Method for loading repaired printed board solder paste of surface mount device

A technology for surface mount devices and printed boards, which is used in printed circuit manufacturing, assembling printed circuits with electrical components, electrical components, etc., to achieve the effect of reducing uncertainty, improving uniformity, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

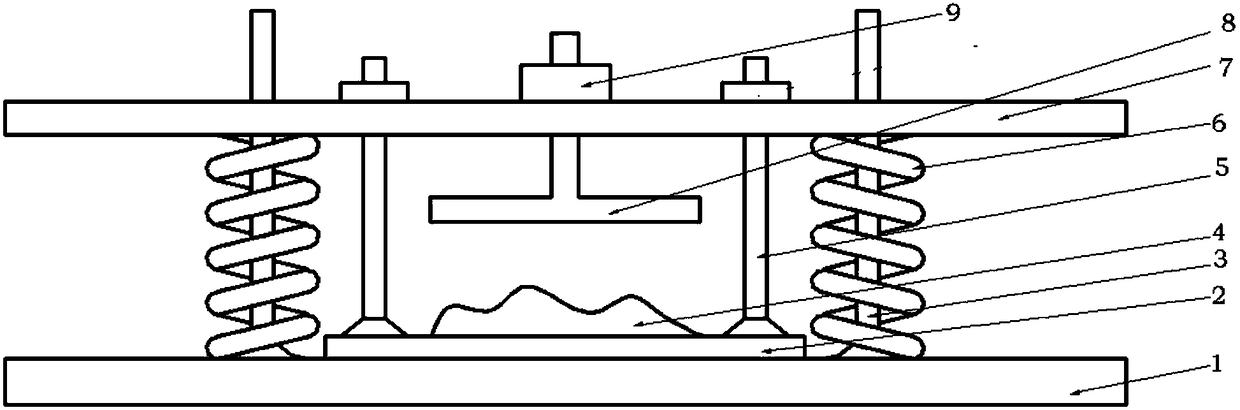

[0019] refer to figure 1 . According to the present invention, the printed board solder paste loading tooling supported on the printed board and formed is passed through the pressing plate 7 with four columns 5 with suction cups and fixed with nuts, and the pressing film plate 8 is screwed on the pressing plate 7 through fastening nuts 9 Above, the spring 6 passes through the spring column 3 and is installed on the pressure plate 7; the steel mesh template 2 is installed on the printed circuit board 1, and is aligned with the pad; the suction cup of the spring column 3 loaded with solder paste is adsorbed on the printed circuit board 1, the suction cup of the column 5 is adsorbed on the stencil template 2; the solder paste 4 is added to the stencil template 2; the pressing plate 7 is pressed, and the spring 6 is compressed, so that the pressing plate 8 on the pressing plate 7 presses the solder paste 4 into the In the mesh hole on the stencil template 2, keep the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com