Glazing unit for underwater objects

A technology for glass windows and objects, which is applied to underwater operation equipment, glass/slag layered products, ship windows, etc. The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

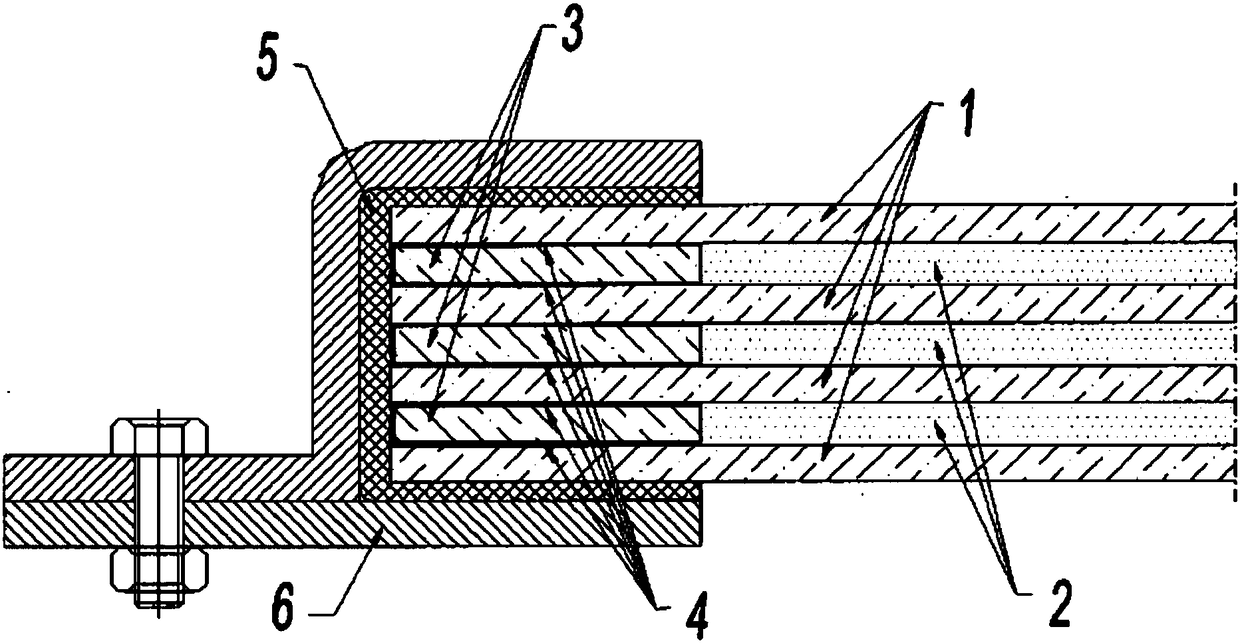

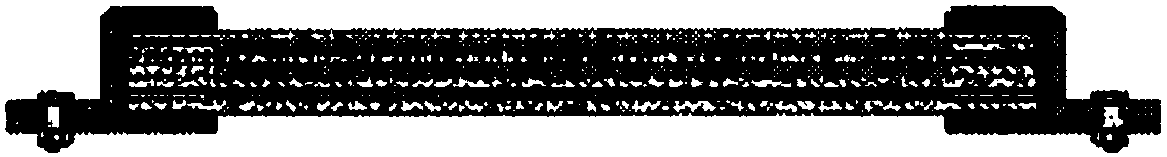

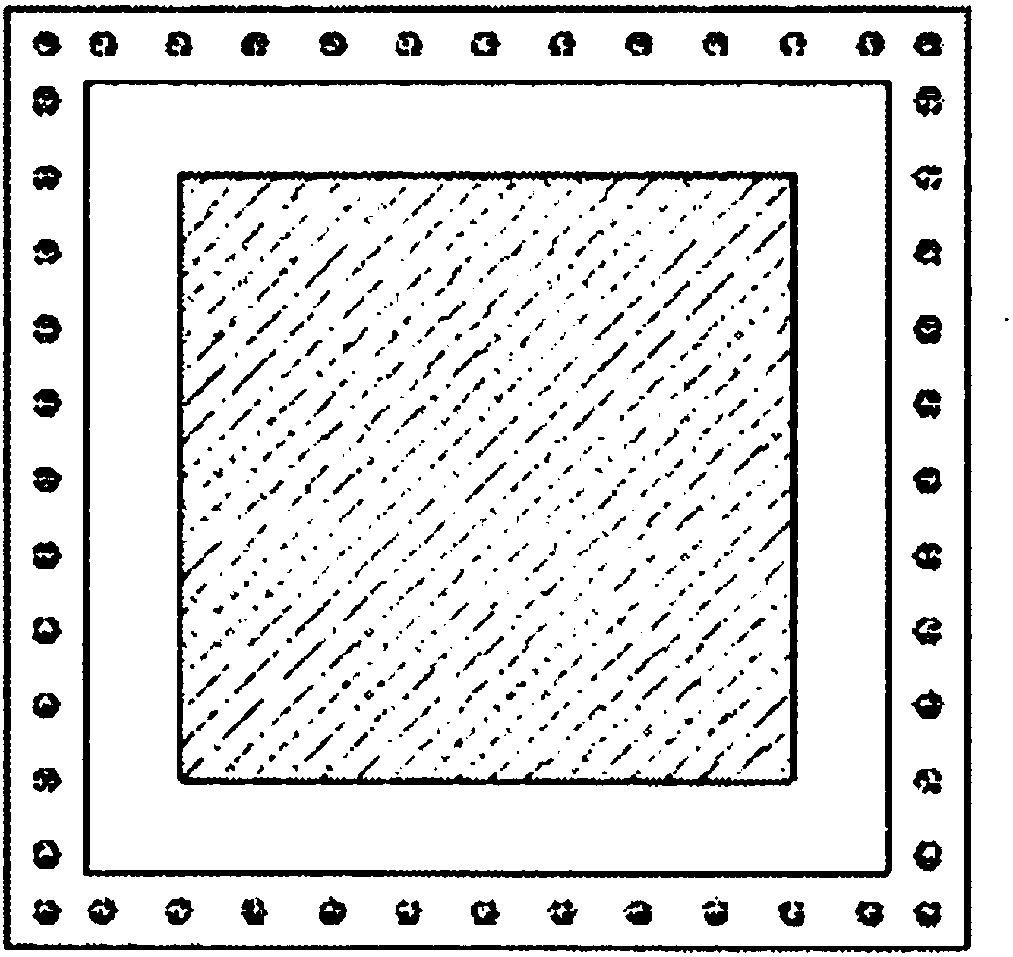

[0023] Glazing units for windows of underwater objects consist of plates of mineral glass placed in circumferential clamping rings. The glazing unit has two sheets 1 of mineral glass separated by a thin layer of compressible liquid 2 . On the boundary between the mineral glass plates 1 there is a circumferential spacer 3 made of mineral glass, which has a seal 4 in the contact area with the mineral glass plates 1 , and a set of strips constructed Mineral glass pane 1 with circumferential spacer 3 and seal 4 adjoins a circumferential seal 5 clamped by a circumferential clamping ring.

example 2

[0025] Glazing units for windows of underwater objects consist of plates of mineral glass placed in circumferential clamping rings. The glazing unit has two sheets 1 of mineral glass separated by a thin layer of compressible liquid 2 . The thickness of the liquid layer 2 located between the mineral glass panes 1 is equal to the layer thickness of the mineral glass panes 1 . On the boundary between the mineral glass plates 1 there is a circumferential spacer 3 made of mineral glass, which has a seal 4 in the contact area with the mineral glass plate 1 , and the seal 4 is closed shape and borders the upper and lower borders of the mineral glass plate 1. A configured set of mineral glass plates 1 with circumferential spacers 3 and seals 4 adjoins a circumferential seal 5 clamped by a circumferential clamping ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com