Light emitting material composition and light emitting apparatus

A light-emitting material and light-emitting device technology, applied in the field of optical materials, can solve the problem of low display color gamut, and achieve the effect of widening the display color gamut and improving the display effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

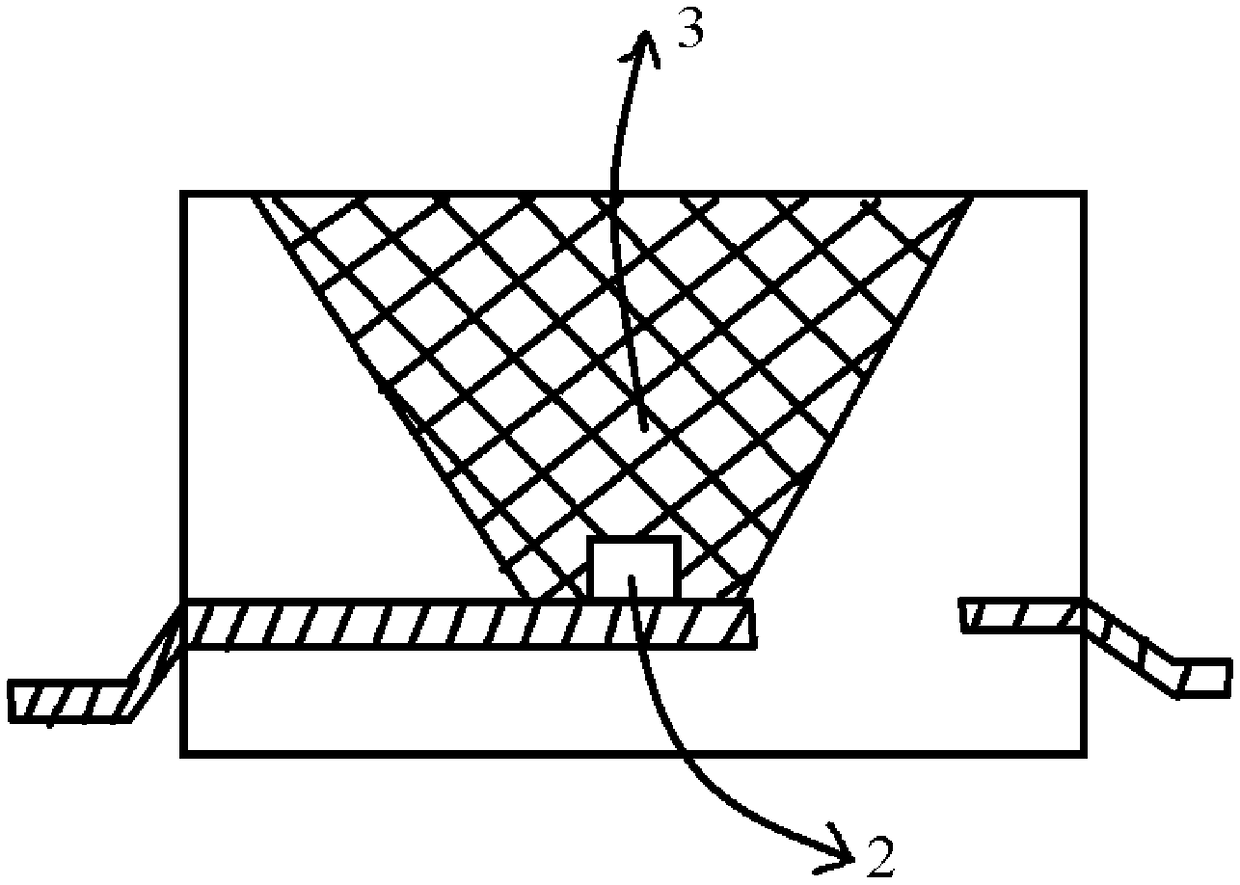

[0050] as per figure 1 The white LED lighting device of the present invention is prepared in the manner shown. Among them, the LED chip 2 is a chip with a peak wavelength at 365nm, and the blue light in the light conversion part 3 is emitted using Ba 0.85 MgAl 10 o 17 : 0.15Eu, green luminescent material adopts La 2.84 Si 6 N 11 : 0.16Tb, the red luminescent material uses 3.5MgO·0.5MgF 2 0.85 (Ge 0.9821 mn 0.0179 )O 2 0.15 / 3Si 3 N 4 . The above-mentioned blue luminescent material, green luminescent material and red luminescent material were mixed and dispersed in silica gel at a weight ratio of 30:40:30 (the weight ratio of silica gel to phosphor was 90:10) to prepare a light conversion part. The light conversion part is further assembled into an LED lighting device.

Embodiment 2

[0052] as per figure 1 The white LED lighting device of the present invention is prepared in the manner shown. Among them, the LED chip 2 is a chip with a peak wavelength at 405nm, and the blue luminescent material in the light conversion part 3 adopts Sr 4.8 (PO 4 ) 3 Cl: 0.2Eu, green luminescent material adopts Ba 0.5 MgAl 10 o 17 : 0.07Eu, 0.43Mn, red luminescent material using 3.5MgO 0.5MgF 2 0.8 (Ge 0.981 mn 0.019 )O 2 0.2 / 3Si 3 N 4 . The above-mentioned blue luminescent material, green luminescent material and red luminescent material were mixed and dispersed in epoxy resin according to the weight ratio of 25:45:30 (the weight ratio of epoxy resin to phosphor was 92:8), and the light conversion part was prepared. . The light conversion part is further assembled into an LED lighting device.

[0053] The preparation process of Examples 3-12 is basically the same as that of Example 2, using different LED chips and luminescent materials, see Table 1 for details...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com