Outer-rotor high-speed generator using circumferential integral composite permanent magnet structure

A high-speed generator and external rotor technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, winding conductor shape/style/structure, etc., can solve the problem of affecting the reliability of the motor and operating life, irreversible demagnetization rotor strength, large rotor eddy current loss, etc., to solve the effects of severe local heating, increase the rotor speed limit, and reduce core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

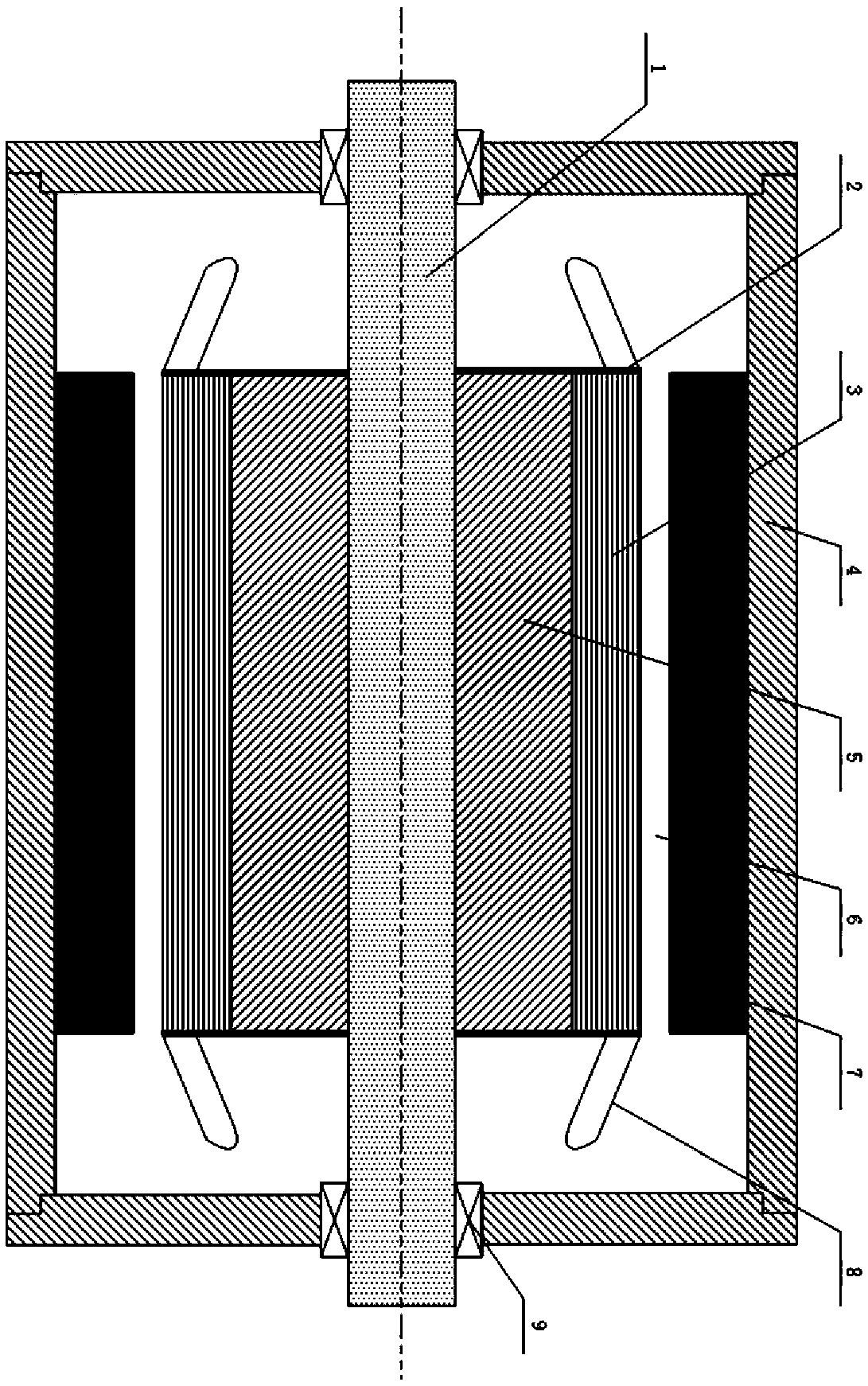

[0032] The specific embodiment: the present invention is specifically described below in conjunction with accompanying drawing:

[0033] An outer rotor high-speed generator adopting a circumferential integral composite permanent magnet structure, characterized in that: the high-speed motor includes an outer rotor and a stator arranged in the outer rotor, and there is a gap between the outer rotor and the stator; the stator includes a stator core 5 and stator winding 3; the stator winding 3 is arranged in the stator slot opened on the outer wall of the stator core 5, and the opening of the stator slot faces the outer rotor;

[0034] The outer rotor includes a rotor core 4 and a hybrid permanent magnet structure 7; the hybrid permanent magnet structure 7 is composed of a plurality of hybrid permanent magnet units, and each hybrid permanent magnet unit is composed of an outer layer of carbon fiber or glass fiber layer 10 and an inner new hybrid permanent magnet material layer 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com