Preparation method and preparation system of inulin

A preparation system and inulin technology, which are applied in the field of inulin preparation methods and preparation systems, can solve problems such as reducing product economic benefits, increasing environmental protection pressure, and generating desalination wastewater, thereby reducing subsequent concentration costs, reducing equipment costs, and increasing products. effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

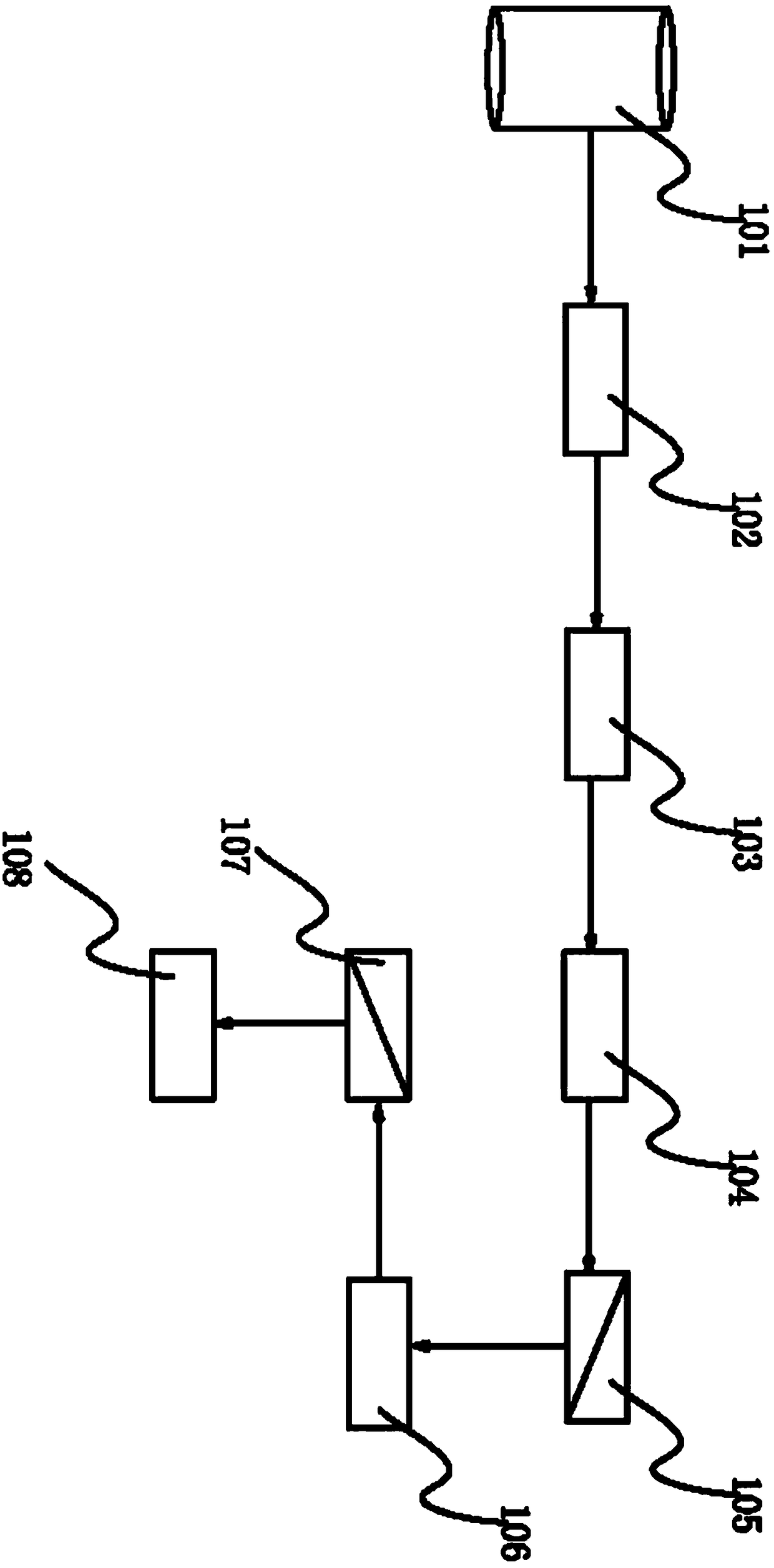

Image

Examples

Example Embodiment

[0030] Example 1

[0031] Take the Jerusalem artichoke extract and treat it with Ca(OH) 2 -CO 2 After impurity removal and clarification and activated carbon decolorization, the solid content in the material liquid is 10%, the calcium ion content is 1000ppm, and the conductivity is 7000us / cm; after the material liquid is softened by the resin, the conductivity is 10000us / cm and the calcium ion content is 50ppm; After the softened material liquid is filtered and concentrated with a nanofiltration membrane with a molecular weight cut-off of 150 Daltons and eluted with water, the solid content in the material liquid is increased to 24%, the conductivity is reduced to 4000us / cm, and the monosaccharide content is reduced to 5% When the following, continuous ion exchange desalination and decolorization are carried out, and when the conductivity is further reduced to below 100us / cm, the solids concentration of the material liquid is 23%; then the high pressure resistance organic reverse ...

Example Embodiment

[0033] Example 2

[0034] Take the Jerusalem artichoke extract and treat it with Ca(OH) 2 -CO 2 After impurity removal and clarification and activated carbon decolorization, the solid content in the material liquid is 10%, the calcium ion content is 800ppm, and the conductivity is 7000us / cm; after the material liquid is softened by the resin, the conductivity is 8000us / cm and the calcium ion content is 35ppm; After the softened material is filtered and concentrated with a nanofiltration membrane with a molecular weight cut-off of 300 Daltons and eluted with water, the solid content in the material is increased to 24%, the conductivity is reduced to 3500us / cm, and the monosaccharide content is reduced to 5% When the following, continuous ion exchange desalination and decolorization are carried out, and when the conductivity is further reduced to below 100us / cm, the solids concentration of the material liquid is 23%; then the high-pressure resistant organic reverse osmosis membrane ...

Example Embodiment

[0035] Example 3

[0036] Take the inulin slurry and pass it to Ca(OH) 2 -SO 2 After impurity removal and clarification and activated carbon decolorization, the solid content in the material liquid is 10%, the calcium ion content is 600ppm, and the conductivity is 4000us / cm; after the material liquid is softened by the resin, the conductivity is 7000us / cm and the calcium ion content is 28ppm; After the softened material is filtered and concentrated by a nanofiltration membrane with a molecular weight cut-off of 200 Dalton and eluted with water, the solid content in the material is increased to 24%, the conductivity is reduced to 3600us / cm, and the monosaccharide content is reduced to 5% When the following, continuous ion exchange desalination and decolorization are carried out, and when the conductivity is further reduced to below 100us / cm, the solids concentration of the material liquid is 23%; then the high-pressure resistant organic reverse osmosis membrane module with a pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com