A control method based on wireless communication for adding and uncapping the lid of molten iron tank

A wireless communication and device control technology, which is applied in the safety/control of capping machines, electrical program control, electric operating devices, etc., can solve the problems of low safety, long scheduling time, large heat loss of empty iron tanks and heavy tanks and other issues, to achieve the effect of ensuring personal safety, reducing operating time, and reducing labor intensity

Active Publication Date: 2019-10-01

WUHAN KEHONG IND FURNACE

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the running time of the molten iron tank car is about 8 hours from the maintenance workshop-taphole-desulphurization workshop-steelmaking workshop-maintenance workshop. Problems such as large heat loss of empty tanks and heavy tanks

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

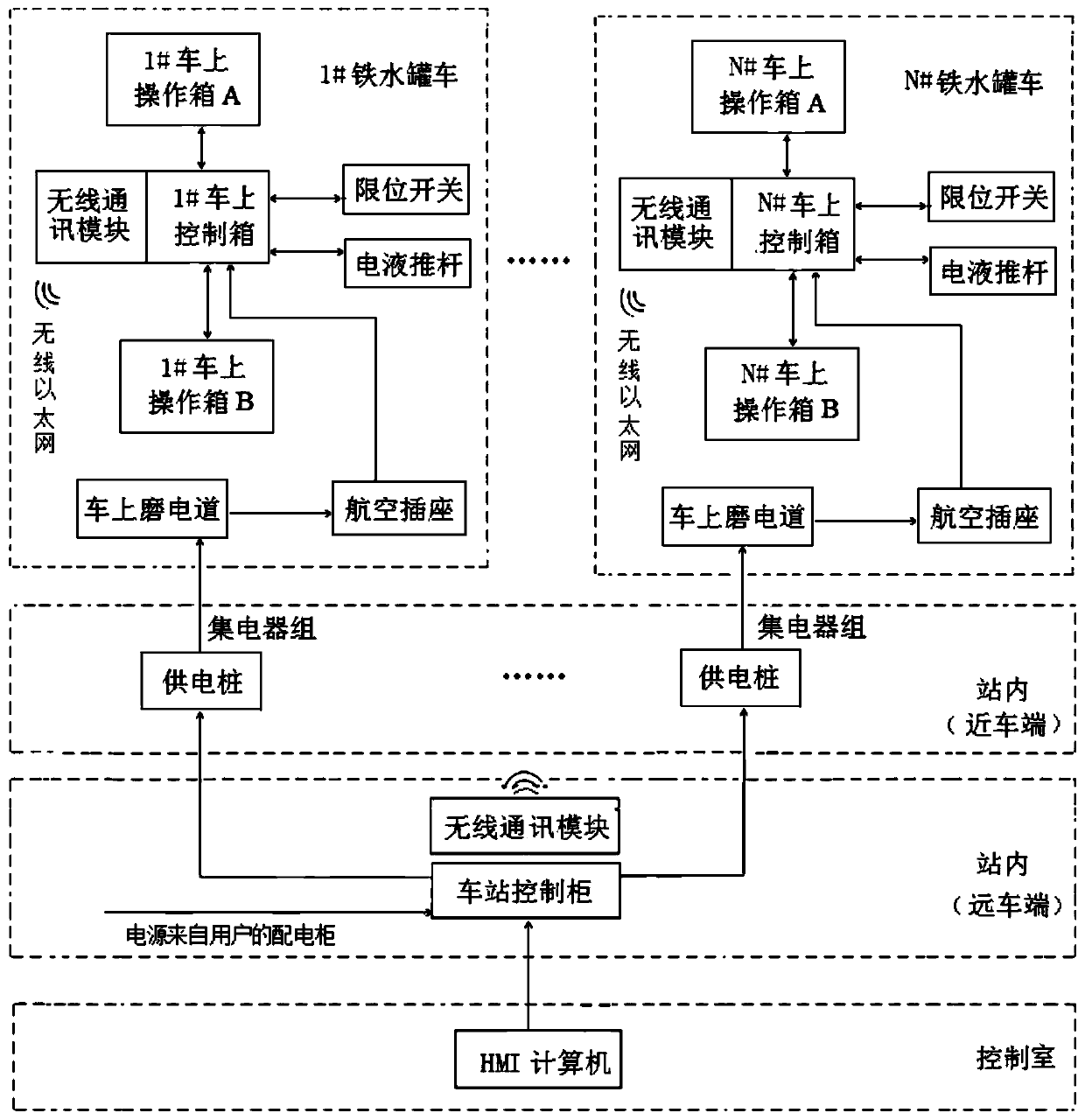

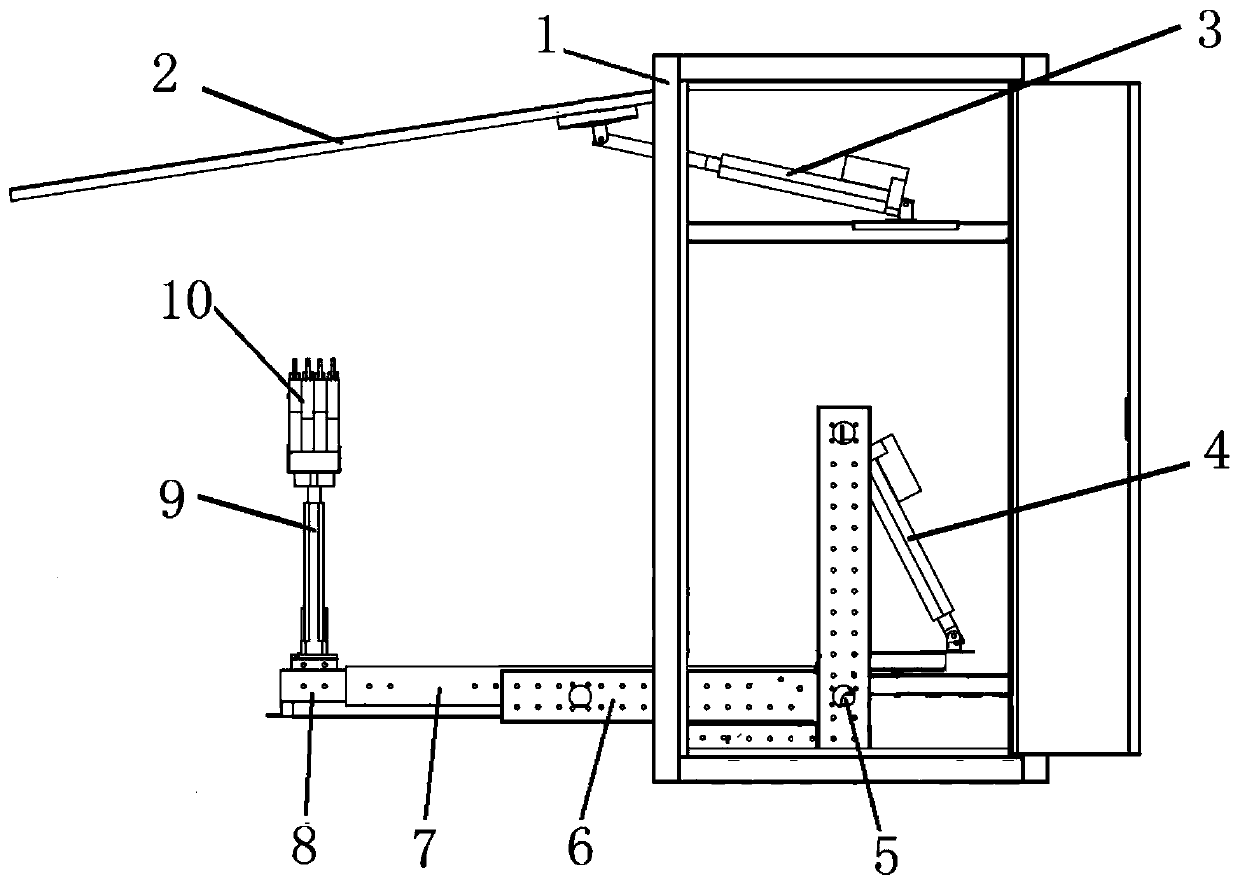

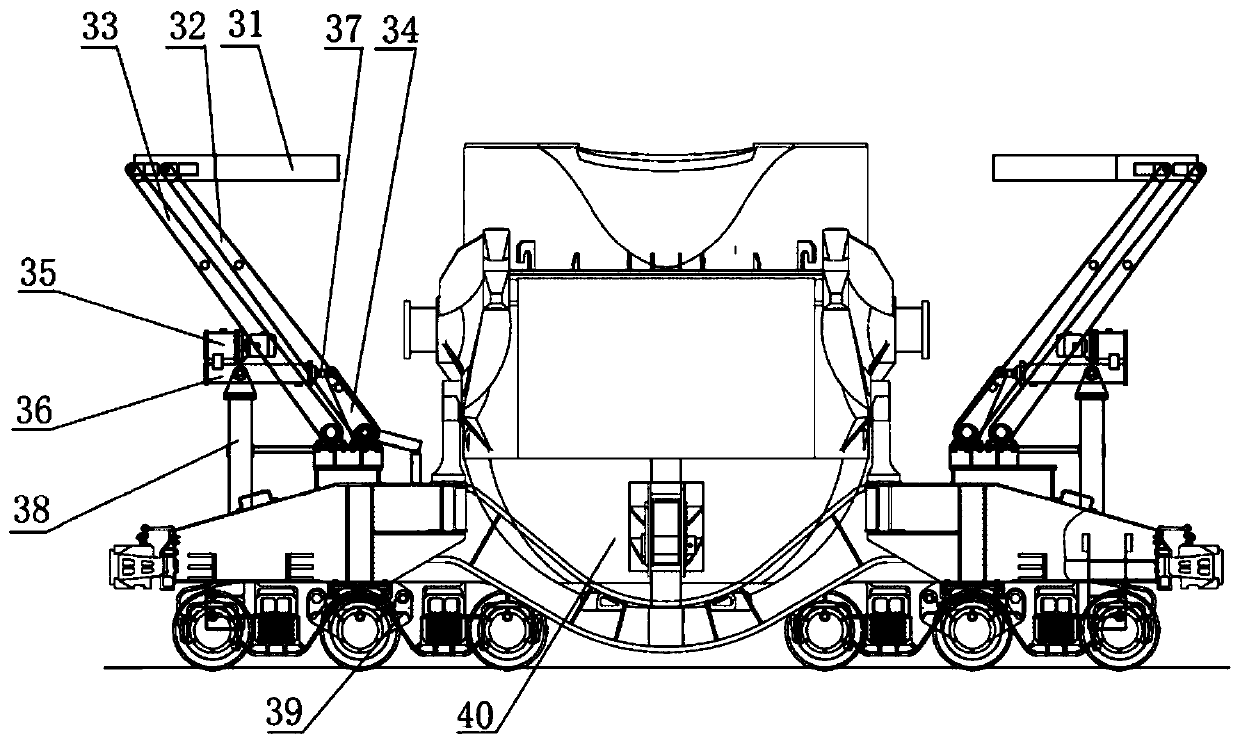

The invention relates to a hot metal bottle lid capping and uncovering device control method based on wireless communication. A hot metal ladle capping and uncovering control system based on