Pin load measurement method and device, measuring instrument and storage medium

A measurement method and technology of nail loading, applied in the field of testing, can solve problems such as difficult to characterize the distribution of nail load, difficult to widely use, difficult manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

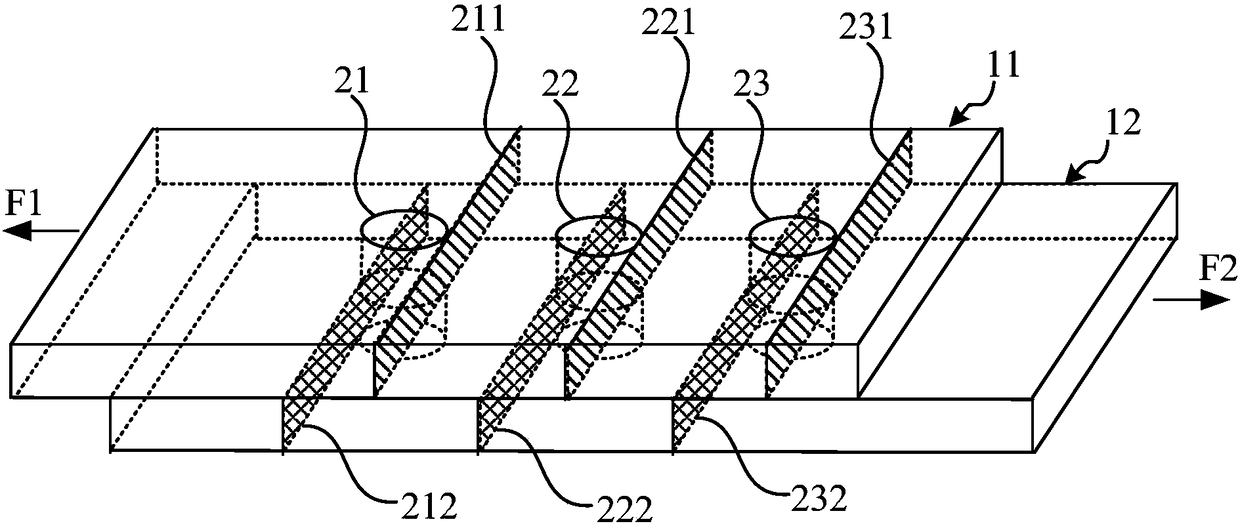

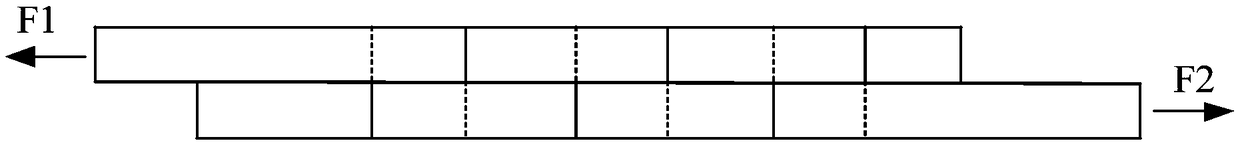

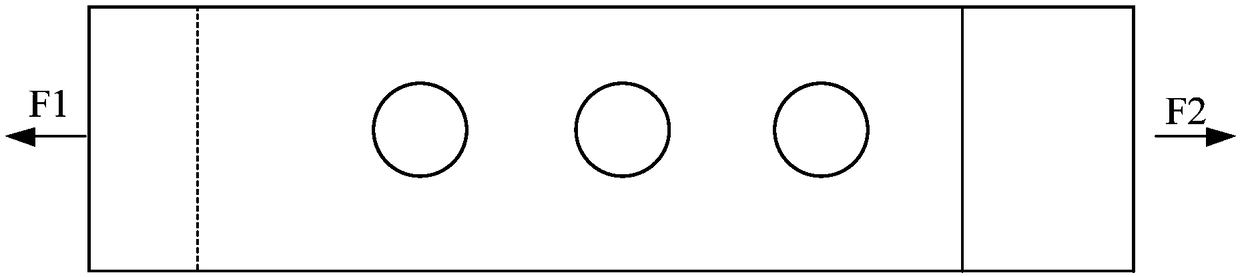

[0032] The composite material connector detected in the embodiment of the present invention includes at least two composite material connecting plates with the same thickness and the same material, each connecting plate is placed in parallel, and adjacent connecting plates are connected by two or more pairs of connecting holes. The hole diameters of the connecting holes are the same. Figure 1A An exemplary three-dimensional structure schematic diagram of a composite material connector is given, which includes two composite material connecting plates 11 and 12 with the same thickness and the same material, wherein the connecting plate 11 and the connecting plate 12 are placed in parallel , and exemplarily gives the situation that two connecting plates are mechanically connected through three pairs of connecting holes—the pair of connecting holes 21 , the pair of connecting holes 22 and the pair of connecting holes 23 . in, Figure 1B for Figure 1A Front view of the connector ...

Embodiment 2

[0053] image 3 It is a schematic flow chart of a nail load measurement method in Embodiment 2 of the present invention. On the basis of the technical solutions of the above-mentioned embodiments, this embodiment further refines the features to improve the technology of the nail load measurement method Program. The method specifically includes:

[0054] S210. When no load is applied to the connecting piece, obtain the three-dimensional position coordinates of the section of the connecting piece tangent to the side walls of each pair of connecting holes to obtain an initial position parameter.

[0055] Further, the step "acquire the cross-section corresponding to the extruded side walls of each pair of connecting holes in the connecting piece when applying loads with opposite directions and the same magnitude to adjacent connecting plates in a direction parallel to the connecting plates The three-dimensional position coordinates of each projection line on the first surface of...

Embodiment 3

[0077] Figure 4 A schematic structural diagram of a nail load measuring device in Embodiment 3 of the present invention, this embodiment is applicable to Figure 1A When the connecting holes in the same or similar connecting pieces of the composite material connecting piece shown in are mechanically connected, the nail load distribution of each pair of connecting holes is measured. The device includes: a first acquisition module 310, a second acquisition module 320 , a deformation ratio determination module 330 and a nail loading value determination module 340 .

[0078] Wherein, the first acquiring module 310 is configured to acquire the projection lines of the section tangent to the side walls of each pair of connecting holes in the connecting piece on the first surface of each connecting plate when no load is applied to the connecting piece. The three-dimensional position coordinates obtain the initial position parameters;

[0079] The second acquisition module 320 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com