an automatic transmission

A technology of automatic transmission and linkage components, applied in the direction of magnetic drive clutch, non-mechanical drive clutch, clutch, etc., can solve the problems of inconvenient control, bulky overall structure of the transmission, etc., and achieve easy control, simple and reliable structure, and improved applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

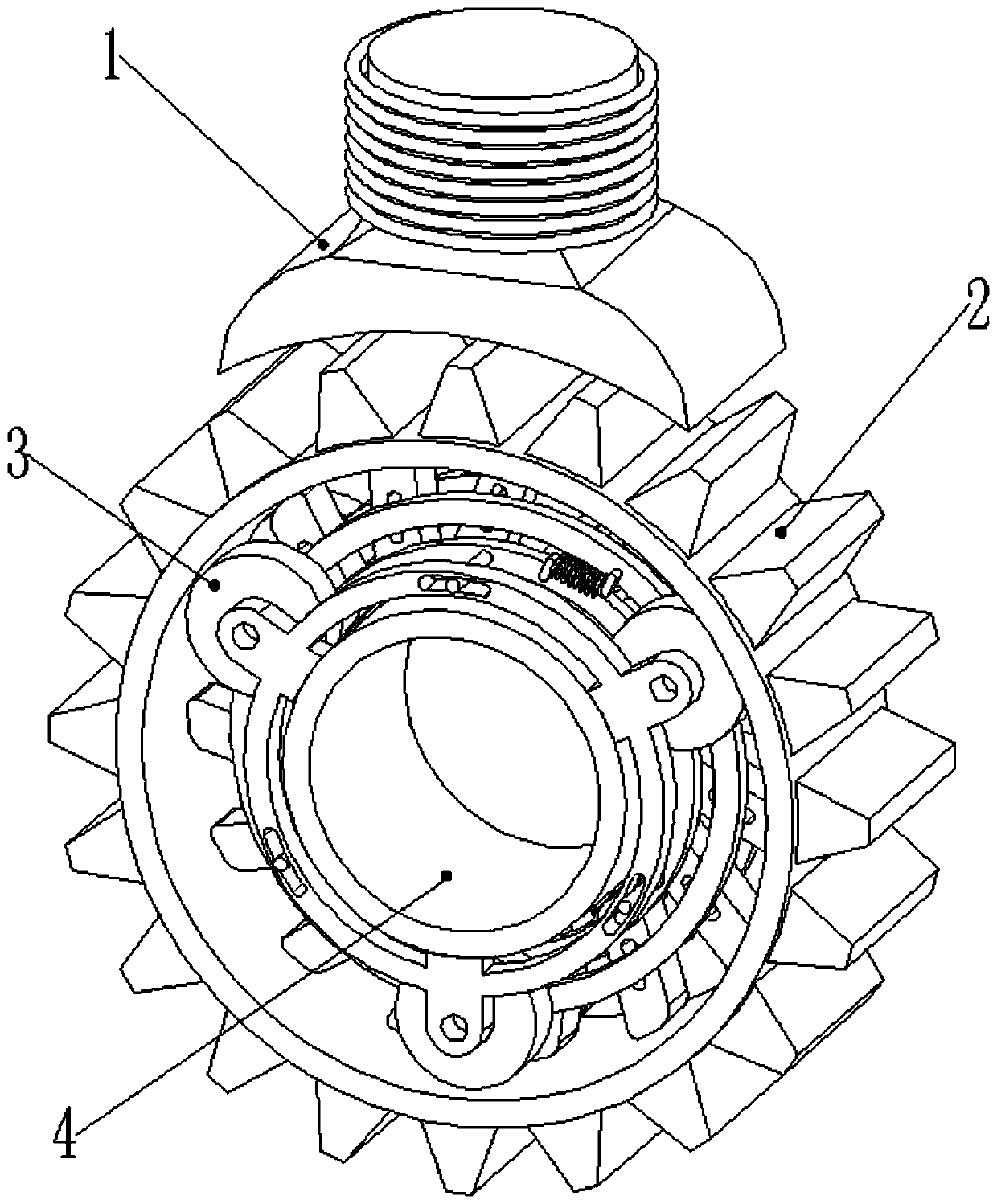

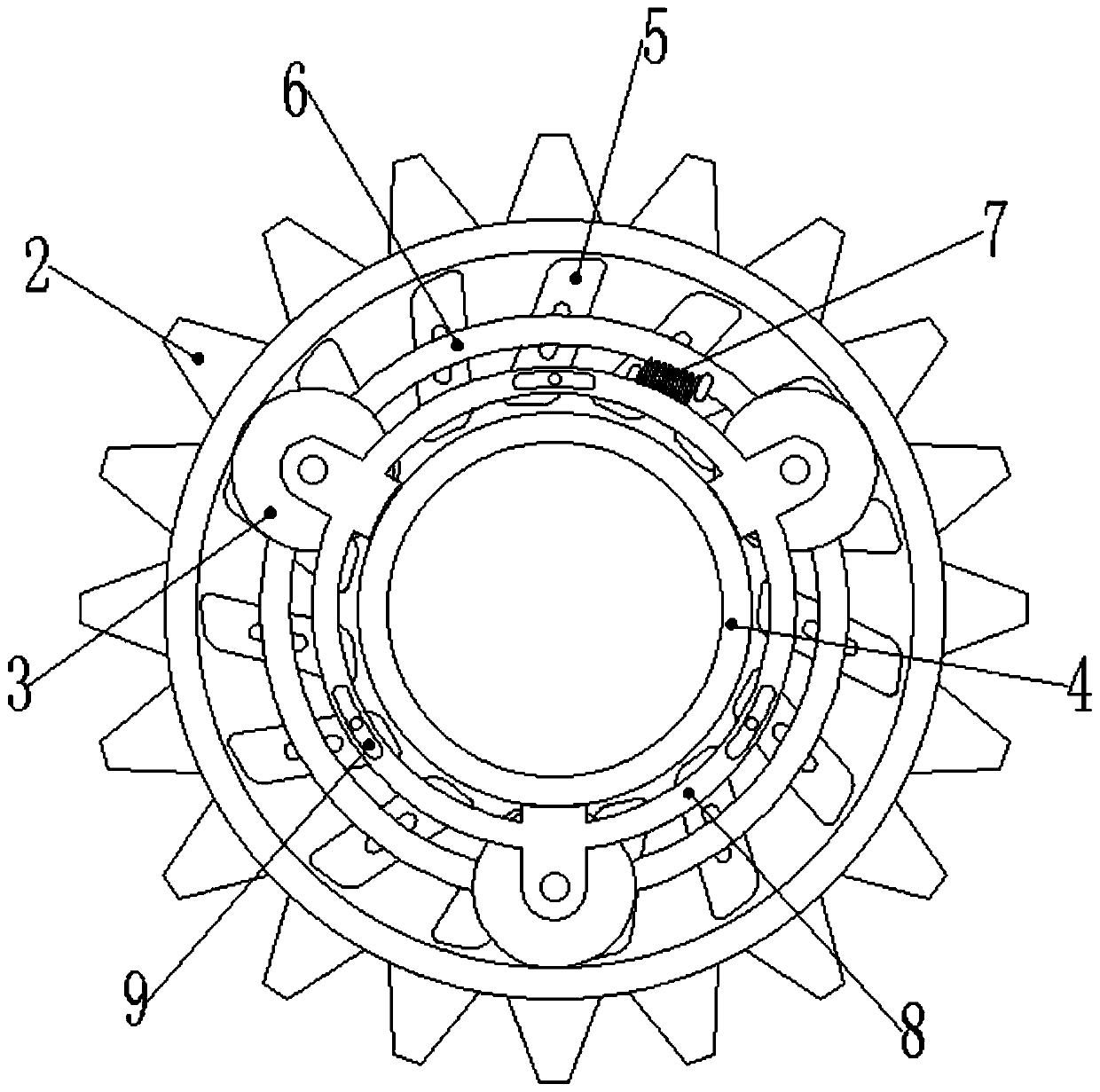

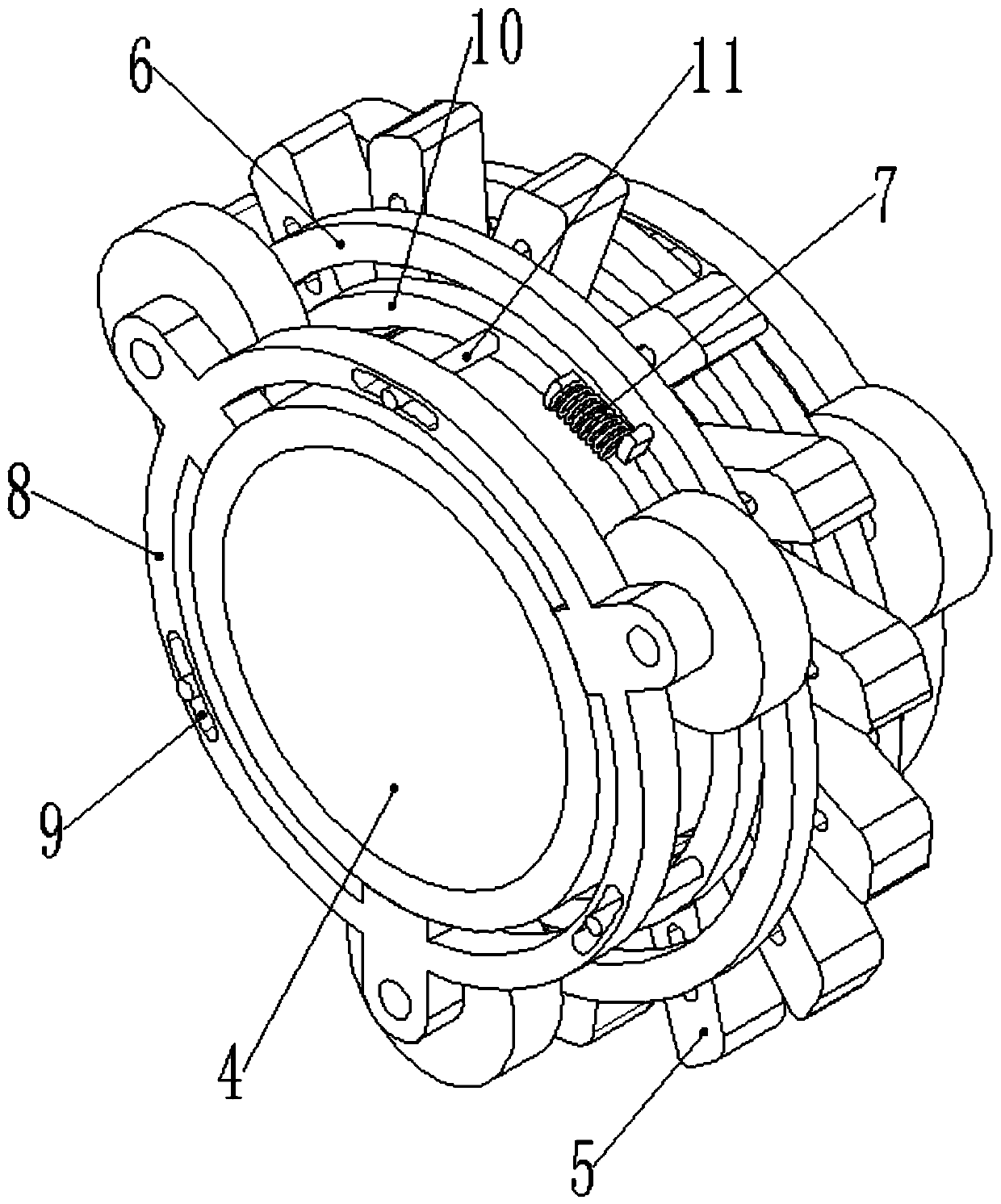

[0028] Such as Figure 1-4 The automatic transmission shown includes an electromagnetic device 1, a round wheel 4 for connecting with the power end, a gear 2 for connecting with the load end, a roller 3, an inclined block 5, a support assembly, a limit assembly and a linkage assembly ;

[0029] The electromagnetic device 1 is arranged on the outer circumference of the gear 2 at a distance from the gear 2 and the magnetic field generated by the electromagnetic device 1 is a non-uniform magnetic field. The closer the electromagnetic device 1 is, the greater the magnetic induction intensity and the corresponding magnetic force.

[0030] The center of the gear 2 is provided with an installation through hole, the round wheel 4 is arranged in the installation through hole, and an annular gap is reserved between the inner peripheral surface of the installation through hole; the round wheel 4 is fixed with a support assembly, and multiple rollers 3 Rotate and install on the support assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com