Preparation process for producing baking-free brick from household garbage incineration furnace slag

A technology for domestic waste incineration and preparation process, which is applied in the field of solid waste resource utilization and building materials, and can solve problems such as secondary pollution, hidden dangers of environmental pollution, and restrictions on the popularization and application of waste incineration technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

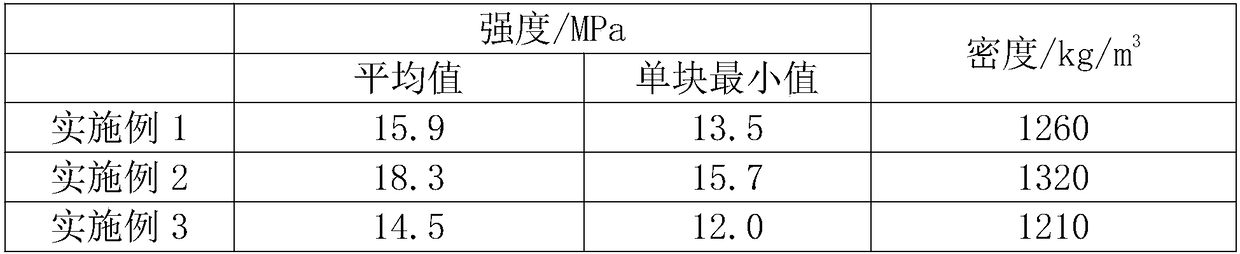

Examples

Embodiment 1

[0016] A preparation process for preparing burn-free bricks by utilizing domestic waste incineration slag, comprising the following steps:

[0017] In the first step, after the domestic waste incinerator slag is manually sorted, crushed, screened, washed with water and magnetically separated, the particle size of the recycled aggregate obtained from the domestic waste incinerator slag is 0-10 mm.

[0018] In the second step, the domestic waste incineration slag regenerated aggregate, mining and mineral processing waste slag and cement generated in the first step are mixed and stirred, and the mass percentage of the domestic waste incineration slag regenerated aggregate, mining and mineral processing waste slag and cement is 55:35:10.

[0019] In the third step, the dry mixture generated in the second step is added with water and stirred evenly, and the mass ratio of the dry mixture to water is 92:8. It is pressed and formed by a hydraulic forming machine, and the pressure is 4...

Embodiment 2

[0022] A preparation process for preparing burn-free bricks by utilizing domestic waste incineration slag, comprising the following steps:

[0023] In the first step, after the domestic waste incinerator slag is manually sorted, crushed, screened, washed with water and magnetically separated, the particle size of the recycled aggregate obtained from the domestic waste incinerator slag is 0-10mm.

[0024] In the second step, the domestic waste incineration slag regenerated aggregate, mining ore dressing waste slag and cement generated in the first step are mixed and stirred, and the mass percentage of the domestic waste incineration slag regenerated aggregate, mining ore beneficiation waste slag and cement is 60:25:15.

[0025] In the third step, the dry mixture generated in the second step is added with water and stirred evenly, and the mass ratio of the dry mixture to water is 90:10. It is pressed and formed by a hydraulic forming machine, and the pressure is 35MPa.

[0026]...

Embodiment 3

[0028] A preparation process for preparing burn-free bricks by utilizing domestic waste incineration slag, comprising the following steps:

[0029] In the first step, after the domestic waste incinerator slag is manually sorted, crushed, screened, washed with water and magnetically separated, the particle size of the recycled aggregate obtained from the domestic waste incinerator slag is 0-10mm.

[0030] In the second step, the domestic waste incineration slag regenerated aggregate, mining ore dressing waste slag and cement generated in the first step are mixed and stirred, and the mass percentage of the domestic waste incineration slag regenerated aggregate, mining ore beneficiation waste slag and cement is 65:27:8.

[0031] In the third step, the dry mixture generated in the second step is added with water and stirred evenly, and the mass ratio of the dry mixture to water is 95:5. It is pressed and formed by a hydraulic forming machine, and the pressure is 40MPa.

[0032] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com