wirelessEthernet communication is firstly established. The system comprises an on-vehicle control box installed on a hot metal bottle vehicle, on-vehicle operating boxes A and B, a power supply pile, a station control cabinet, a control room HMI computer and a hot metal ladle capping and uncovering device installed on the hot-metal bottle vehicle. The method comprises the following steps of using the station control cabinet or an HMI operating power supply pile to provide power for equipment on the hot metal bottle vehicle; and on the hot-metal bottle vehicle, through the on-vehicle control box, selecting a remote / on-site switch, wherein if the remote switch is selected, a control room HMI remotely controls the operation of hot metal ladle capping and uncovering, and if the on-site switch is selected, the on-vehicle control box completes the hot metal ladle capping and uncovering. In the invention, Remote operation means at a safety position can be provided for the control of the hot metal ladle capping and uncovering, and when the hot metal bottle vehicle arrives at a station, concentration monitoring can be immediately performed and the operation of rapid capping and uncovering is realized. By using the method, operation is simple and high-efficient, and safety is high.

Description

technical field The present invention relates to a method for controlling a device for adding and removing lids of molten iron tanks based on wireless communication, in particular to a method of using wireless Ethernet to implement equipment installed on molten iron tankers and power supply piles at the station near the vehicle end of the molten iron tanker parking station. The wireless communication between the station control cabinet at the remote train end and the HMI computer in the control room, and the PLC controller installed in the train control box and station control cabinet to realize the remote detection and control of the equipment to complete the ladle on the molten iron tanker A control method for capping and uncapping operations. Background technique The molten iron tanker is a special platform used for metallurgical enterprises to transport molten iron to the cast iron machine for pouring iron blocks or to the steelmaking workshop to inject the molten iron i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05B19/05B67B7/00B67B3/26

Inventor 戴方钦李峰郭悦魏骏游永华吕伟陈兵

Owner WUHAN KEHONG IND FURNACE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com