Calorimetric reaction container applied to high-precision calorimetric instrument

A reaction vessel and calorimeter technology, which is applied in the field of calorimetric reaction vessels of high-precision calorimeters, can solve problems such as large deviations in scientific research requirements, low measurement accuracy, and poor sealing of bottle mouths, and meet scientific research requirements, Easy to replace and use, and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

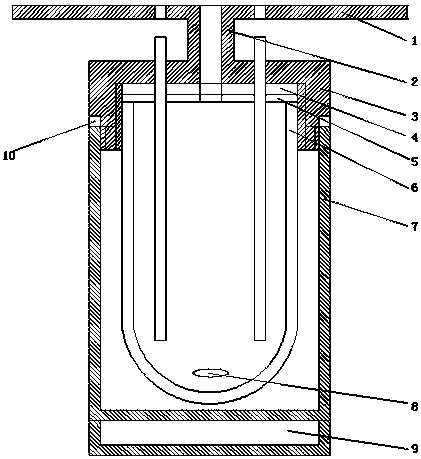

[0029] Such as figure 1 As shown, the calorimetric reaction vessel for high-precision calorimeters of the present invention includes a heat-insulating shell 7, a double-layer silver-plated vacuum Dewar 6, and an "I"-shaped container cover.

[0030] The upper part of the heat insulation shell is open and the lower part is sealed.

[0031] The double-layer silver-plated vacuum Dewar flask is placed in an insulated shell with air insulation between the two. A stirring bar 8 is arranged at the inner bottom of the double-layer silver-plated vacuum Dewar flask.

[0032] The "I"-shaped container cover includes a bracket 1 and a cover 3 . The bracket is located above the cover. The hollow connecting pipe 2 is fixedly connected between the bracket and the cover. The bracket is used to place above the constant temperature water tank of the calorimeter to sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com