An anti-slip device for climbing and an anti-slip Mecanum wheel capable of climbing

An anti-skid device and anti-skid technology, applied in the directions of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of insufficient climbing ability, difficult to solve the problem of Mecanum wheel slip, difficult to climb and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

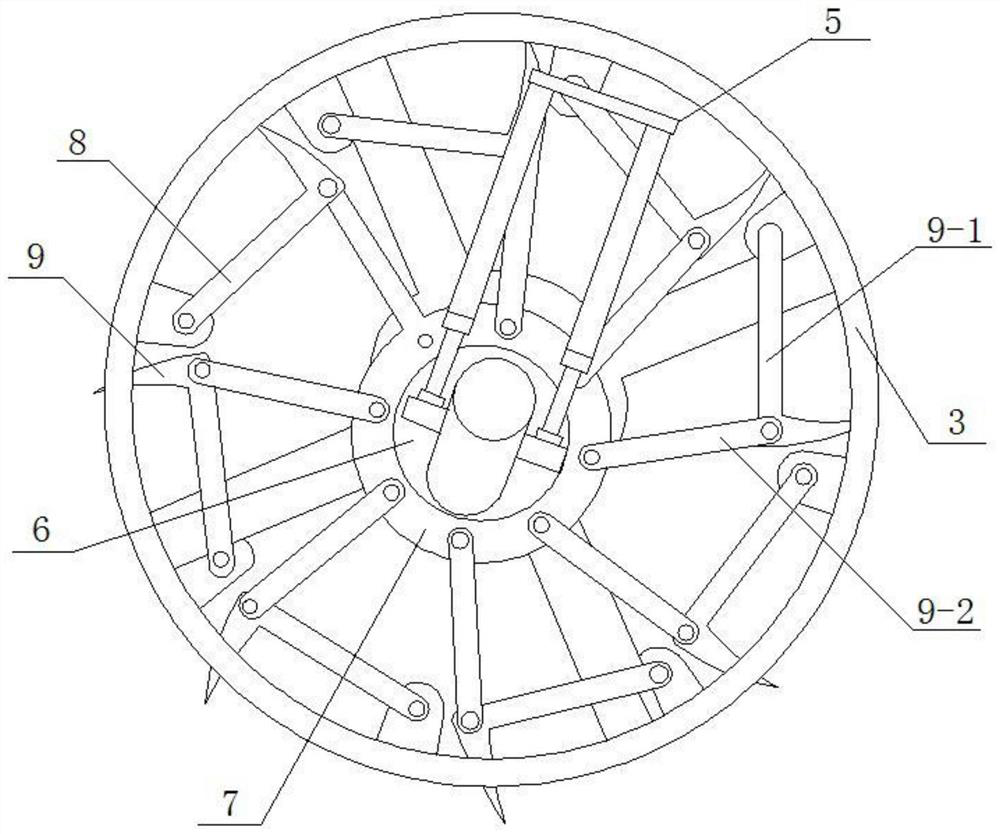

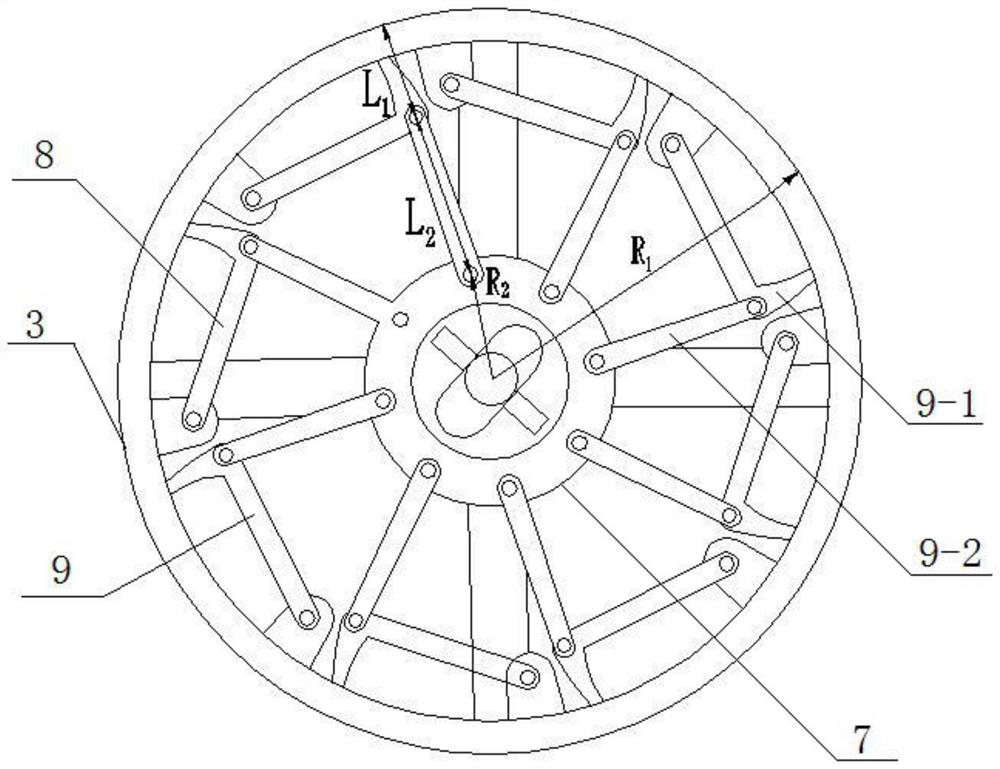

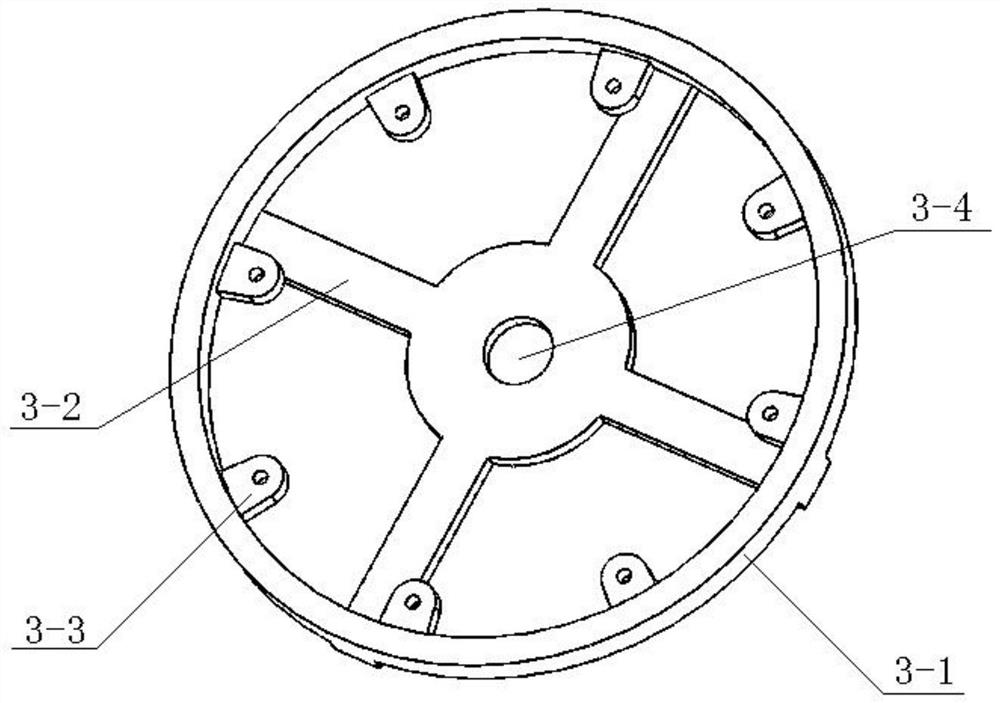

[0031] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 13 , Figure 14 with Figure 15 Describe this embodiment, this embodiment includes ring frame 3, side cover 4, hydraulic pressure rod 5, eccentric connector 6, connecting ring 7, active plow claw 8 and a plurality of passive plow claws 9, and connecting ring 7 comprises circular ring The main body 7-1 and the pole 7-2, the pole 7-2 is arranged on the outer wall of the ring body 7-1 and the two are fixed and connected as one, the connecting ring 7 is inside the ring frame 3 and the two are at the same time. Shaft arrangement, the active plow claw 8 and a plurality of passive plow claws 9 are arranged between the connecting ring 7 and the ring frame 3 along the circumferential direction of the ring frame 3, and one end of the active plow claw 8 is hinged to the support rod 7-2 , the other end of...