Detecting method, device and system for cutting precision of laser cutter

A laser cutting machine, precision detection technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of time-consuming, affecting the assembly efficiency of laser cutting machines, and achieve the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

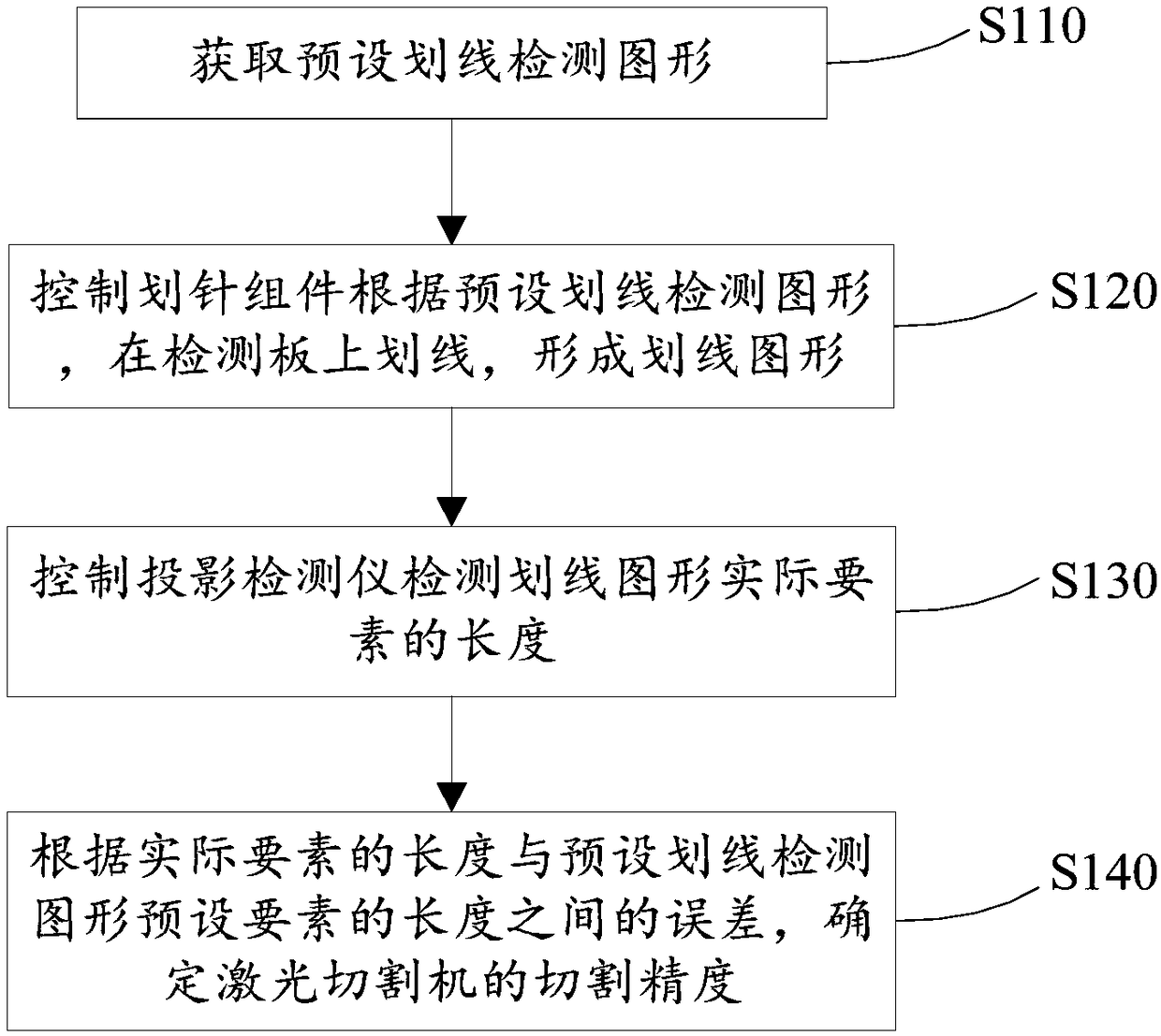

[0064] An embodiment of the present invention provides a method for detecting cutting accuracy of a laser cutting machine, combining figure 1 As shown, the laser cutting machine cutting accuracy detection method includes:

[0065] S110: Acquiring preset streak detection graphics.

