A low-cost, water-based, fast-drying silver paint

A low-cost, coating technology, applied in the direction of coating, etc., can solve the problems of poor chemical resistance, difficult construction, slow drying speed, etc., and achieve the effect of strong chemical resistance, scientific and reasonable design, and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

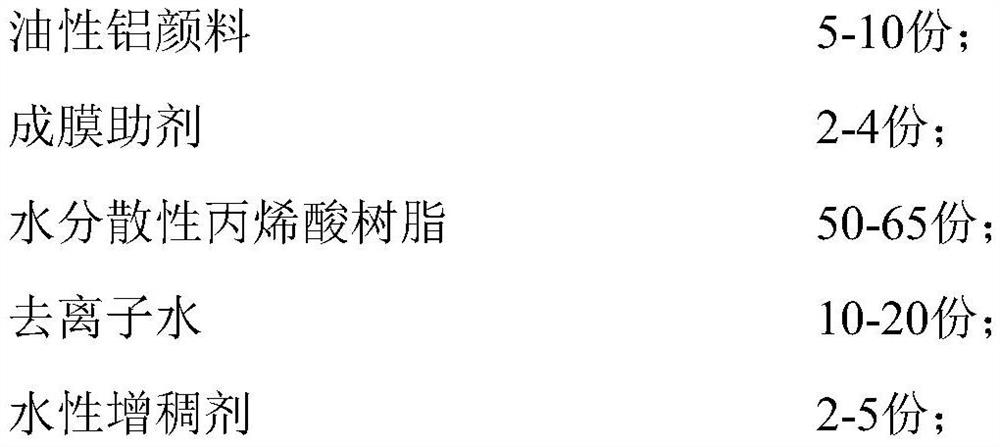

[0025] A low-cost water-based quick-drying silver paint, its innovation lies in: including the following components:

[0026]

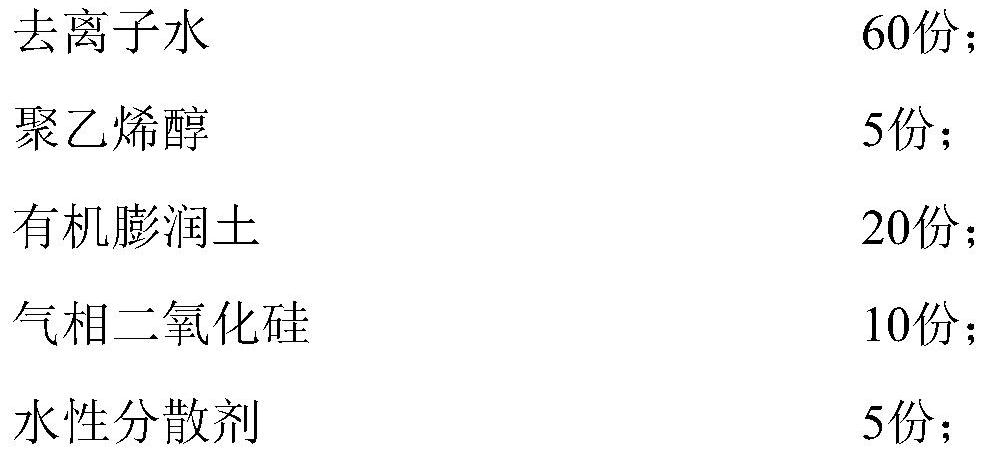

[0027] Described aqueous thickener comprises following components:

[0028]

[0029] The preparation method of described aqueous thickener is:

[0030] (1) add deionized water in the reactor;

[0031] (2) Control the rotating speed of the stirring paddle in the reactor, set it as 500R / min, and add water-based dispersant therein;

[0032] (3) Control the rotating speed of the stirring paddle in the reactor, set it as 1000R / min, add deionized water, polyvinyl alcohol, organobentonite and fumed silica successively in the state of stirring;

[0033] (4) After continuous stirring for 1 hour, the present water-based thickener was obtained.

Embodiment 2

[0035] A low-cost water-based quick-drying silver paint, its innovation lies in: including the following components:

[0036]

[0037] Described aqueous thickener comprises following components:

[0038]

[0039]

[0040] The preparation method of described aqueous thickener is:

[0041] (1) add deionized water in the reactor;

[0042] (2) Control the rotating speed of the stirring paddle in the reactor, set it as 500R / min, and add water-based dispersant therein;

[0043] (3) Control the rotating speed of the stirring paddle in the reactor, set it as 1000R / min, add deionized water, polyvinyl alcohol, organobentonite and fumed silica successively in the state of stirring;

[0044] (4) After continuous stirring for 1 hour, the present water-based thickener was obtained.

Embodiment 3

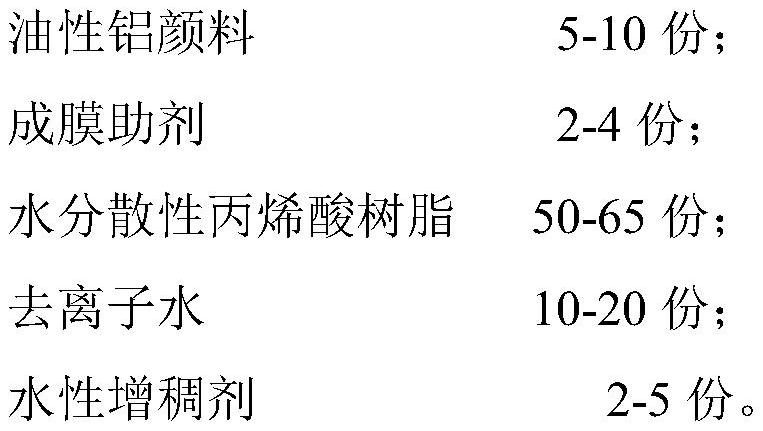

[0046] A low-cost water-based quick-drying silver paint, its innovation lies in: including the following components:

[0047]

[0048] Described aqueous thickener comprises following components:

[0049]

[0050] The preparation method of described aqueous thickener is:

[0051] (1) add deionized water in the reactor;

[0052] (2) Control the rotating speed of the stirring paddle in the reactor, set it as 500R / min, and add water-based dispersant therein;

[0053] (3) Control the rotating speed of the stirring paddle in the reactor, set it as 1000R / min, add deionized water, polyvinyl alcohol, organobentonite and fumed silica successively in the state of stirring;

[0054] (4) After continuous stirring for 1 hour, the present water-based thickener was obtained.

[0055] The water-dispersible acrylic resin in the present invention is an acrylic resin that can be dispersed in water. The water-dispersible acrylic resin used in the embodiment of the present invention is pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com