Hollow bamboo shoot shredding device

A technology of shredding and hollowing, which is applied in metal processing and other directions, can solve the problems of waste, leftovers, and different matching relationships, and achieve good shredding effect, reasonable structure, and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

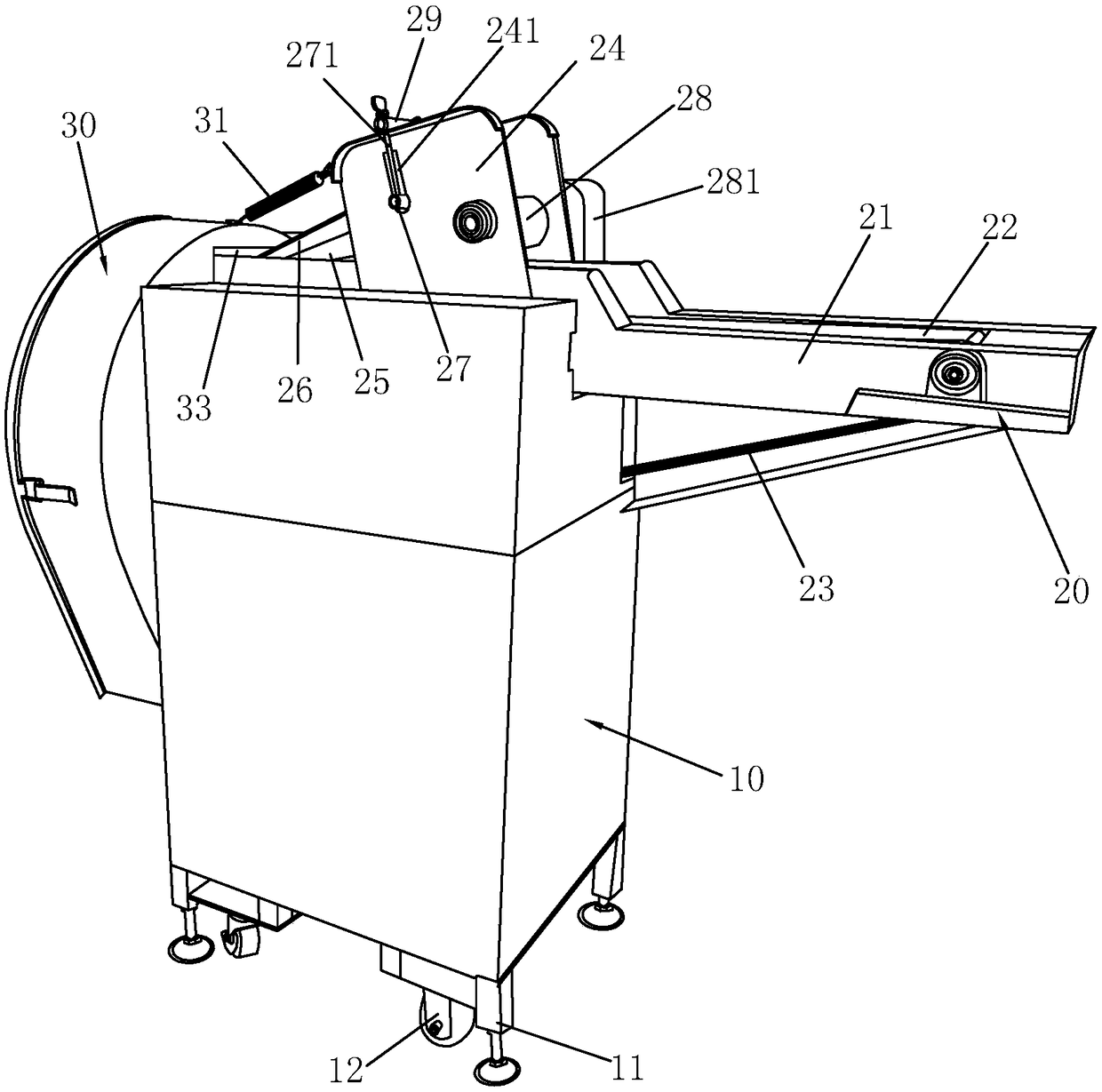

[0012] Such as figure 1 As shown, a hollow bamboo shoot shredding equipment of the present invention includes a frame 10, a driving motor (shown at the end of the figure) is provided in the frame 10, a conveying device 20 is embedded at the upper end of the frame 10, and the frame 10 There is a cutting and unloading device 30 on the side. The conveying device 20 cooperates with the cutting and unloading device 30. The conveying device 20 is used for feeding and feeding, and the cutting and unloading device 30 is used for cutting and unloading. Four support wheels 11 are provided at the four corners of the lower end of the frame 10, and universal wheels 12 are provided on the side of the support wheels 11. The four support wheels 11 are adjusted and contracted. When it is necessary to move, the support wheels 11 The contraction is supported by universal wheels 12, which are used to facilitate movement and transportation.

[0013] Such as figure 1 As shown, the conveying device 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com