Glue solution saved type pressing device

A saving glue technology, applied in the field of pressing devices, can solve the problems of glue waste, low cleanliness of the working environment, poor glue box effect, etc., to achieve the goal of avoiding glue waste, firm pressing, and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

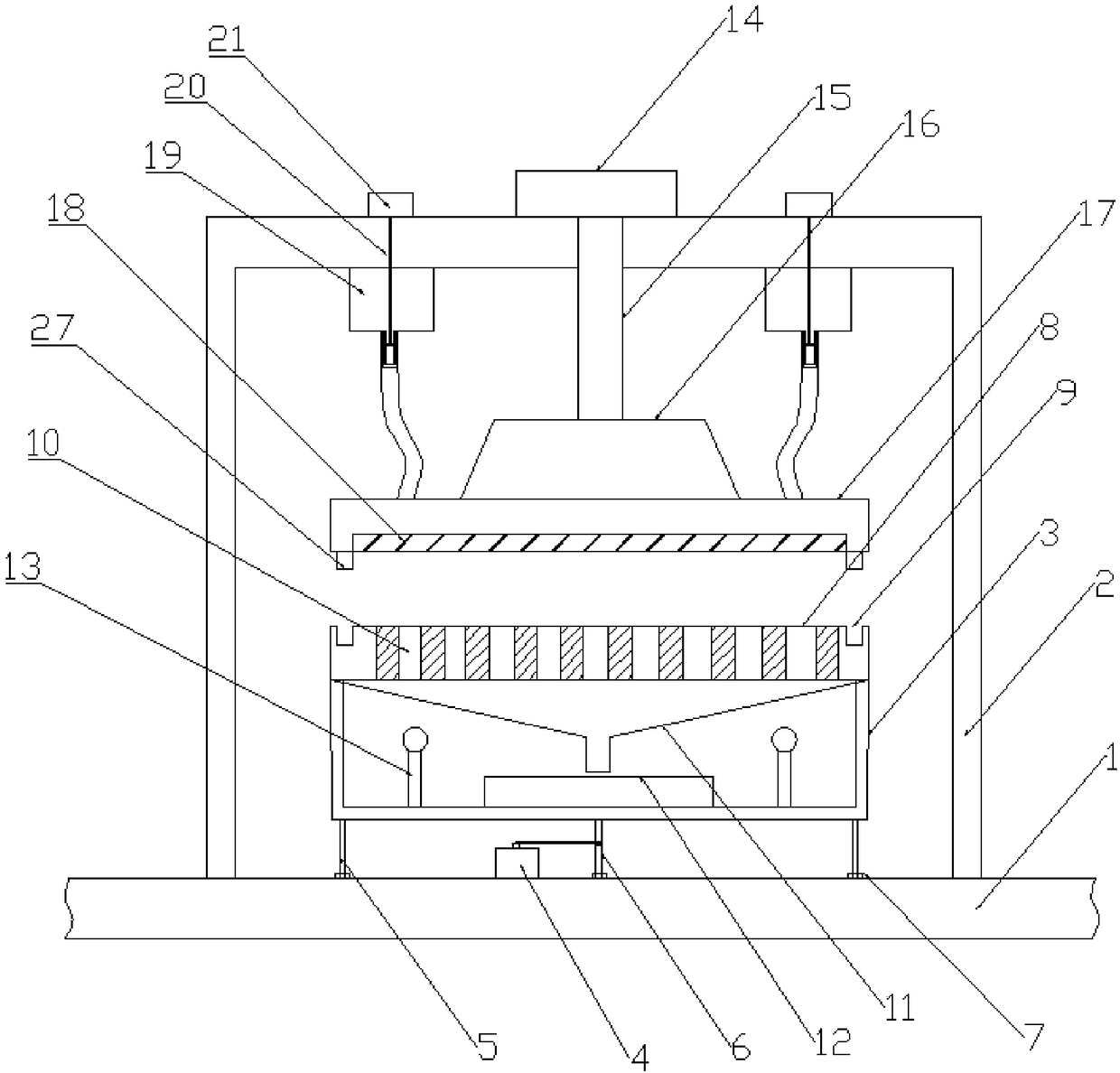

[0026] Such as Figure 1-3 As shown, a glue-saving pressing device includes an operating table 1, and the operating table 1 is provided with a fixed frame 2 and a rotating motor 4,