[0066] Specifically, a preset line detection pattern is drawn on the software, and the predetermined line detection pattern may be one or more squares and / or one or more figures. The square can be various figures such as square, rectangle, rhombus, polygon, trapezoid, and the like.

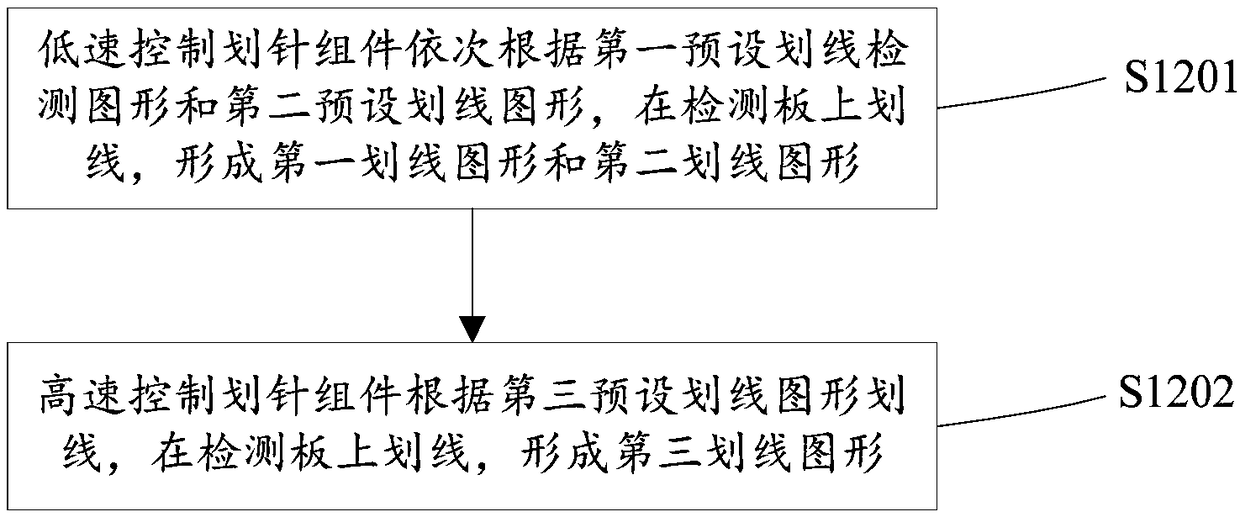

[0067] S120: Control the scribing needle assembly to draw lines on the detection board according to the preset scribing detection pattern to form a scribing pattern; the scribing needle assembly is movably installed on the gantry frame and moves along the gantry frame; the detection board is set on the laser cutting machine bed surface.

