A self-controlled intelligent refrigerator system based on time simulation

A smart refrigerator, time simulation technology, applied in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of food spoilage and low intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

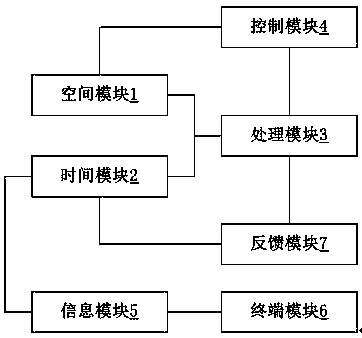

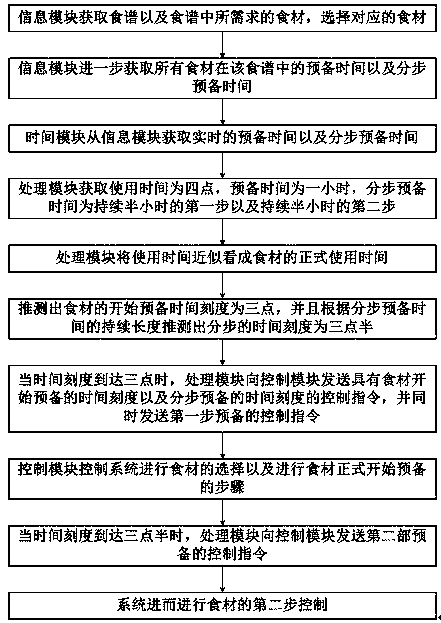

[0026] The reference picture is figure 1 , figure 2 . A self-controlled smart refrigerator system based on time simulation, comprising: a space module 1, a time module 2, a processing module 3, and a control module 4, the space module 1 and the time module 2 are respectively connected to the processing module 3, and the processing Module 3 is connected to the control module 4, the control module 4 is connected to the space module 1, the space module 1 provides food storage space and temporary storage space, and the time module 2 has the preparation time and step-by-step preparation time of food materials. Time, and record the refrigerator use time, the preparation time and the step-by-step preparation time are time intervals, the refrigerator use time is a time scale, the processing module 3 confirms the official use time of the food according to the use time, the processing Module 3 confirms the time scale of food preparation start according to the official use time of foo...

Embodiment 2

[0032] The reference picture is figure 1 , image 3 . With regard to Embodiment 1, the difference of this embodiment lies in:

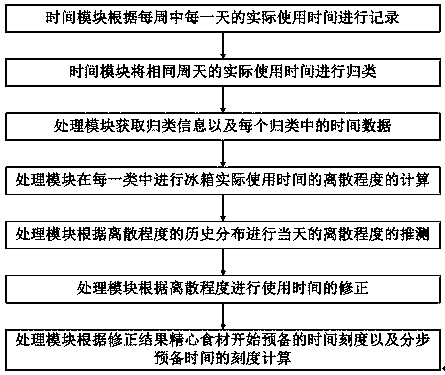

[0033] As a preferred mode of the present invention, the time module 2 is also used to record the actual usage time of the refrigerator every day in a week, and classify the actual usage time of the refrigerator on the same day every week.

[0034] As a preferred mode of the present invention, the processing module 3 obtains the classification of the actual usage time of the refrigerator on the same date every week in the time module 2, and performs the actual usage time of the refrigerator on the same day every week according to the classification. Use the calculation of the degree of dispersion of time, and estimate the usage time of the refrigerator on the current date according to the degree of dispersion corresponding to the current date.

[0035] As a preferred mode of the present invention, the processing module 3 calculates the time scale for...

Embodiment 3

[0038] The reference picture is figure 1 , Figure 4 . With regard to Embodiment 1, the difference of this embodiment lies in:

[0039] As a preferred mode of the present invention, it also includes a feedback module 7, the feedback module 7 is connected to the time module 2 and the processing module 3 respectively, and the feedback module 7 obtains the actual usage time recorded by the time module 2 and The estimation of the usage time of the refrigerator on the current day calculates the estimation accuracy, and the processing module 3 corrects the estimation of the refrigerator usage time according to the estimation accuracy.

[0040] As a preferred mode of the present invention, the time module 2 is also used to record the actual preparation time of the ingredients.

[0041] As a preferred mode of the present invention, the feedback module 7 is also connected to the information module 5, the feedback module 7 obtains the actual preparation time recorded by the time modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com