Quick feeding device for milling machine

A technology of feeding device and milling machine, applied in metal processing and other directions, can solve problems such as decreased machining accuracy and product quality problems, and achieve the effect of reducing the change of placement position, high accuracy, and improving production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

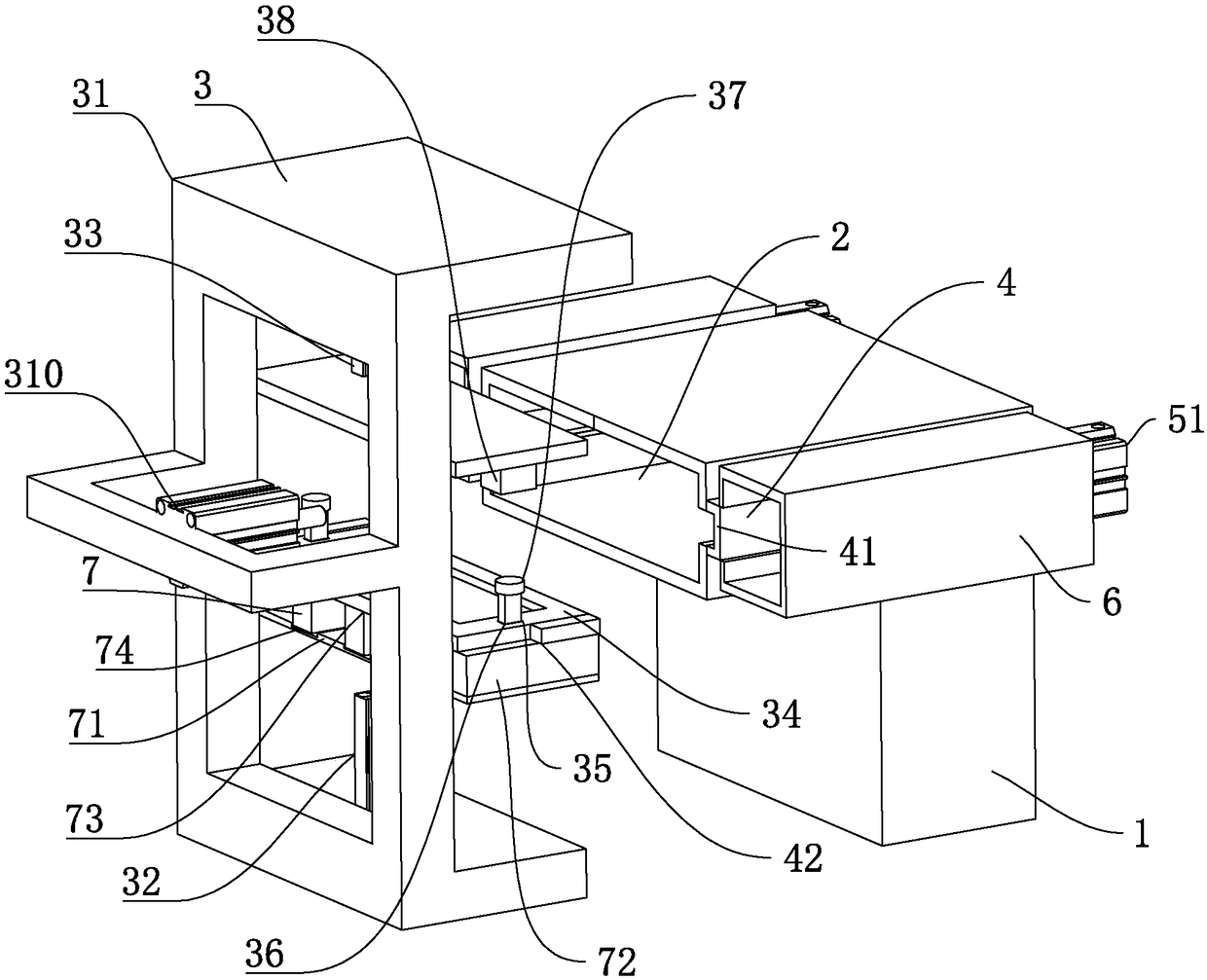

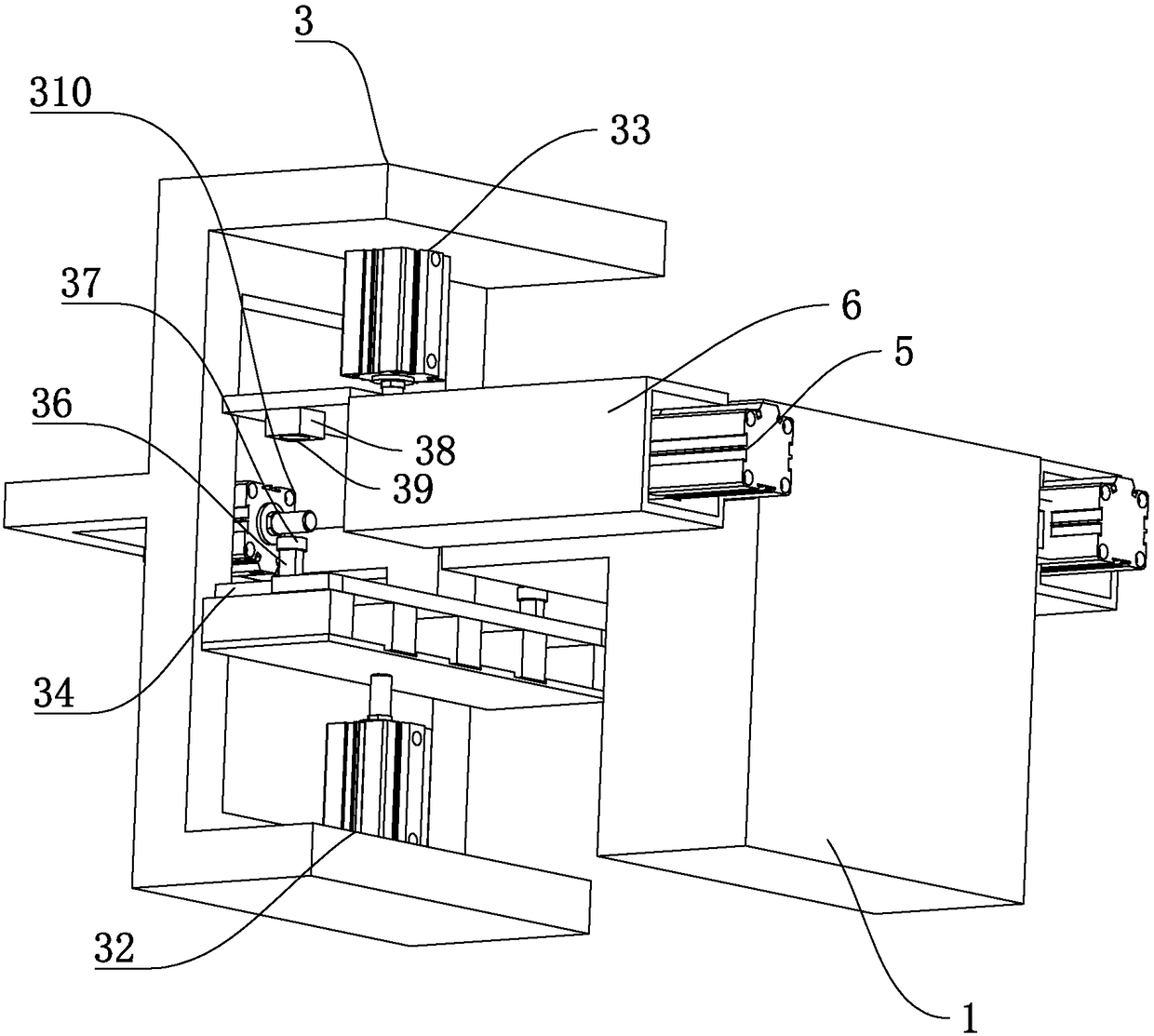

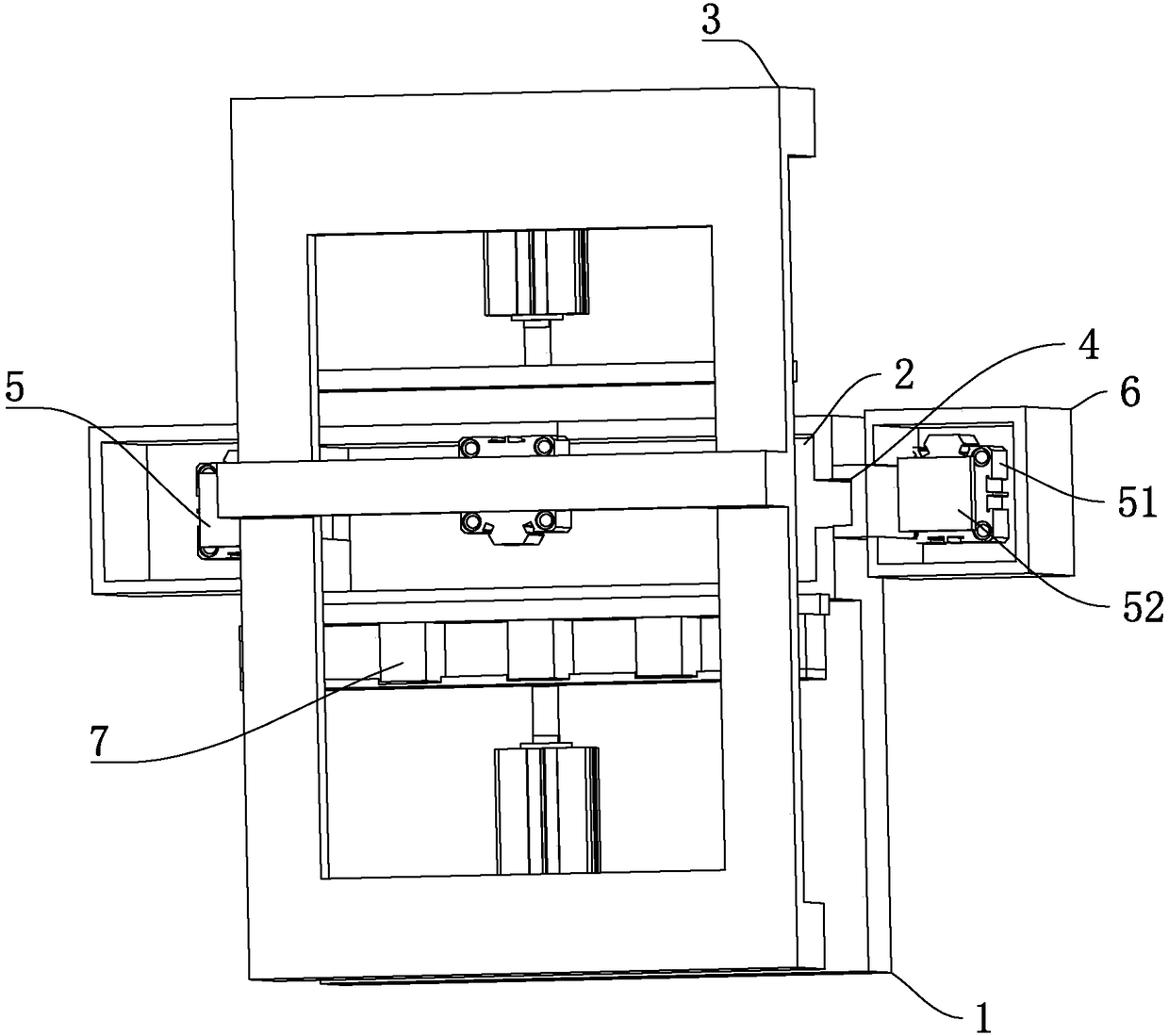

[0023] Embodiment 1: A kind of milling machine fast feeding device, such as figure 1 , figure 2 and image 3 As shown, it includes a milling machine housing 1 and a feeding port 2 positioned on one side of the milling machine housing 1, and a feeding device 3 is also provided on one side of the feeding port 2, and the feeding device 3 includes a The support 31, the bottom of the support 31 is provided with a vertically upward first cylinder 32, and above the first cylinder 32 is provided with a second cylinder 33 fixed on the support 31. The station plate 34 that the first cylinder 32 outlets is provided with, the fixture 7 is also provided between the station plate 34 and the first cylinder 32 outlets, and the fixture 7 includes a base 71 that is located at the first cylinder 32 outlets, and the base 71 Both sides of the upper surface are provided with support blocks 72 for supporting the station board 34, and a vertically upward soft insert 73 is provided between the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com