Experiental table device and experimental method for testing gap exciting force characteristic of front cover plate of centrifugal pump

A front cover, exciting force technology, applied in measurement devices, vibration testing, testing of mechanical components, etc., can solve the problem of insufficient leakage flow of the rotor system model, spending a lot of time on simulation calculations, and the impact of rotor system dynamics. Difficulties and other problems, to achieve the effect of shortening the experimental period, simple and convenient disassembly and assembly, and random combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

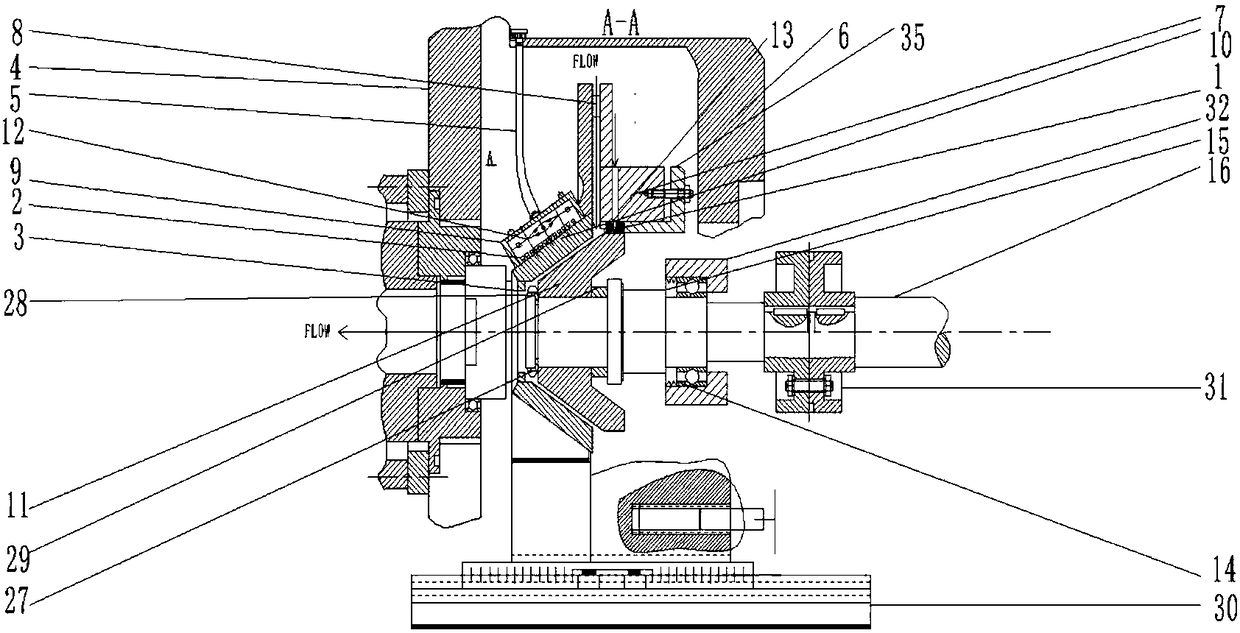

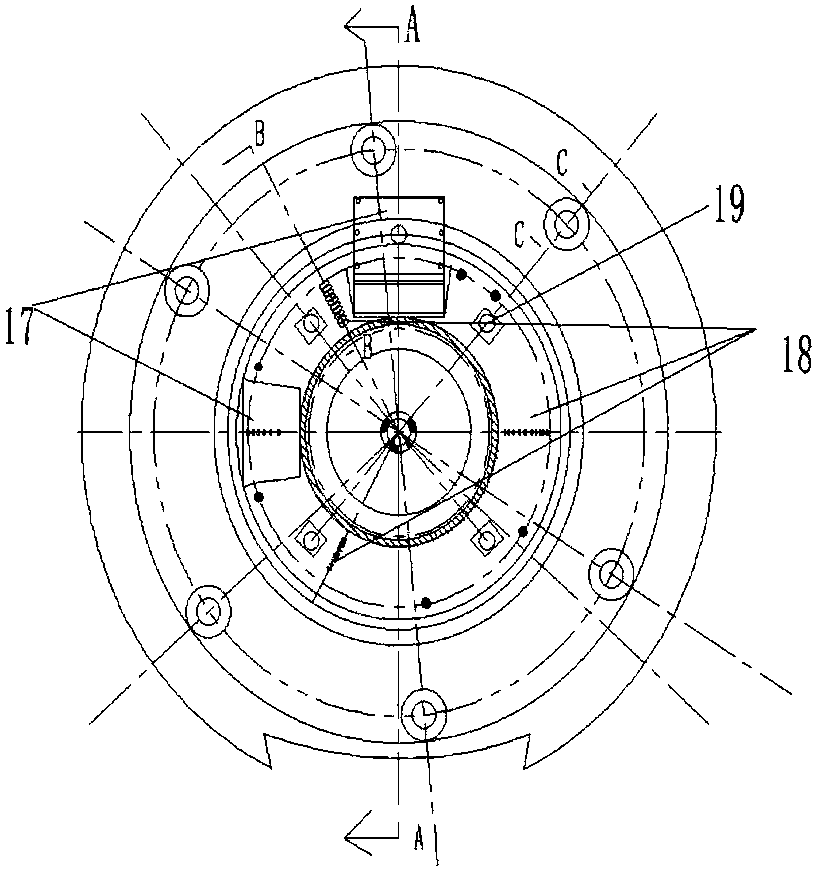

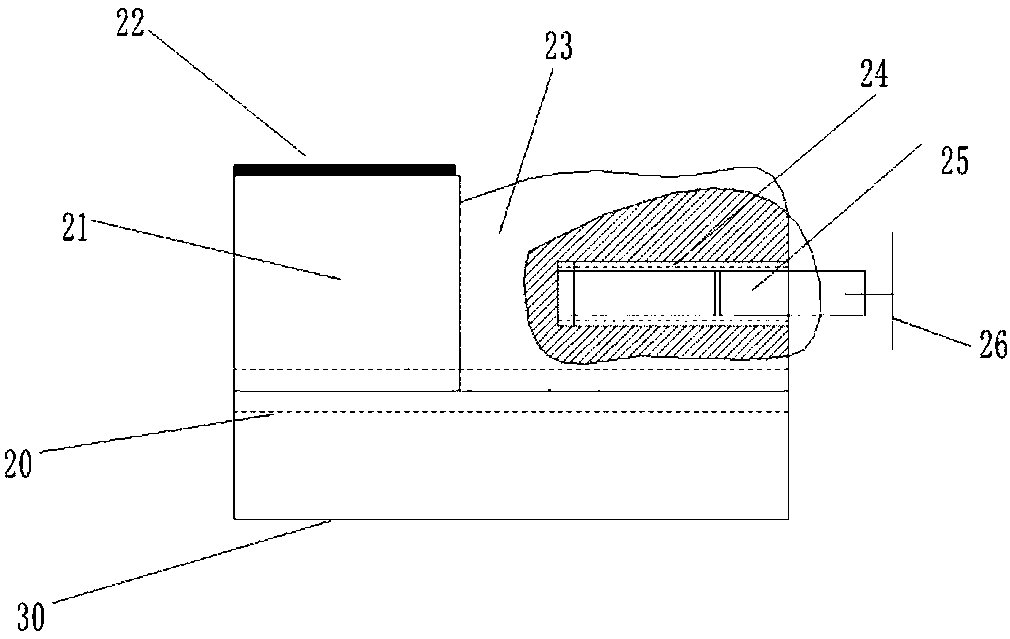

[0046] Embodiment 1. The experimental bench device used to test the excitation force characteristics of the front cover plate gap of the centrifugal pump is used to detect the force and pressure distribution caused by the leakage flow along the front cover plate 11, such as Figure 1-4 As shown, it includes packing seal 1, pressure sensor 2, sealing ring 3, sensor line pipe 5, pump casing 6, stuffing box 7, drainage tube 8, sealing box 9, housing 10, front cover plate 11, electric bridge 12, Liquid seal ring 13, sliding bearing 14, oil retaining plate 15, main shaft 16, round nut 27, stop washer 28, positioning sleeve 29, base 30, coupling 31, compression sleeve 32 and pre-tightening pressure cover 35;

[0047] The front cover plate 11 is positioned and installed on the head end of the main shaft 16 through a round nut 27, a stop washer 28 and a positioning sleeve 29, and is sealed with a packing seal set. The middle part of the main shaft 16 is equipped with an oil retaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com