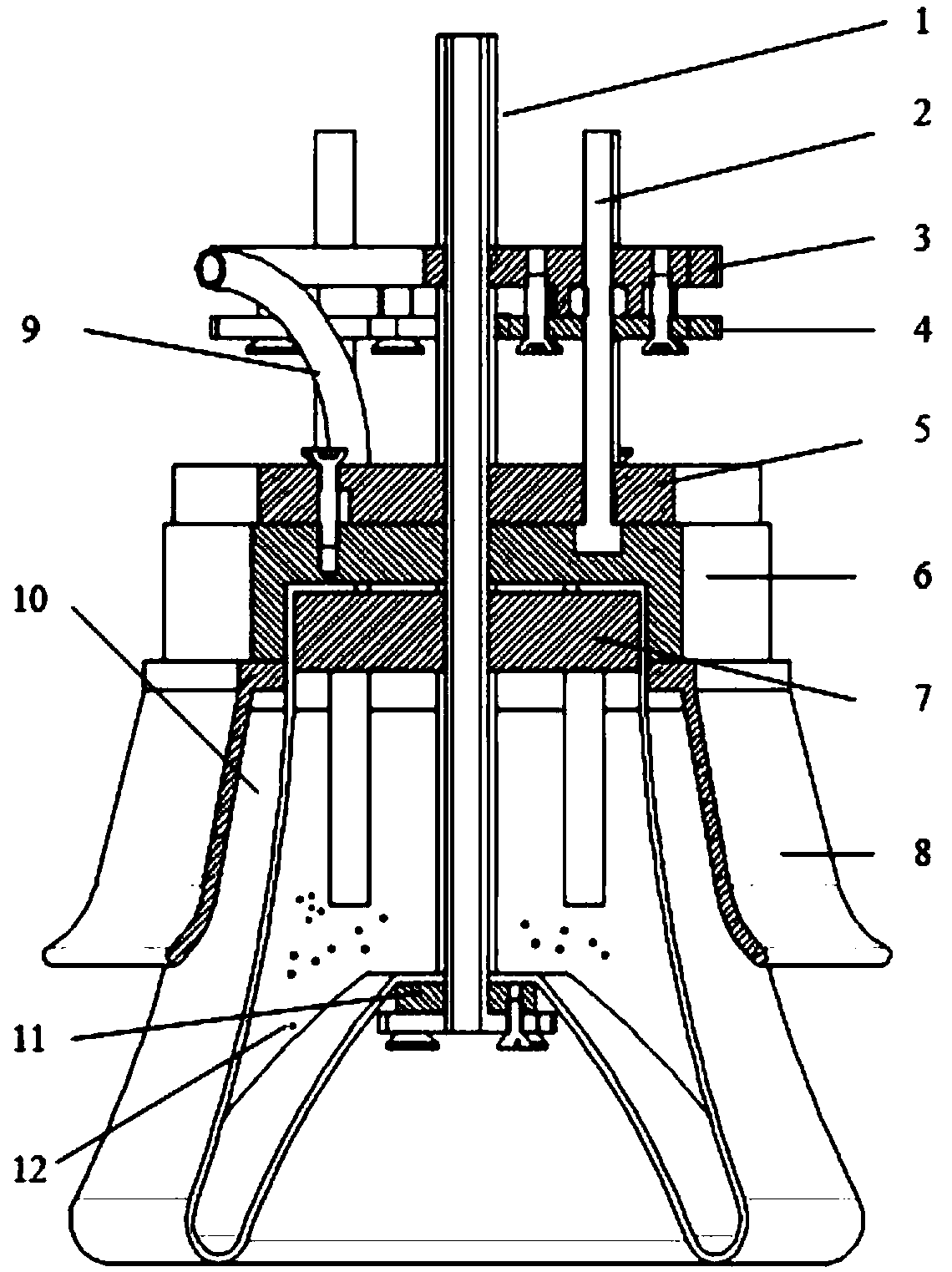

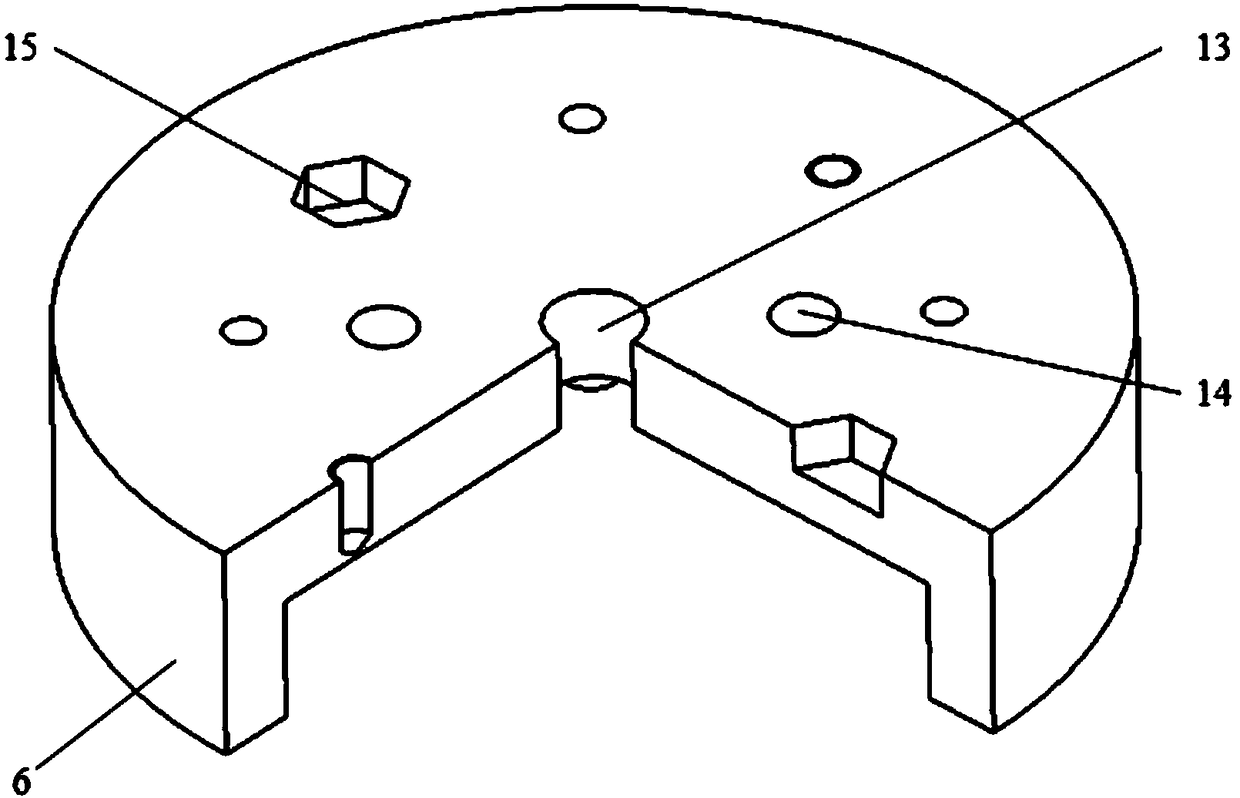

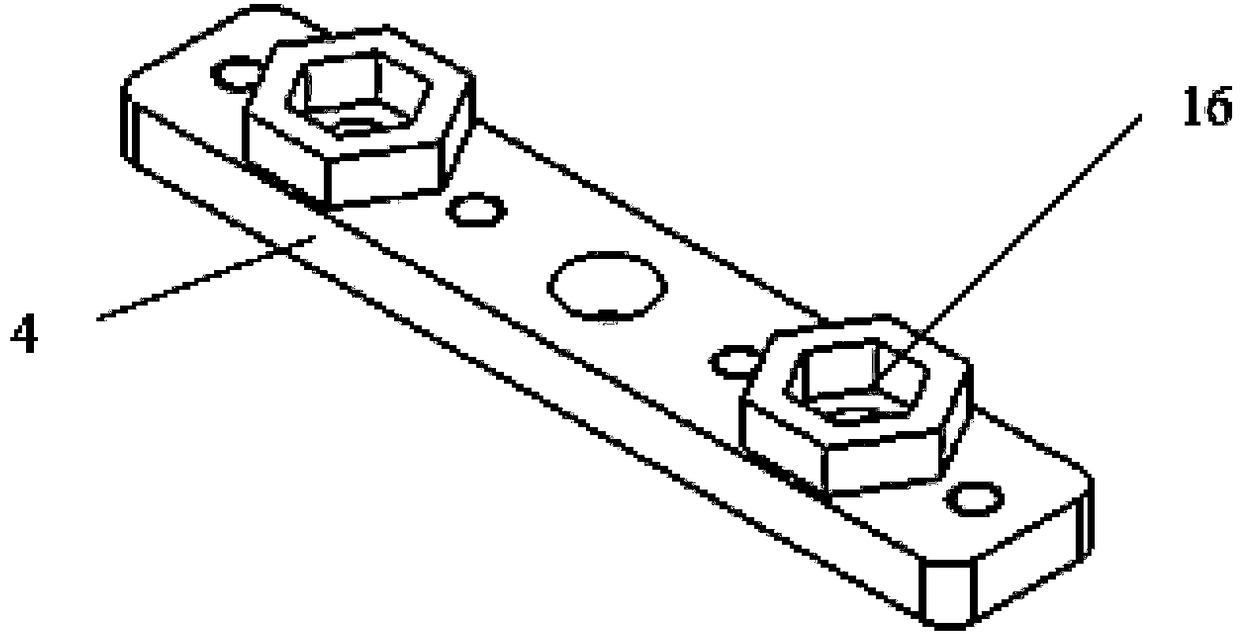

[0039] Below in conjunction with the accompanying drawings, the working process of vacuum suction cup adsorption and clamping of the present invention will be further elaborated:

[0040] The first hose 11 is connected to the first positive pressure source for air supply, and the second hose 9 is connected to the second positive pressure source for air supply. The air pressures of the two positive pressure sources are inconsistent, and at the same time, the air path of the first hose 1 is paralleled for vacuum generation. The air source of the vacuum generator adopts the third positive pressure source to supply air, and the vacuum generator is also connected in parallel in the air circuit of the second hose 9, and the vacuum generator in this air circuit adopts the fourth positive pressure source to supply air.

[0041] First, move the vacuum chuck over the workpiece, and then use a second positive pressure source to supply air to the inside of the film 10 during the descent, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com