Robot with feedback control function, motion control system, method and medium

A feedback control and robot technology, which is applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of large motion errors, poor precision, and limited robot applications of robots 100, and achieve good compensation effects and high motion accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

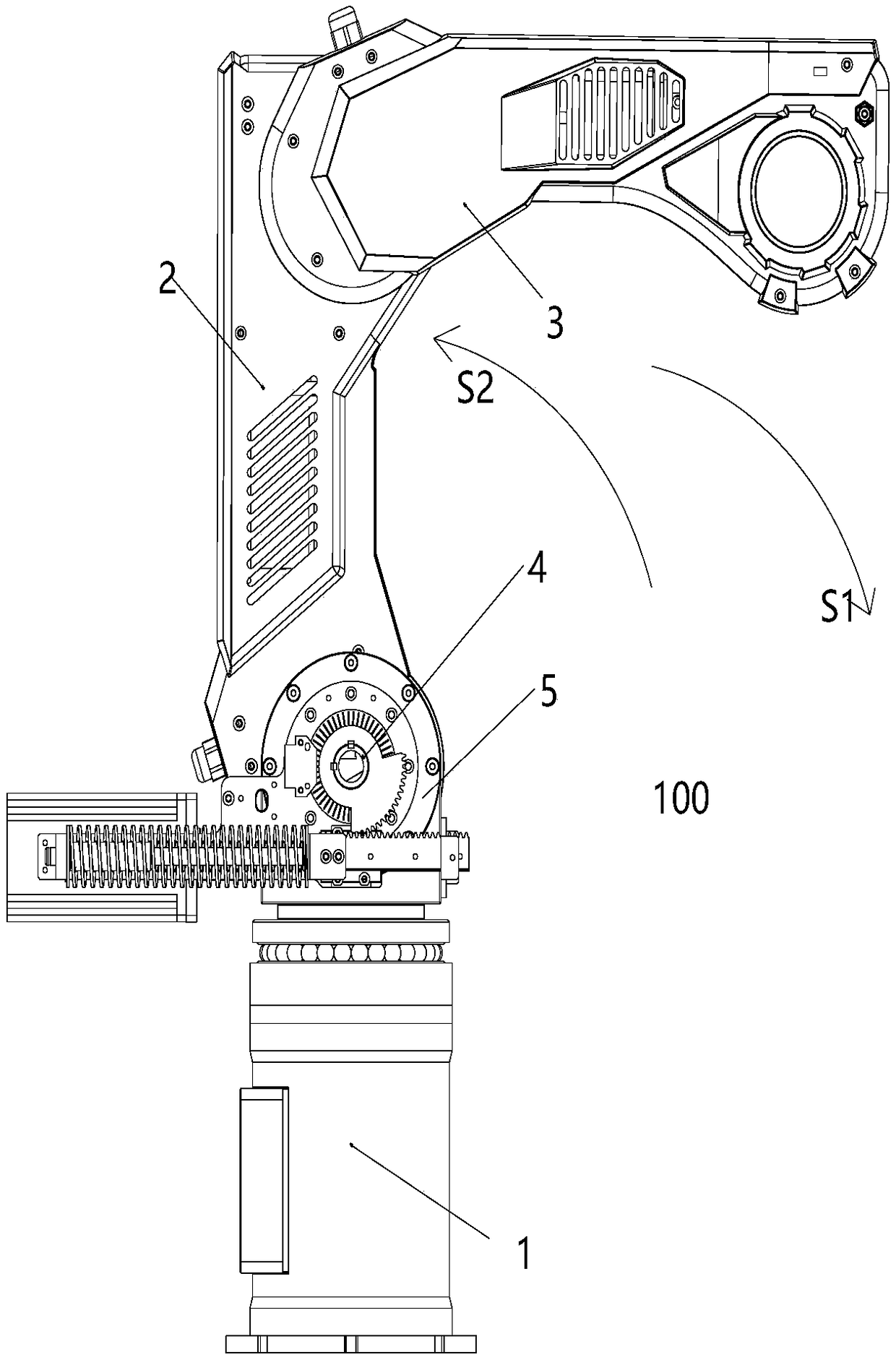

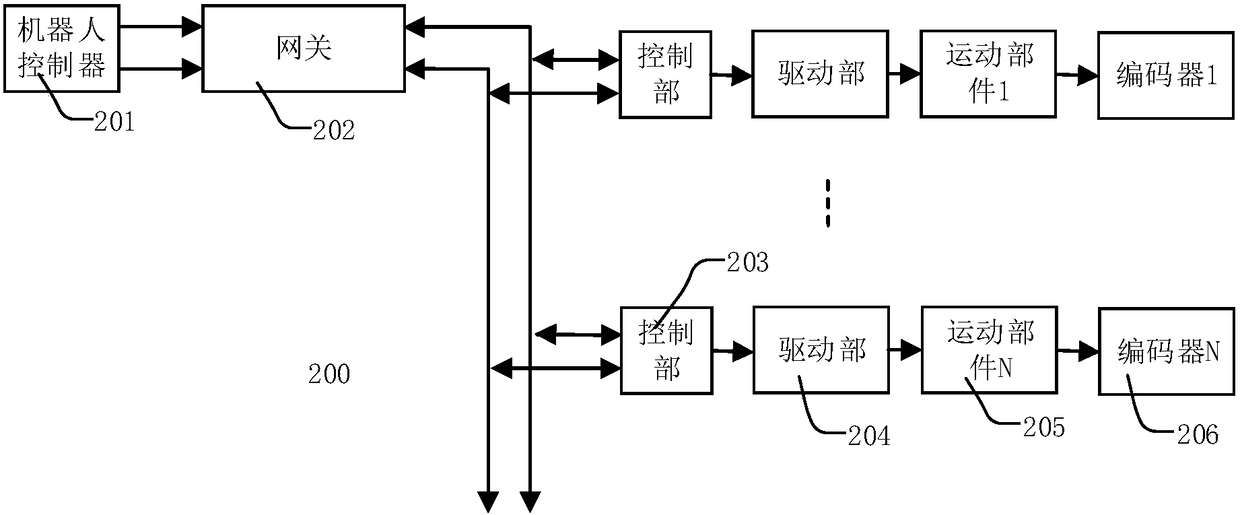

[0100] As a specific example, with reference to the attached figure 1 And attached figure 2 , with figure 1 The structure of the articulated robot 100 is shown, with figure 2 A block diagram of motion control system 200 is shown.