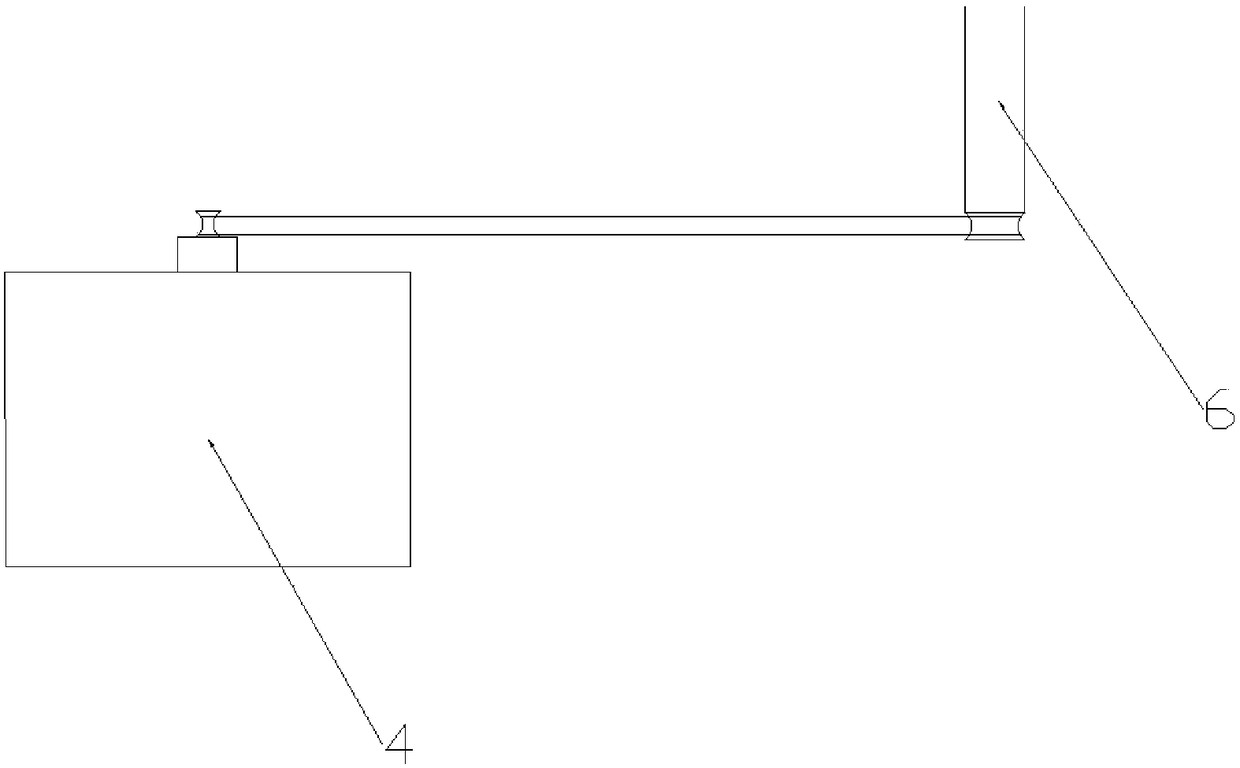

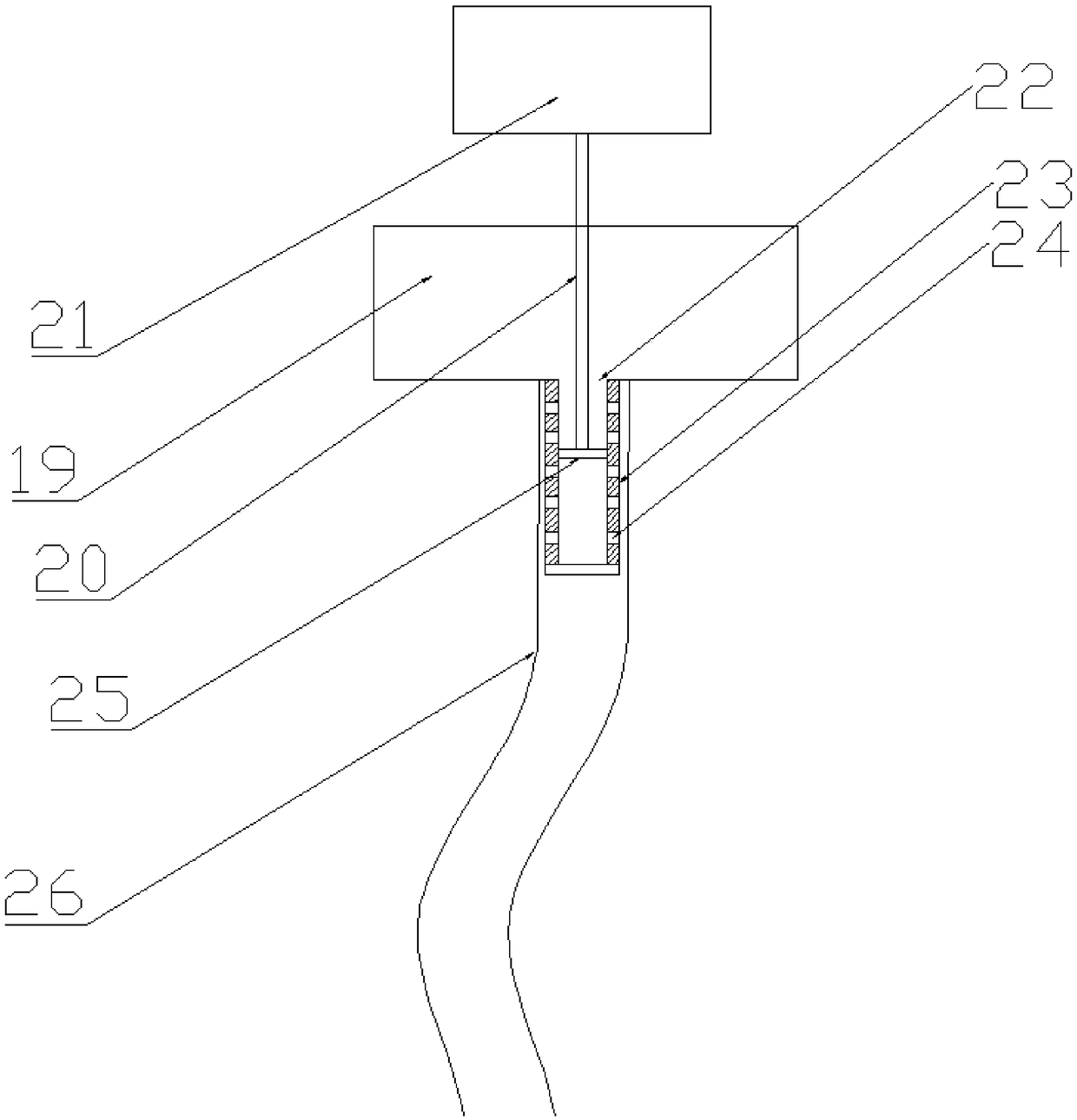

[0027] Described console 1 is provided with four circularly distributed first rotating rods 5, and the upper end of the first rotating rod 5 is provided with support frame 3, and the middle part below support frame 3 is provided with the second rotating rod 6, and the second rotating rod 6 passes through The transmission belt is connected to the output shaft of the rotating motor 4; the bottom ends of the first rotating rod 5 and the second rotating rod 6 are connected to the console 1 through the bearing 7; the top of the support frame 3 is provided with a circular movable pressure plate 8, The outer side of the upper surface of the circular movable pressing plate 8 is provided with a draw-in groove 9 along the circumferential direction of the circular movable pressing plate 8, and the circular m...

Embodiment 2

[0030] Such as figure 1 As shown, the circular fixed platen 17 is connected to the bottom of the first telescopic rod 15 through the buffer plate 16, and the bottom of the circular fixed plate is symmetrically provided with four cards, 27; Below, the inner diameter of the card slot 9 is equal to the outer diameter of the card post 27;

[0031] When this embodiment is used, the circular fixed platen 17 and the circular movable platen 8 are connected together through the clamping column 27 and the clamping groove 9, which can prevent the platen from moving during the pressing process, thereby ensuring the stability of the pressing.

Embodiment 3

[0033] Such as figure 1 As shown, 4-6 heat fans 13 are arranged around the collection tank 12, and the heat fans 13 are located on the support frame 3;

[0034]When the present embodiment is in use, a hot fan 13 is arranged around the liquid outlet funnel 11 to heat the liquid outlet funnel 11 and the circular movable platen 8, so as to prevent excess glue from solidifying and losing fluidity, and cannot enter the collection tank 12 for recycling. ; This structure can ensure the fluidity of the excess glue, thereby ensuring that the excess glue can be recycled from the points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com