Full-automatic battery aluminum shell ultrasonic cleaning equipment

A technology for battery aluminum shells and cleaning equipment, which is applied to lighting and heating equipment, cleaning methods and utensils, cleaning methods using liquids, etc., and can solve problems affecting battery quality, automation, low cleaning efficiency, and difficult cleaning effects. , to save energy and cleaning fluid, to set up reasonable cleaning process, and to save water for rinsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is further described.

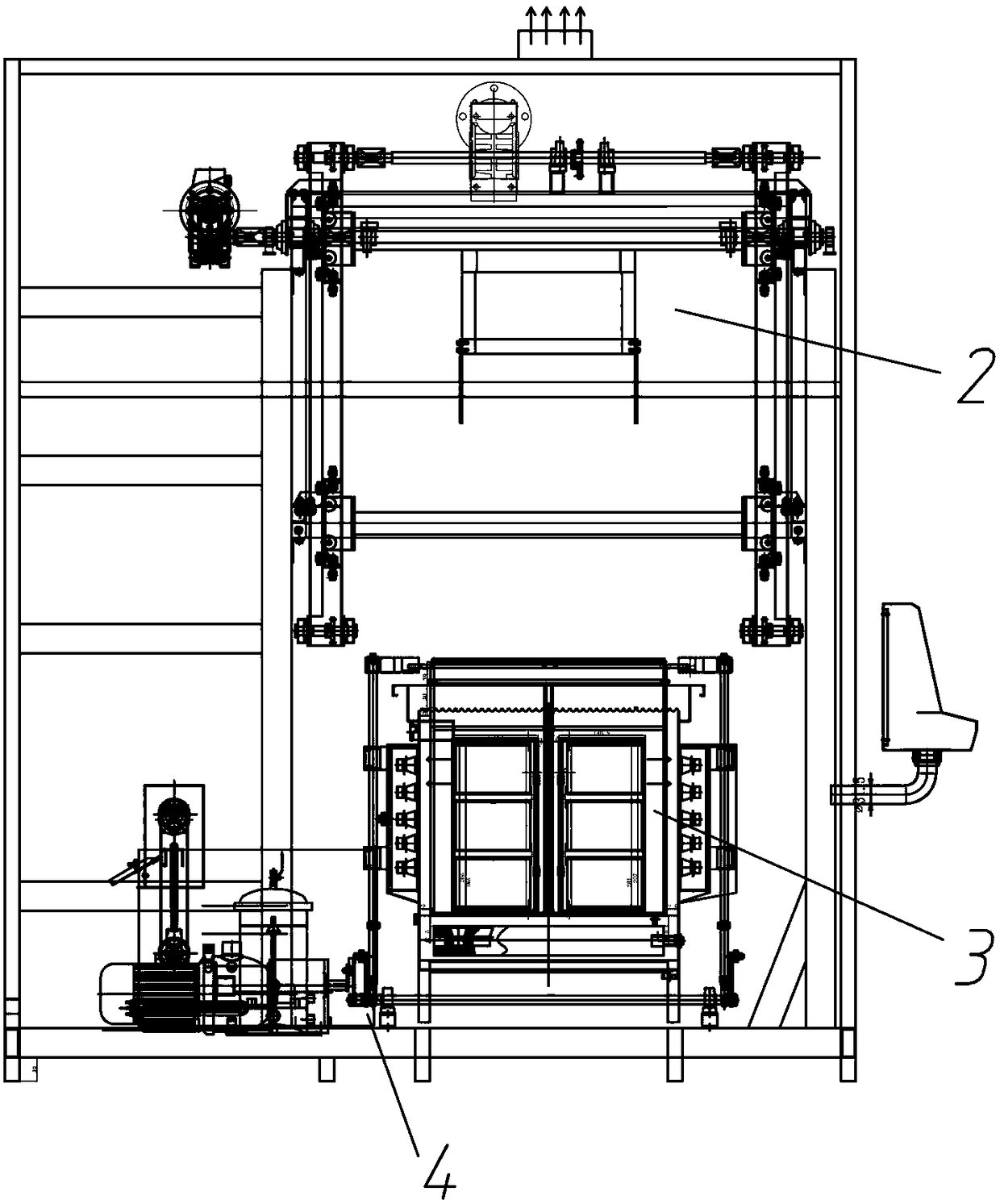

[0027] refer to Figure 1 to Figure 5 The full-automatic ultrasonic cleaning equipment for battery aluminum casings shown includes a drying oven, a cleaning basket 1 for loading battery casings, a mechanical arm 2 for conveying the cleaning basket, and a number of cleaning tanks 3 arranged in sequence. end of slot 3.