[0101] The robot 100 is a four-joint robot. The robot 100 includes a base 1, a large arm 2, and a small arm 3. The small arm 3 can also be connected with a wrist (attached figure 1 not shown in ), there may be claws on the wrist to realize functions such as grasping objects. For example, Chinese patent application No. 201710381661.7 discloses an object clamping part, which can be installed as a claw on the wrist joint.

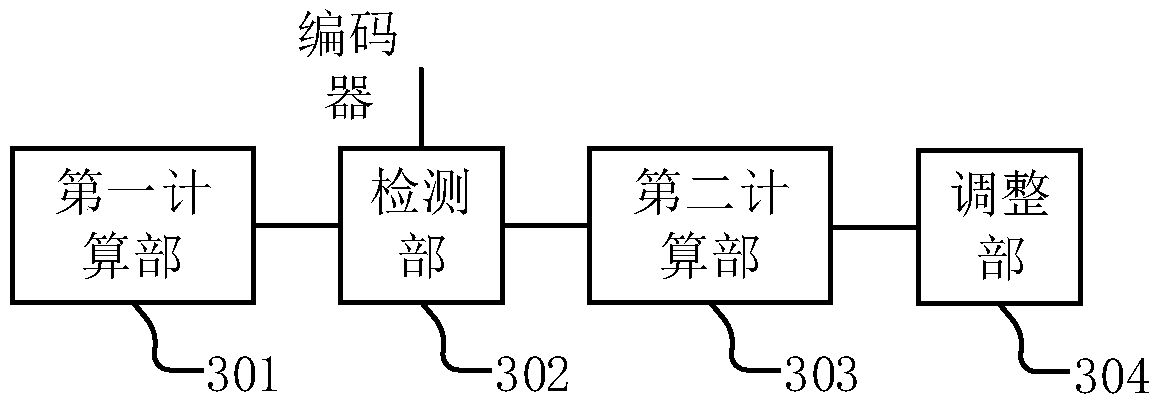

[0102] Each joint of the robot 100 is respectively provided with moving part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com