Rove vertical transmission feeding and spinning device and method

A technology of roving and clutch device, applied in the field of spinning, can solve the problems of low cost of transformation, poor evenness of yarn evenness, and inability to control fibers well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

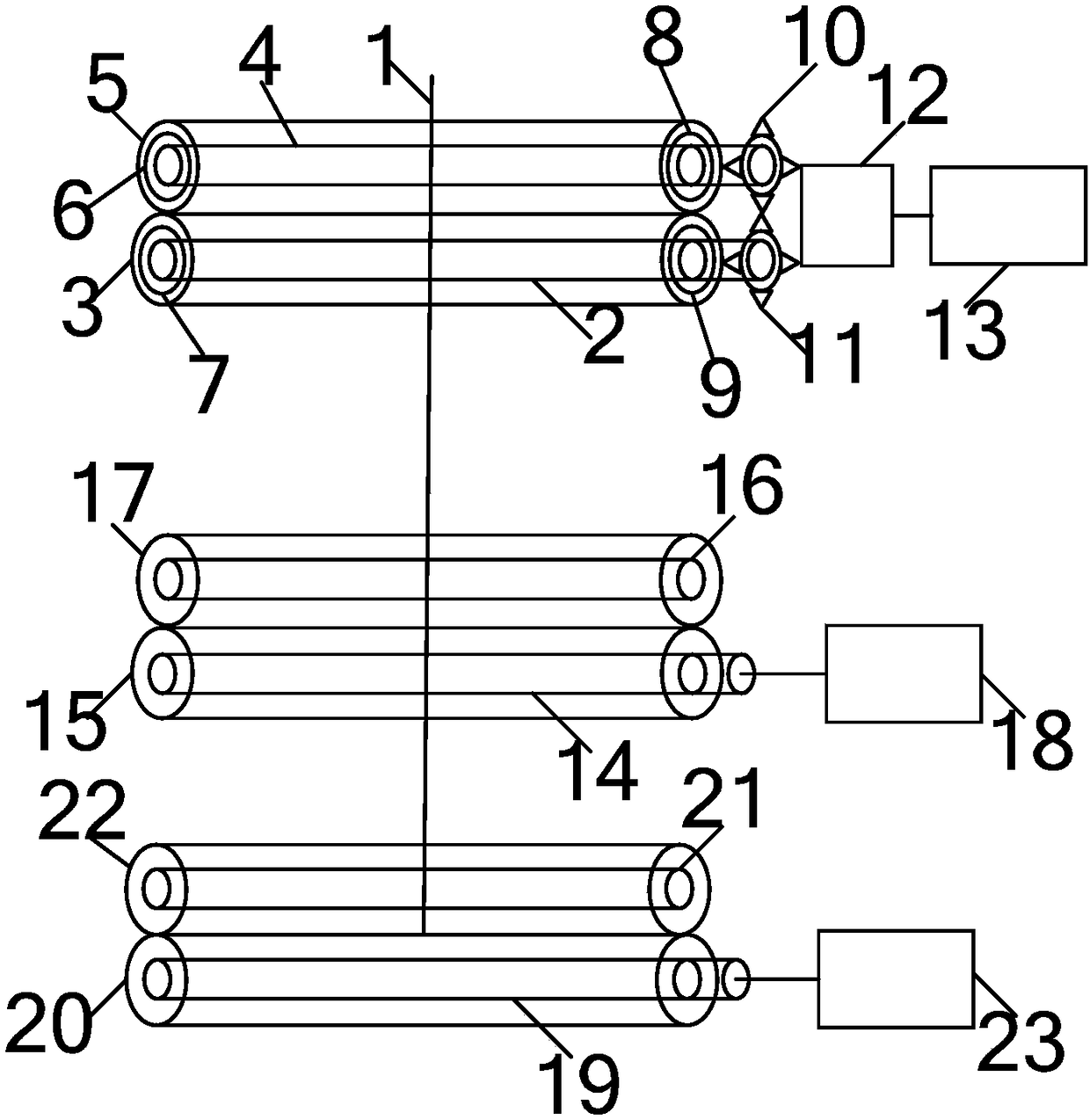

[0017] like figure 1 Shown is a roving feeding spinning device with up and down transmission, including a rear draft roller pair composed of a rear roller and a rear rubber roller, a middle draft roller pair composed of a middle roller and a middle rubber roller, a front roller and a front rubber roller. The front drafting roller pair consists of rollers.

[0018] The rear roller includes a rear roller shaft 2, which is a solid cylindrical structure, and a rear roller sleeve 3 is sleeved on the rear roller shaft 2 on each spindle position, and the left and right ends of the rear roller sleeve 3 respectively pass through the lower left bearing 7 and the lower right bearing 9 are connected with the back roller shaft 2, the lower left bearing 7 and the lower right bearing 9 are release bearings, and the lower left bearing 7 and the lower right bearing 9 are jointly controlled by the first switch to be in an engaged state or in a separated state. When the lower left bearing 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com