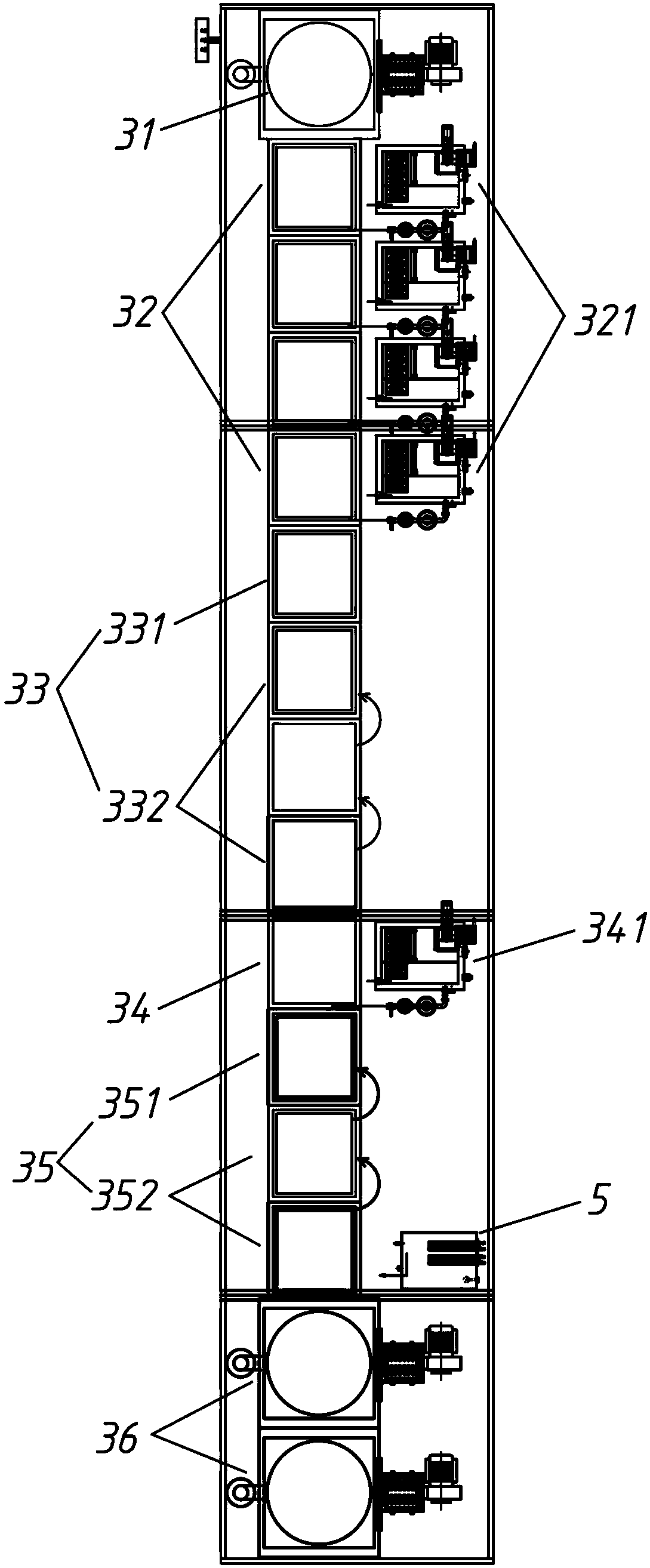

[0028] Described cleaning tank 3 comprises deoiling tank 31, coarse cleaning tank 32, front rinse tank 33, blackening tank 34, rear rinse tank 35 and dehydration tank 36 distributed in sequence; Throwing mechanism 4;

[0029] The deoiling tank 31 and the dehydrating tank 36 are all equipped with a rotating centrifugal device and a hot air device;

[0030] Described coarse cleaning tank 32 comprises several groups arranged in sequence, is used for containing cleaning liquid, is all provided with ultrasonic vibrating device and heating device in each rough clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com