A metal composite gasket for high temperature proton exchange membrane fuel cell and its application

A metal composite and gasket technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as large thickness deviation, uneven battery compression ratio, leakage, etc., and achieve good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following detailed description and drawings illustrate several exemplary implementation examples of the invention. The specification and drawings are intended to enable those skilled in the art to use and utilize the present invention, but are not intended to limit the protection scope of the present invention in any way. With respect to the disclosed methods, the steps described are exemplary in nature, and thus, the order of the steps is not necessarily required or critical.

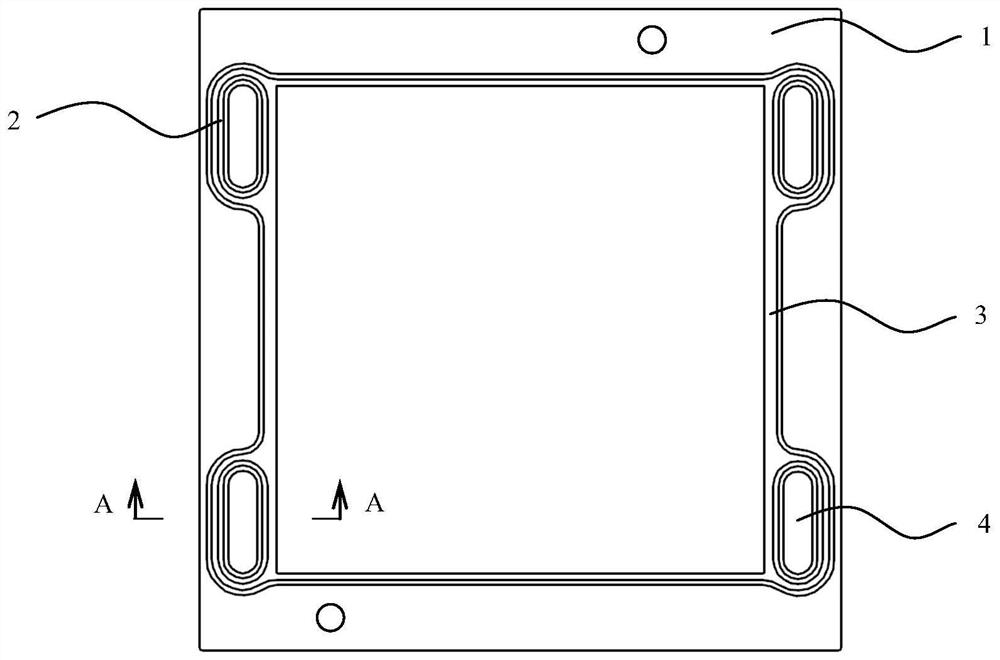

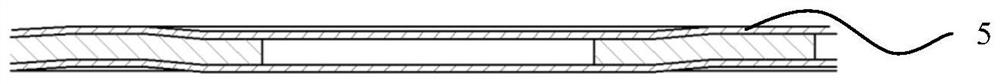

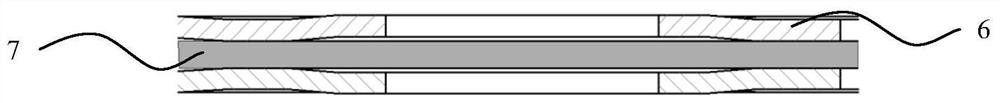

[0032] The metal composite sealing gasket is suitable for high-temperature fuel cell applications. The thickness of the metal base is 0.2mm, the height difference between the protruding surface and the nearest surface of the base is 0.05mm, the thickness of fluorine rubber on one side is 0.1mm, and the size of the positioning hole is Φ4mm. When in use, each metal composite sealing gasket 6 , MEA 7 and pole plate 8 needs to be stacked in sequence by using positioning columns to assemble into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com