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination figure 1 , figure 2 , Figure 8 with Figure 9 Illustrate this embodiment, each passive plow claw 9 comprises gripper 9-1 and connecting rod 9-2, and one end of passive plow claw 9 is the gripping end, and the other end of passive plow claw 9 is the connection end, and passive plow claw 9 The connecting end of the connecting rod is hinged with the ring frame 3, one end of the connecting rod 9-2 is hinged on the passive claw 9, and the other end of the connecting rod 9-2 is hinged on the ring body 7-1, and the structure of the active claw 8 is the same as The structure of gripper 9-1 is the same.

[0038] In this embodiment, the gripper 9-1 includes a gripping head 9-1-1 and a handle 9-1-2, and one end of the gripping head 9-1-1 is a tip for gripping the ground, thereby assisting the Mecanum wheel body 1 To improve the grip, the other end of the gripping head 9-1-1 is fixedly connected to one end of the handle 9-1-2, and...

specific Embodiment approach 3

[0039] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 8 with Figure 9 To illustrate this embodiment, a plurality of grooves are processed on the outer edge of the ring frame 3 , one groove is correspondingly provided on the active claw 8 , and one groove is correspondingly arranged on each passive claw 9 . The setting of the groove is to facilitate the passage of the active coulter 8 or the passive coulter 9 . Other structures not mentioned are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com