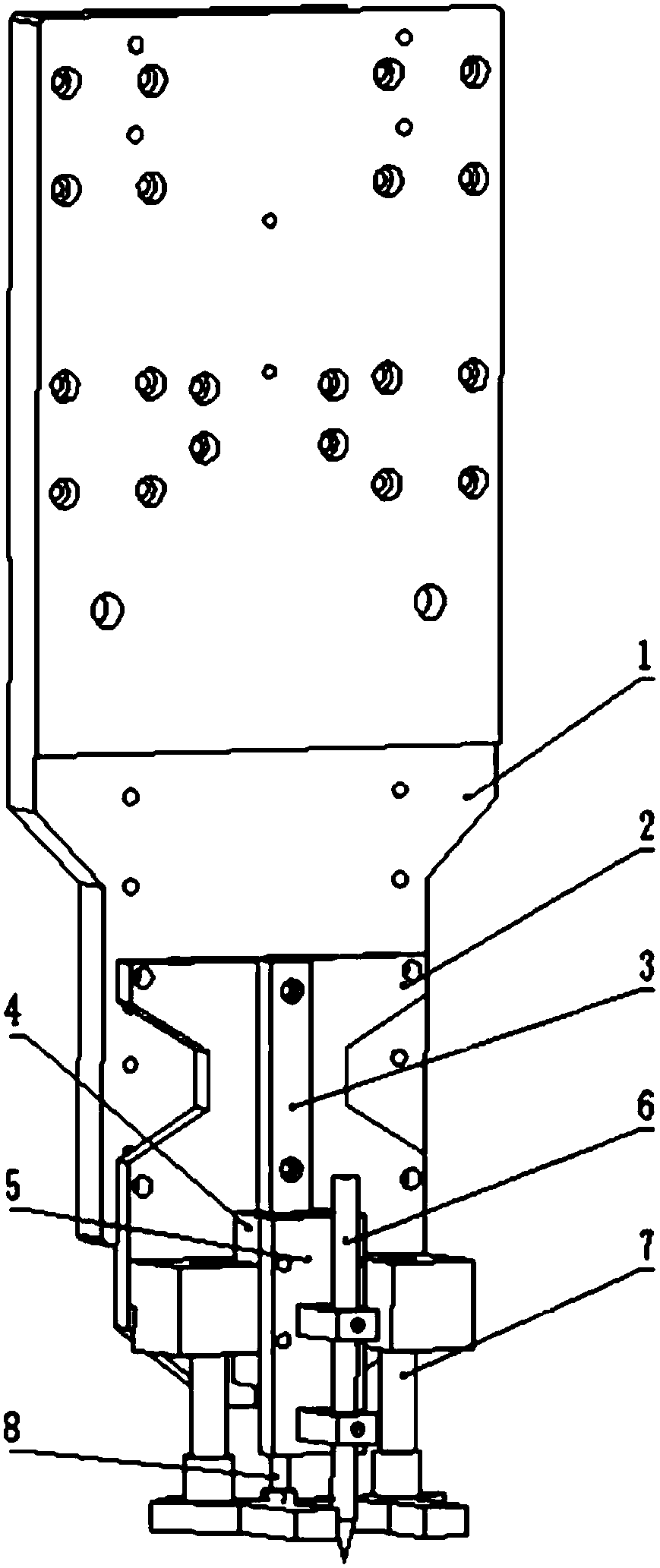

[0068] Specifically, the scribing needle assembly includes a scribing tool and ...

Embodiment 2

[0102] combine Figure 10 As shown, the embodiment of the present invention provides a laser cutting machine cutting accuracy detection device, including: an acquisition unit 710 , a first control unit 720 , a second control unit 730 and a determination unit 740 .

[0103] Wherein, the acquiring unit 710 is configured to acquire a preset line detection pattern;

[0104] The first control unit 720 is used to control the scribing needle assembly to draw lines on the detection board according to the preset scribing detection pattern to form a scribing pattern; the scribing needle assembly is movably installed on the gantry frame, and extends The gantry moves; the detection board is arranged on the bed surface of the laser cutting machine;

[0105] The second control unit 730 is used to control the projection detector to detect the length of the actual elements of the scribing pattern;

[0106] The determining unit 740 is configured to determine the cutting accuracy of the laser...

Embodiment 3

[0123] The third embodiment of the present invention provides a laser cutting machine cutting accuracy detection system, including: a scribing assembly, a bed, a gantry and a controller; the scribing needle assembly is movably installed on the gantry, and The gantry moves; the detection board is arranged on the bed surface of the laser cutting machine; the controller is used to execute the method described in any one of the above embodiments.

[0124] Wherein, the memory may include a high-speed random access memory (RAM, Random Access Memory), and may also include a non-volatile memory (non-volatile memory), such as at least one disk memory.

[0125] Wherein, the memory is used to store a program, and the processor executes the program after receiving an execution instruction, and the method performed by the device for stream process definition disclosed in any of the above-mentioned embodiments of the present invention can be applied to the processor , or implemented by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com