Oil injector for parameter test in cylinder of diesel engine and machining method thereof

A fuel injector and internal parameter technology, applied in the direction of internal combustion engine testing, machine/engine, mechanical equipment, etc., can solve the problem that it is difficult to predict the fatigue life of the needle valve body, it is difficult to obtain the mechanical load of the needle valve body, and it is difficult to determine the needle valve Problems such as the temperature value of the body ball head, etc., achieve significant economic benefits and time gains, reduce preparation time and difficulty, and reduce experiment preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

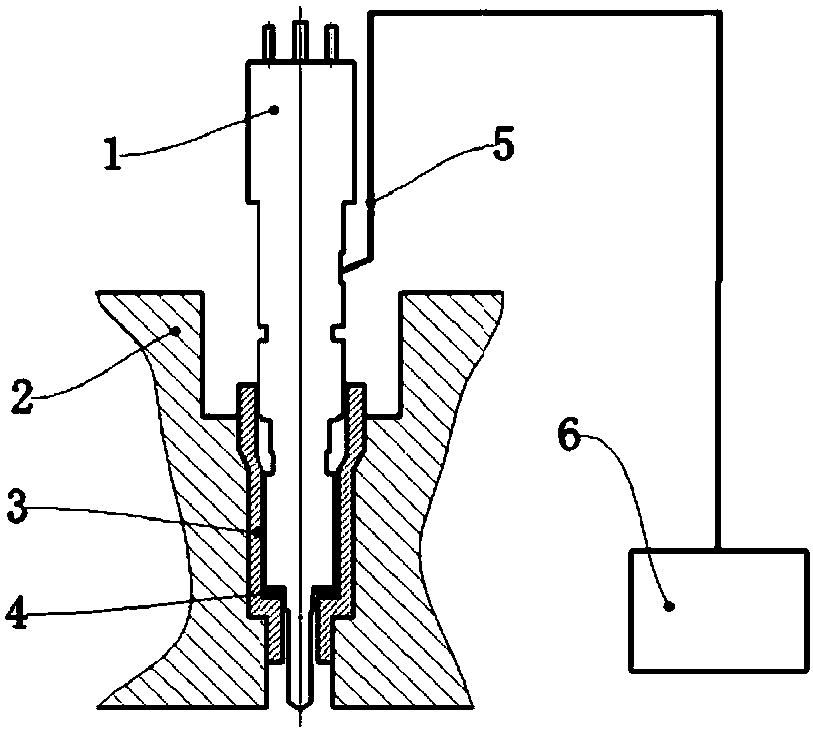

[0084] figure 1 Shown is a schematic diagram of the entire test system. Injector assembly 1, engine cylinder head 2, gasket 4, copper sleeve 3, sensor lead wire 5 and data acquisition equipment 6 are jointly composed of a test system.

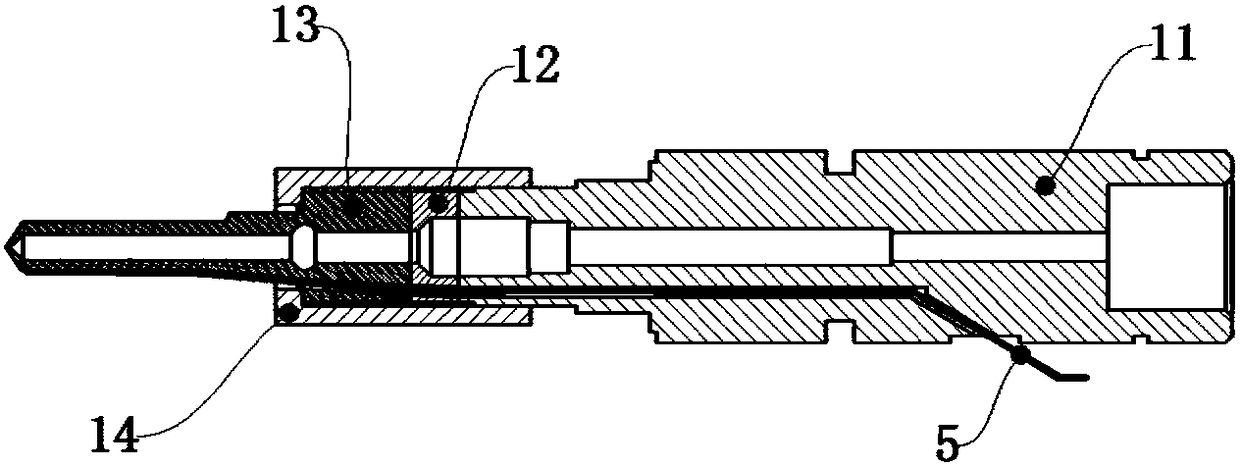

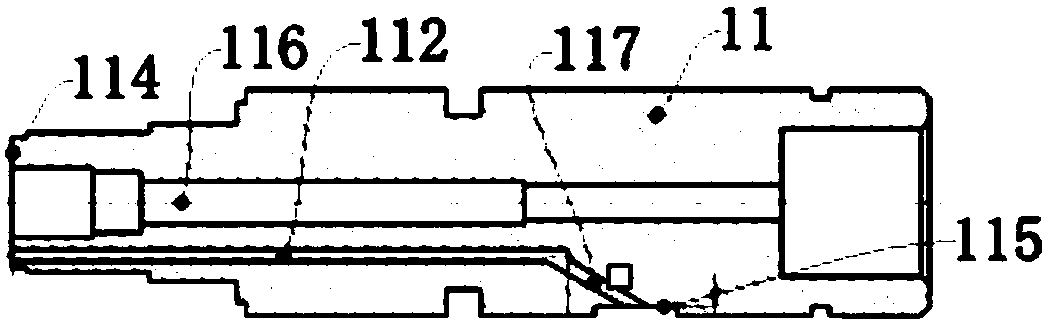

[0085] like figure 2 Assembly schematic shown. The utility model relates to a fuel injector and a matched sensor for testing parameters in a diesel engine cylinder. In the figure, only the modified parts injector body 11, transition block 12, and needle valve body 13 are marked, and other parts in the injector assembly are not indicated in the figure. After normal assembly of the reformed parts, a channel can be formed to facilitate the passage of the sensor or sensor lead wire 5 through the fuel injector assembly, so as to realize the lead wire channel from the inside of the engine cylinder to the outside of the cylinder. In this example, the sensor lead wire 5 is an armored thermocouple, the length of the armor is 50mm, and the diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com