Tea caddy mouth pressing device

A technology of tea cans and can mouths, which is applied in the field of tea can processing equipment, and can solve the problems of easy danger and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

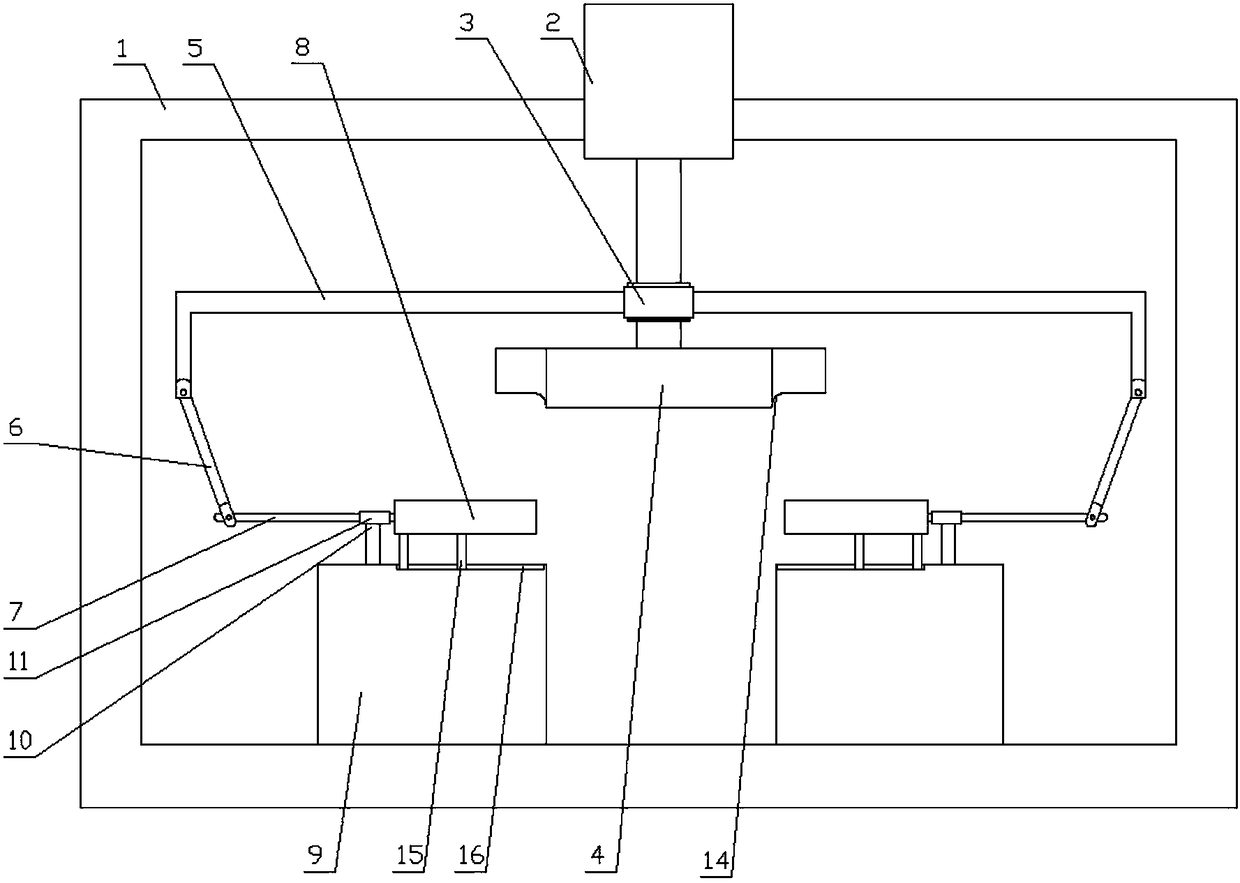

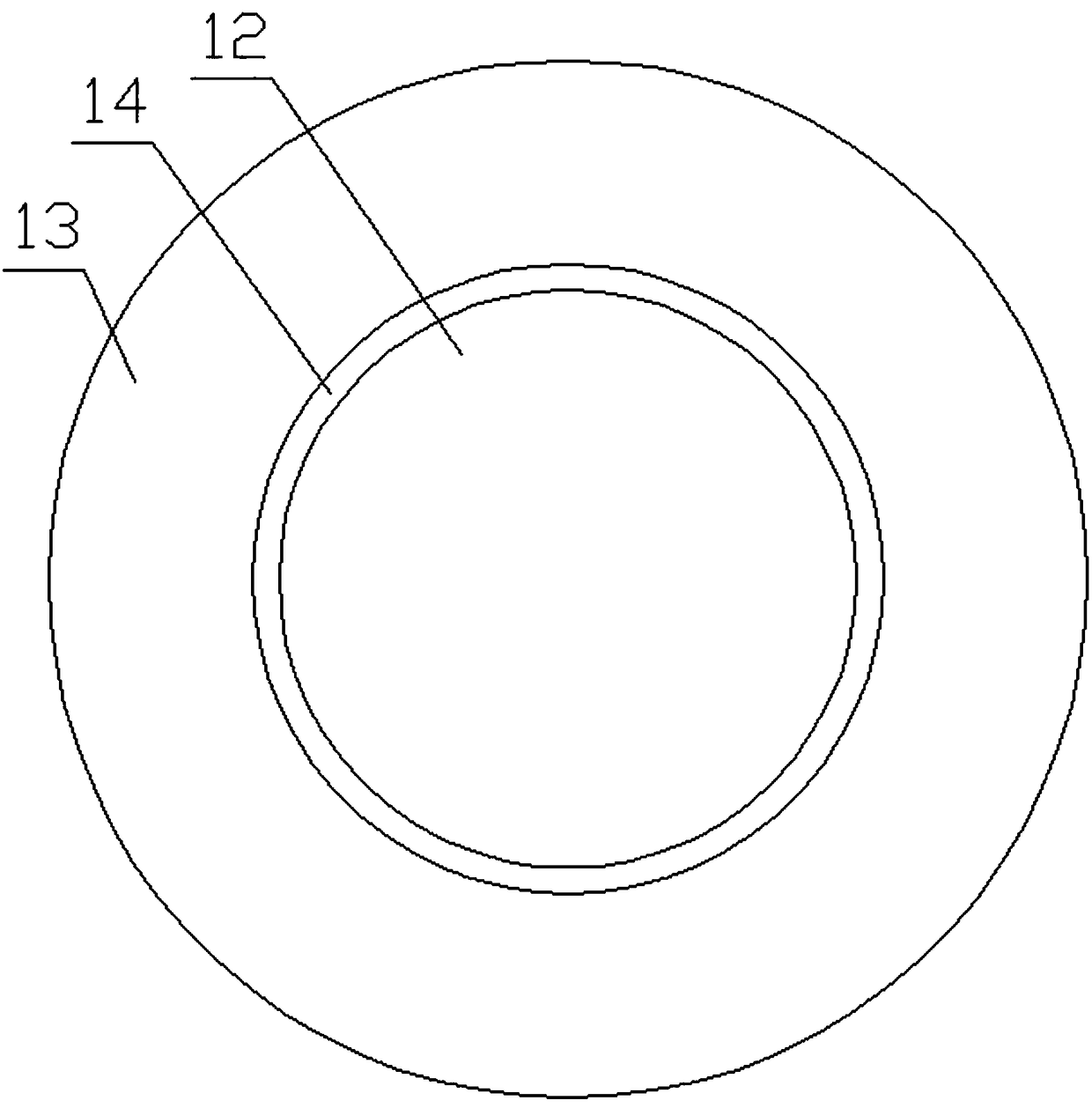

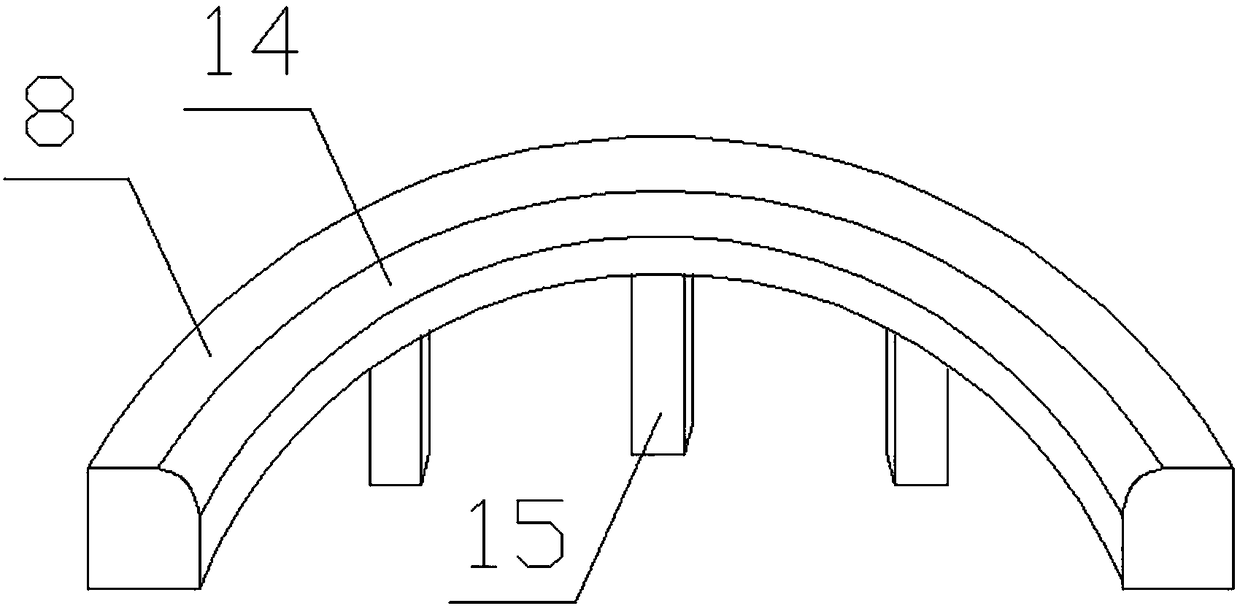

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Figure 1-4 A preferred embodiment of the present invention is described in detail below in conjunction with the accompanying drawings. A tea can pressure mouth device, including a mounting frame 1, the upper end of the mounting frame 1 is provided with a hydraulic cylinder 2, and the lower end of the telescopic rod of the hydraulic cylinder 2 is fixed with a The fixed sleeve 3 and the tank mouth pressure module 4, the fixed sleeve 3 is symmetrically provided with two L-shaped rods 5, the ends of the L-shaped rods 5 are hingedly provided with a deriving rod 6, and the end of the deriving rod 6 A directional slide bar 7 is hinged, and the end of the directional slide bar 7 is fixedly provided with a semicircular clamp 8. The bottom of the installation frame 1 is symmetrically provided with two bases 9, and the upper end of the base 9 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap