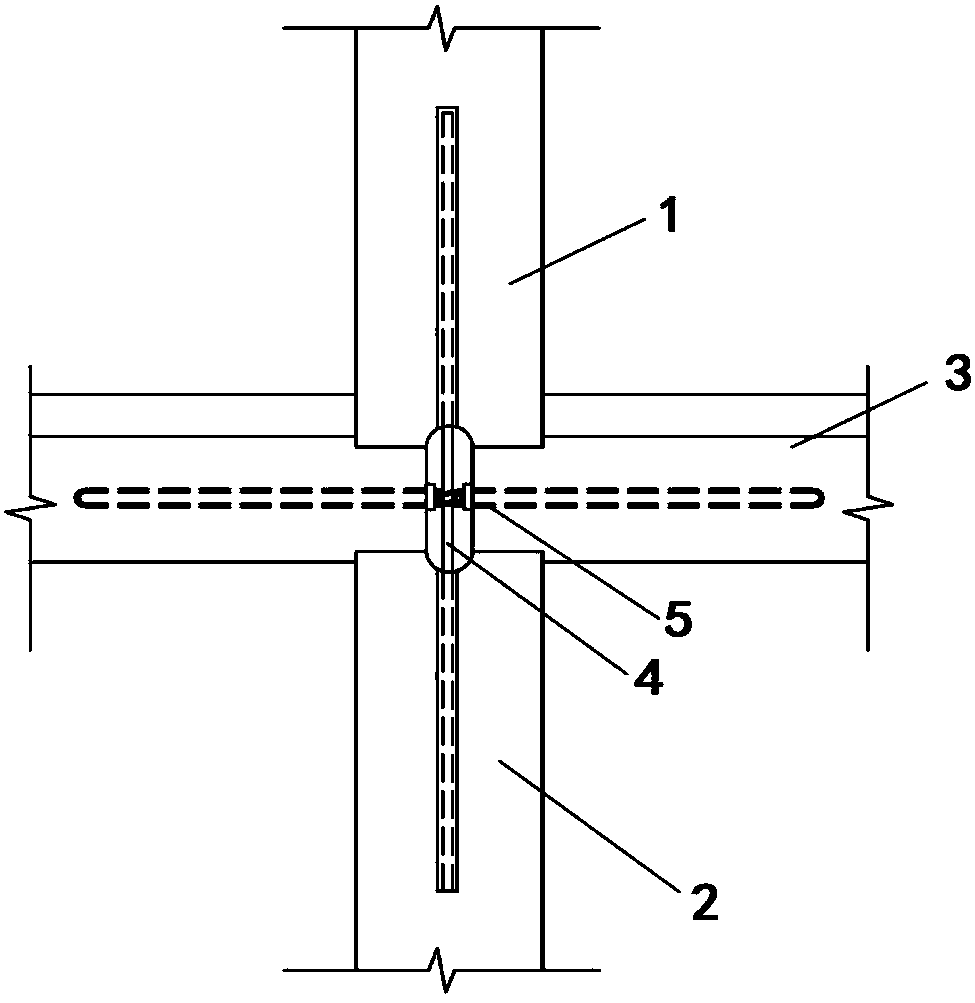

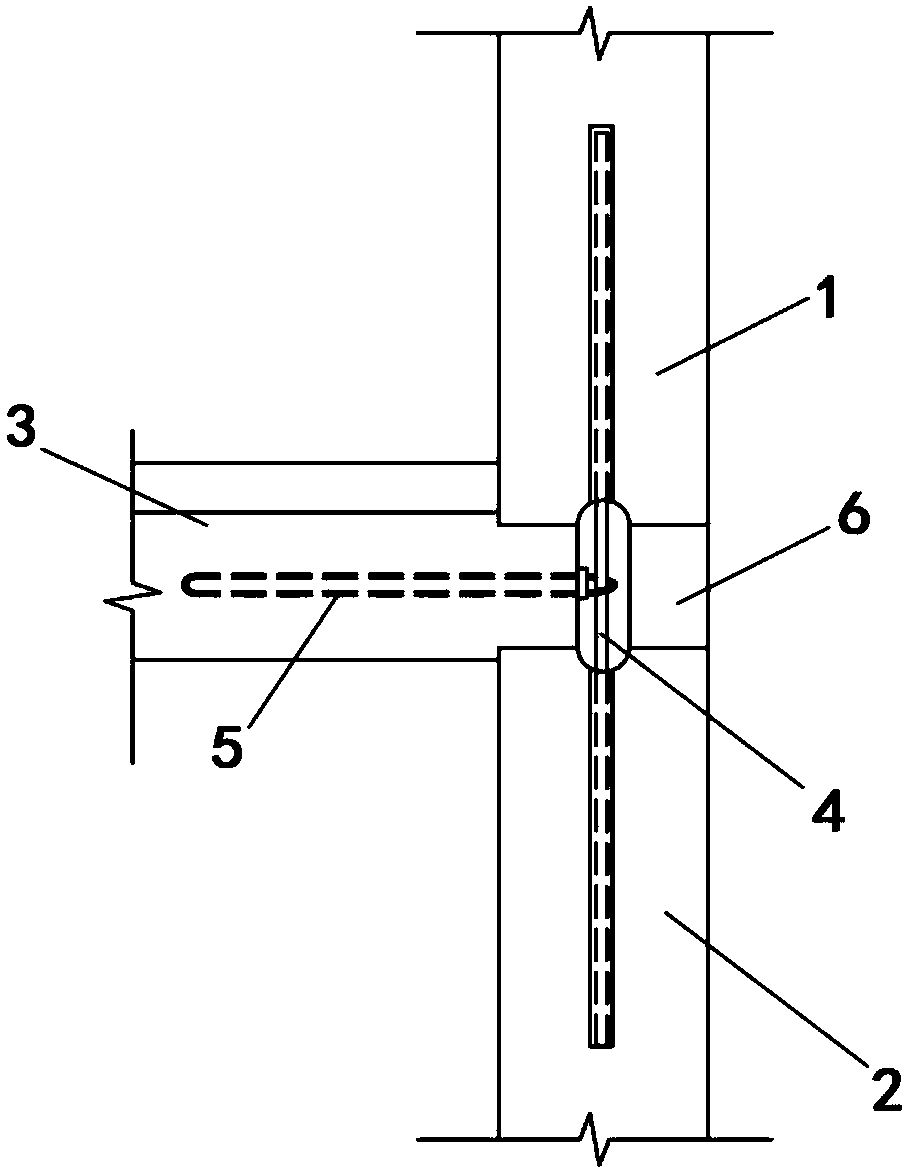

Plate-type prefabricated building floorslab and wallboard combining system

A prefabricated, wall panel technology, applied in construction, building structure, etc., can solve the problems of high cost, complex structure, easy penetration, etc., and achieve the effect of easy operation and promotion, fast and safe installation, and easy factoryization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] During construction, insert steel bars into the reserved holes of the wall panels and pass through the pull rings, so that the floor and wall panels engage up and down, and pump high-strength cement to fill the gaps through the high-level reserved grouting holes to form a floor-wall panel connection system for slab-type prefabricated buildings. , and form the panel installation of the overall structure according to the installation requirements of the panel assembly system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com